Compounding technology for Fluoropolymers

Fluoropolymers undoubtedly belong to the high-performance polymers. In 1938, Plunkett discovered the polymer polytetrafluoroethylene (PTFE) by chance at DuPont.

The exceptional properties of fluoropolymers were quickly recognized and are still crucial for many high-tech applications. In addition to exceptionally good chemical resistance, they have excellent electrical and thermal properties as well as being nonflammable and difficult to wet and have the lowest coefficients of friction. Most of these properties are due to the fluorine atoms present in the polymer chain.

Fluorine is the most electronegative and most reactive nonmetal in the periodic table. After hydrogen, fluorine has the smallest atomic radius among the elements. In reaction with carbon, an extremely short and strong bond is formed, which determines the extraordinary properties of the fluoropolymers. Closing the product cycle for fluoropolymers allows the up-cycling of end-of-life products as well.

Typical applications

Fluoropolymers can be divided into several subgroups:

The proportion of PTFE is about 52% of the total volume. Due to its high melt viscosity, PTFE cannot be processed thermoplastically. Fluorothermoplastics such as PVDF, PFA, FEP, etc. comprise about 36% of the product volume. The broad product group of fluorinated rubbers (FKM), which includes both the so-called bipolymers and terpolymers, forms the third subgroup with a total of 12%.

The two last-mentioned product groups are tailored to their respective applications by compounding. PTFE-containing aggregates can play a role in applications such as slide bearings.

The combination of process engineering expertise with the system-specific capabilities of the BUSS Kneader and metallurgical plant design knowledge allows the implementation of sophisticated solutions. This ranges from different proportions of conductive aggregates, and clean-room production for medical applications, to reinforcement with glass and carbon fibres for the highest mechanical loads.

Compounding requirements

The immediately effective gentle mixing processes and respective relaxation phases lead to excellent distributive mixing results, with optimal preservation of the internal structure of the conductive materials or length of fibres. The moderate shear rates of the BUSS Kneader ensure compounding in the permissible operating window without the temperature spikes that in alternative systems could lead to the formation of harmful by-products.

The design freedom of this system also makes it possible to respond specifically to the increasing viscosity in the process zones with appropriately chosen configurations. This allows customized control and regulation of the process conditions. In the two-stage BUSS Kneader system, compounding and pressure build-up are moreover consistently decoupled from each other. Thus, the compounding process, independently of pressure build-up, filtration and shaping, is optimized for the best possible results in terms of quality and throughput.

With BUSS Kneader compounding technology leadership, Buss is the ideal partner for developing and commercializing sustainable system solutions.

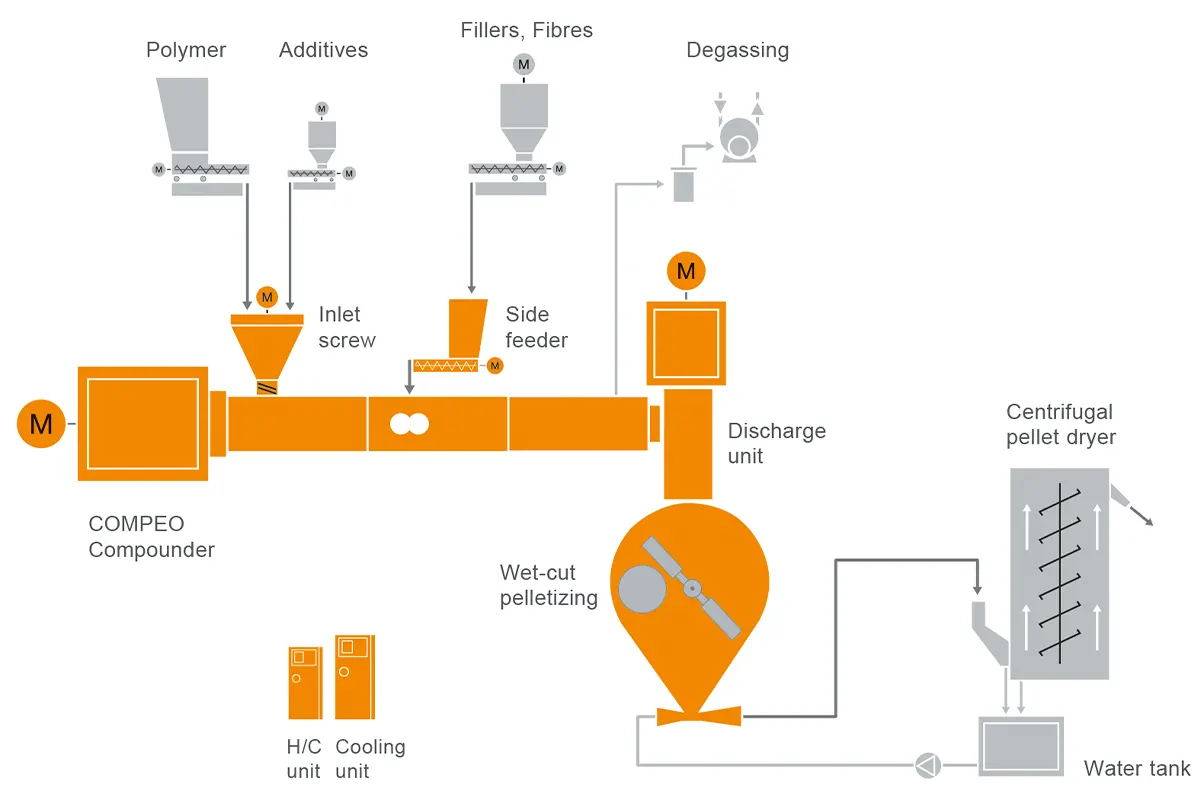

Typical plant layout for fluoropolymers

BUSS compounding systems for fluoropolymers offer the following specific benefits

Learn More

Downloads

-

COMPEO