Knowing what’s going on – and what’s coming up: SenseHUB® from BUSS turns data into real added value for compounding processes

If you know your data, you can plan smarter and react faster. For maximum production efficiency and targeted maintenance planning, condition data, OEE key figures, and integrated service are bundled in a structured manner in the networked SenseHUB platform.

Plant managers, maintenance planners, and quality managers are under increasing pressure today. Production lines should run more efficiently, maintenance should be plannable, and quality should be verifiable at all times. At the same time, the requirements for transparency, data sovereignty, and resource conservation are increasing. With its new digital platform, BUSS AG is responding to these challenges – and turning machine data into a practical tool for data-driven decisions, greater availability, less downtime, and well-founded strategies.

COMPEO is one of the most flexible compounding solutions in the industry – with a wide range of application options, energy-efficient operation, and stable processes. New COMPEO products can be equipped directly with the smart web application on request, while existing BUSS machines – including earlier generations – can be partially or fully retrofitted. With SenseHUB, this technical basis is digitally expanded: through scalable condition monitoring, performance analyses, and integrated service. This provides planning and quality managers with exactly the information they need on a daily basis for future-proof and efficient operation.

From the machine to the networked system

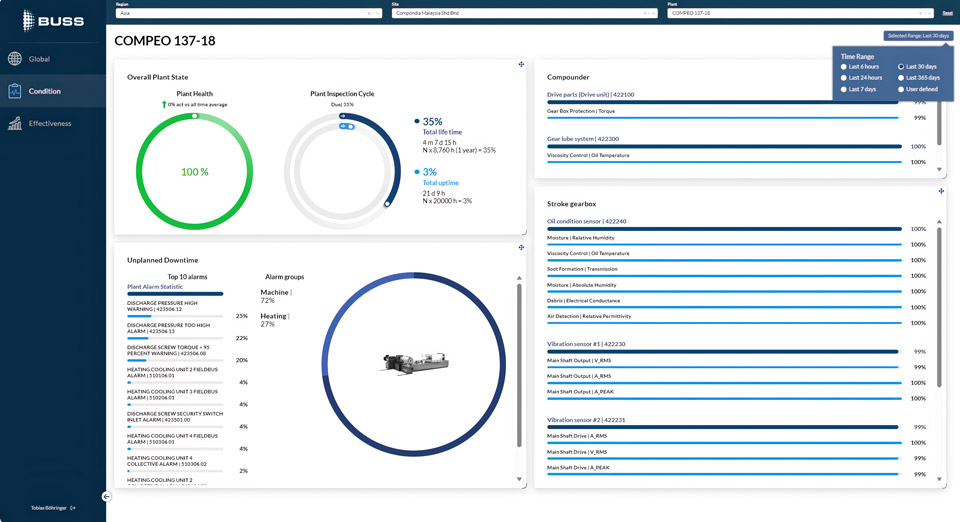

Data alone does not bring any benefits – the decisive factor is its targeted evaluation. This is where SenseHUB comes in: The platform analyzes sensor data such as vibration, oil quality, or torque in real time and provides clear status assessments via a health score. Deviations are recorded and displayed transparently. This allows preventive measures to be taken at an early stage, which saves time, reduces maintenance costs, and cuts downtime. At the same time, a smart network of man, machine and service is created, opening up new scope for action.

Screenshot from “Condition” menu item

A structured dashboard provides an overview

The dashboard provides exactly the information that decision-makers need for a better understanding of the process and maximum production efficiency:

- GLOBAL: Overview of all systems worldwide – filterable down to the individual machine

- PERFORMANCE: Detailed OEE key figures as well as energy and resource consumption

- CONDITION: Comprehensive condition analysis with visual displays as well as alarm statistics and maintenance recommendations

Service thinks along with you

The integrated service module is innovative. Anyone who recognizes a problem can open a ticket directly in the dashboard – including uploads, chat and status tracking. All information is stored in compliance with data protection regulations and transferred directly to the CRM system. This means that communication is efficient, traceable and centrally controlled.

Investing in the future – not just in the machine

SenseHUB was developed to support key production goals: ensuring product quality, increasing system availability and reducing maintenance costs. Thanks to intelligent condition monitoring and digital service processes, SenseHUB helps to detect failures at an early stage, plan maintenance as required and deploy resources in a targeted manner – for higher quality, maximum availability and lower maintenance costs.

Conditions? Fair and flexible.

The service module is available to BUSS customers free of charge. A modular pricing model applies to the IoT dashboard, which is based on demand. Pilot customers who would like to test SenseHUB on their COMPEO machine currently benefit from attractive entry-level conditions.

Interested?