The service offering from BUSS

Our strategically located service centers form a global service and support network. This network is staffed with well-trained specialists to ensure higher productivity and plant availability throughout the entire product lifecycle.

Additionally, the BUSS service team has a wide range of tailored service offerings that provide a comprehensive service program.

Some examples include spare parts support, field service, training of operating and maintenance personnel, process support, laboratory tests, and custom retrofit packages.

Commissioning serviceFor a smooth operational start

A well-planned and executed start is crucial for your success. Our specialists stand by your personnel throughout the entire operational duration of the plant.

Your benefits

- High plant availability

- In-depth training of your personnel to ensure optimal utilization of the plant

- Minimal installation and commissioning time or costs thanks to our project management expertise

Our commissioning services at a glance

What our customers say

“I express my sincere thanks for both of your continued support and understanding since the beginning of the project. Your hard work has laid a solid foundation for a long-term cooperation between NFC and BUSS. I hope that we can continue our sincere cooperation and make persistent efforts to provide technical service and maintenance work and make great efforts for NFC and BUSS on establishing a good reputation.”

“BUSS is an excellent partner as its compounding delivers a very good performance. Besides, the technical support from the BUSS team is perfect. BUSS means full understanding in commercial terms.”

“Since the beginning of our partnership with BUSS, PLASCOM is successfully using BUSS compounding lines to manufacture polymer compound for wire & cables.”

“BUSS is a great partner because BUSS is High Tech. Thank you for the good work.”

“BUSS is a great partner as the quality of its products and the output are high, maintenance is low and spare parts are rarely required. The BUSS compounder is a very good product and disposes of features that makes it unique.”

“BUSS helped us to regain control of our machines, we have optimized the process geometry together with technicians from BUSS and we use spare parts that are fit for purpose. Machine has over 1800 hours flawless runtime in the last 9 months.”

“After several days of stoppage due to a brake in our kneader, we have restarted the production and fortunately everything is OK. The collaboration with the BUSS team was very useful and fulfilled all of our requirements. It was a very nice experience to work together “online” with the BUSS team in Switzerland and our team in Argentina. Thank you very much for your kind and useful collaboration.”

“The BUSS Kneader is good compounding with high quality.”

Maximizing plant availabilityWith our service level agreements tailored packages for your operation

Fast response times and high-quality service ensure maximum plant availability. With our service level agreements (SLA), we offer you tailored services that minimize the risk of machine downtimes and enable a long service life and economical operation of your plant.

