A wide range of applications, a large process window, high flexibility and robustness as well as improved process stability, but also operational and user safety, energy efficiency and reduced operating costs – these are the market requirements that the new compounding system COMPEO from BUSS meets. The innovative concept of the new COMPEO compounder system consists of various components. On the one hand, there is the modular machine concept that makes the series so flexible. You could inform yourself about this in the previous newsletter. Today we present the next component that ensures maximum compounding efficiency: the new COMPEO discharge concept.

The innovative COMPEO series discharge unit uses the conveying stability of a screw pump, offering ideal pressure build-up for downstream units.

COMPEO – efficient with an innovative discharge concept

The COMPEO discharge unit ensures high overall compounding efficiency. It builds up the required pressure for downstream units such as screen changers and pelletizers optimally and reliably, independent of the mixing step in the compounder. It is based on the principle of a conical twin-screw extruder and is run in a metered mode. As a result, the entire pressure build-up takes place in the slowly rotating twin screw, which prevents temperature increases at the transition from the compounder to discharge. The working principle of a screw pump ensures that even with higher maximum conveying efficiency, also in case of higher back pressure, which means that the RPM and an associated temperature increase in temperature can be minimized.

The innovative twin-screw discharge unit of the COMPEO series is used for all processing tasks.

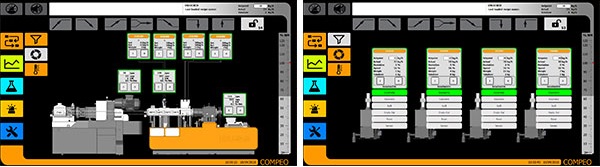

All processes can be easily controlled and monitored with the new COMPEO. The touch-screen equipped control system can be operated intuitively and is fully industry 4.0 compatible via an OPCUA interface. Defined process parameters such as temperatures, power consumption or specific energy input, and thus the efficiency of the system, are continuously monitored by the control system.

Further development in the process zone

The freely configurable COMPEO process zone opens up new process engineering possibilities through the availability of mixing and kneading elements with two to six rows of screw flights. By combining existing screw technology (three- or four-flights) with newly developed elements, the combination of high specific throughout and controllable energy which were once confliciting are now possible. The COMPEO screw geometries ensure high throughput with up to 20% lower rpm. Increasing the volume-related torque by 15% enables the configuration of longer mixing zones. That results in more stable process conditions without a higher energy input. In addition, the process window is significantly larger. Throughput can be varied in a ratio of 1:6, increasing both system flexibility and user-friendliness. It is particularly advantageous for starting up, for small production runs, and for inline-processes, where the downstream unit requires consistent product quality even with greatly varying throughput rates.

The entire system can be openend and monitored from the start screen.

- High throughputs at 20 % lower RPM

- Longer mixing zones leading to stable process conditions with low energy input

- Optimized energy efficiency through thermally insulated process section

- Monitoring of system efficiency via automated system control

The new state-of-the-art COMPEO compounder ensures greater efficiency in the processing of a wide range of products in the plastics industry – from temperature-sensitive thermosets to todemanding engineering plastics.