Your benefits

- Ensuring consistently high product quality

- Planned training of your personnel

- Extending the lifespan of your investment

Our services at a glance

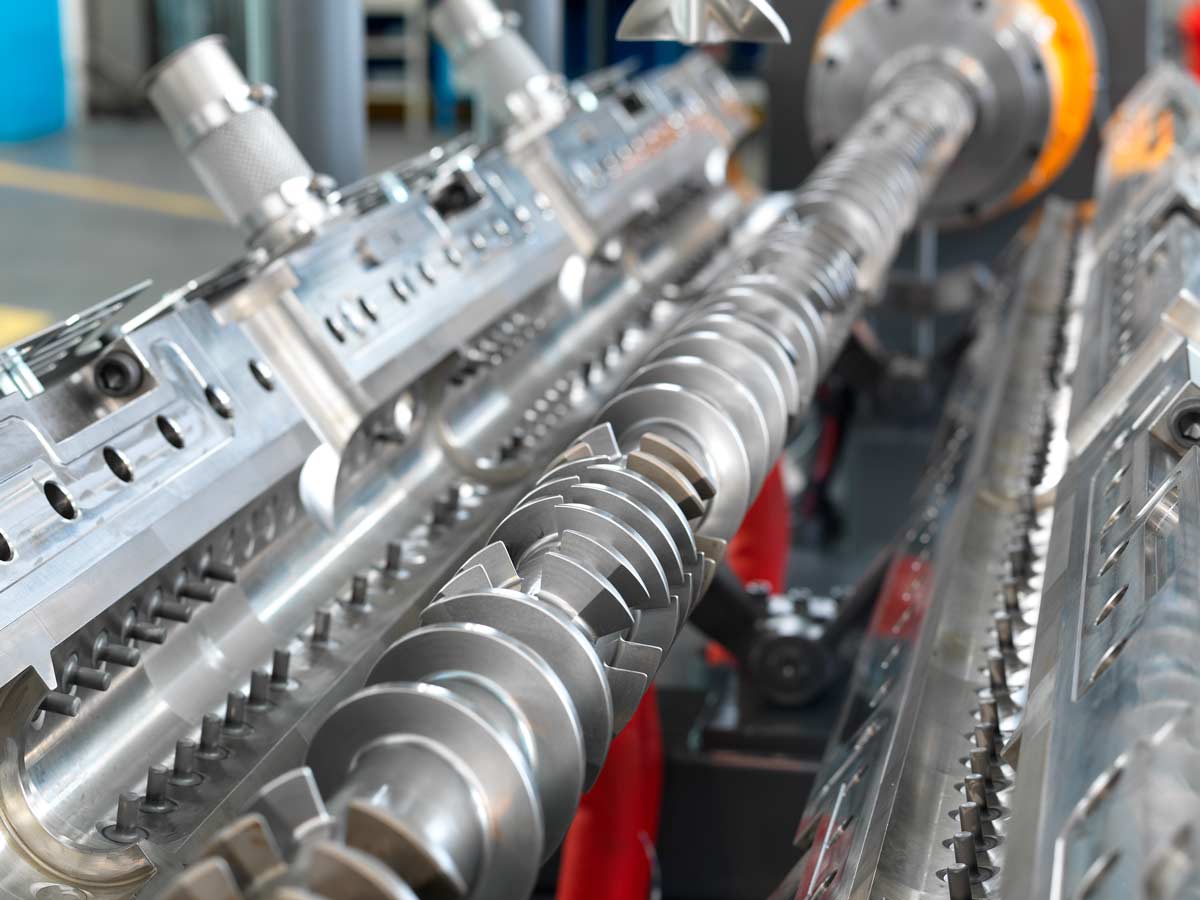

ModernizationFeatures for performance enhancement

By keeping your system up to date with the latest technology, its maximum efficiency is ensured. We want to help you achieve maximum performance with our latest developments and train your staff in using these upgrades.

Your benefits

- Improvement of product quality

- Extending the lifespan of your investment

Our services at a glance

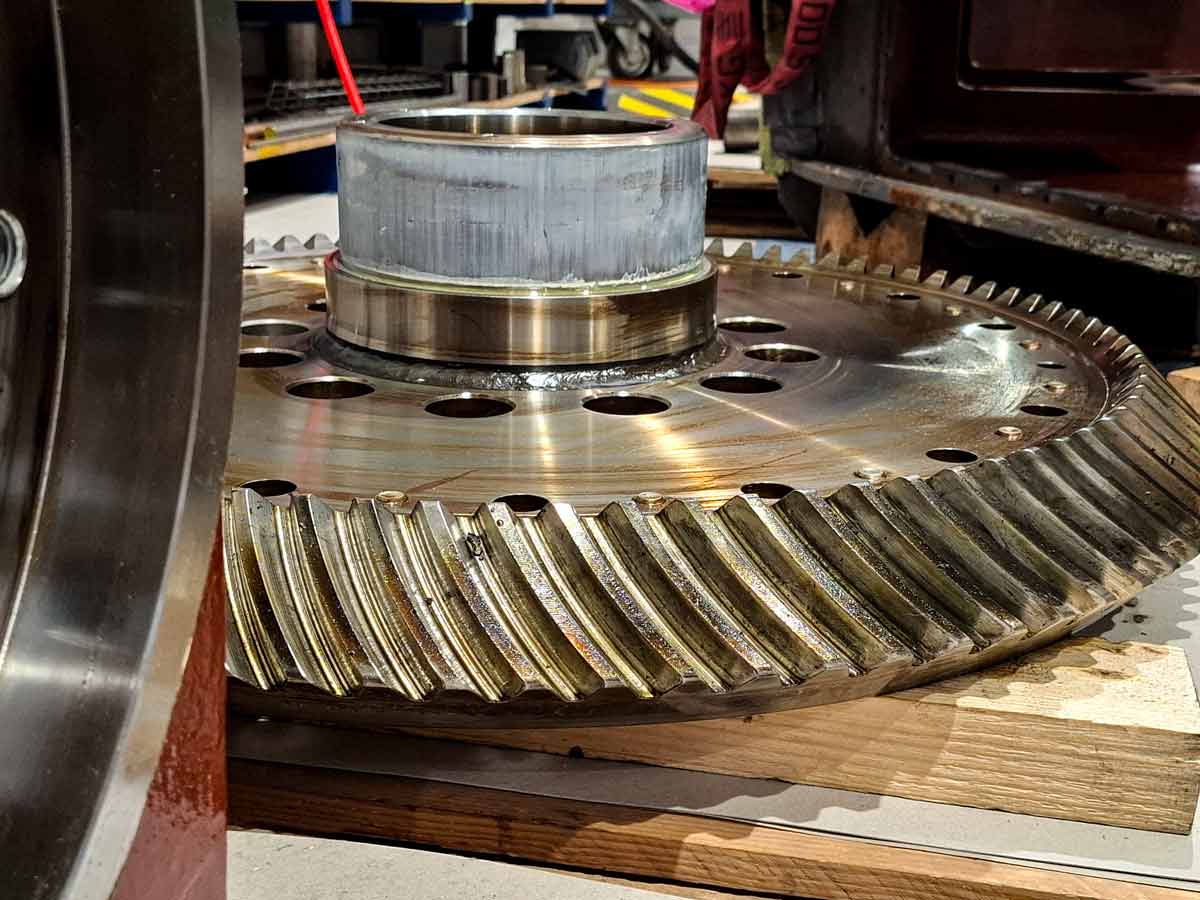

Reevaluation of your machineDecommissioning, overhaul, or replacement

Keep your plant up to date with the latest developments to maximize efficiency. As plants age, they may require increased maintenance to maintain their reliability. Our service staff can conduct a review of your system and offer you options such as phased decommissioning, complete overhaul, or replacement.

Your benefits

- Longer lifespan of the plant

- An overhaul with extended operation is more cost-effective than a new acquisition