BUSS PCS Co-KneadersThe specialist for powder coatings & thermosets

BUSS compounding technology developed further for optimized performance

The PCS is a further development of the classical BUSS Co-Kneader, specifically for the use of powder coatings and thermosets. While it retains the proven operating principles of the BUSS Co-Kneader, the process section in particular has been developed for the requirements of modern formulations.

The extended BUSS Co-Kneader series PCS sets benchmarks for profitability, availability and user-friendly handling. Its extended process length and increased screw speed enable optimum quality powder coating formulations with the same configuration, simply by adjusting the process parameters.

BUSS PCS Co-Kneaders are also highly suitable for processing thermosets. In order to exploit the superlative qualities of EMC, compounding systems must ensure excellent dispersion of the high filler content at low and perfectly controlled temperatures.

BUSS compounding technology has routinely met these high requirements for 60 years and is equally ideal for epoxy-based, phenol-based, polyester-based, melamine and urea-based resin molding compounds.

Our long-standing experience enables the optimum selection of the materials in order to minimize machine downtimes and maintenance work.

BUSS PCS Co-KneadersFocus on customer benefits

Properties & benefits

Efficient service concept

We advise you comprehensively in selecting your most suitable BUSS Co-Kneader, while always remaining flexible and customer-oriented. Thus, we can integrate our PCS Co-Kneader into your existing production plant as an individual unit or also work our way through the entire line with you from pre-mixing to the cooling belt in order to find the ideal individual solution for your needs.

The BUSS service team is available to you worldwide for professional support in handling your compounding system. From project engineering via process support consultation, installation and commissioning, to training and exemplary service, we partner you in securing your long-term investment. This also incorporates retrofitting, overhaul, relocation or modernization of your compounding systems.

Technical data

Throughput rates [kg/h] | up to 40 |

Feeding Device | |

Type | Inlet hopper |

Hopper Volume [l] | 1 |

Side Feeder Screw Diameters [mm] | - |

Drive Rating [kW] | - |

BUSS Kneader | |

Process Length | 11 or 14 L/D |

Screw Diameter [mm] | 30 |

Screw speed max. [rpm] | 500 |

Heating capacity [kW] | 6 |

Drive rating max. [kW] | 5.5 |

Throughput rates [kg/h] | 250 |

Feeding Device | |

Type | Inlet hopper |

Hopper Volume [l] | 3 |

Side Feeder Screw Diameters [mm] | - |

Drive Rating [kW] | - |

BUSS Kneader | |

Process Length | 11 or 15 L/D |

Screw Diameter [mm] | 46 |

Screw speed max. [rpm] | 650 |

Heating capacity [kW] | 2 x 9 |

Drive rating max. [kW] | 30 |

Dimensions (Explanations Below) | |

Length (L1) [mm] | 2 200 |

Length (L2) [mm] | 3 500 |

Width (W1) [mm] | 600 |

Width (W2) [mm] | 2 200 |

Height (H1) [mm] | 1 200 |

Height (H2) [mm] | 1 500 |

Throughput rates [kg/h] | 700 |

Feeding Device | |

Type | Side Feeder |

Hopper Volume [l] | 50 |

Side Feeder Screw Diameters [mm] | 40 |

Drive Rating [kW] | 1.1 |

BUSS Kneader | |

Process Length | 11 or 15 L/D |

Screw Diameter [mm] | 70 |

Screw speed max. [rpm] | 650 |

Heating capacity [kW] | 2 x 12 |

Drive rating max. [kW] | 65 |

Dimensions (Explanations Below) | |

Length (L1) [mm] | 2 800 |

Length (L2) [mm] | 11 000 |

Width (W1) [mm] | 2 100 |

Width (W2) [mm] | 3 500 |

Height (H1) [mm] | 1 300 |

Height (H2) [mm] | 2 400 |

Throughput rates [kg/h] | 1500 |

Feeding Device | |

Type | Side Feeder |

Hopper Volume [l] | 130 |

Side Feeder Screw Diameters [mm] | 60 |

Drive Rating [kW] | 2.2 |

BUSS Kneader | |

Process Length | 11 or 15 L/D |

Screw Diameter [mm] | 100 |

Screw speed max. [rpm] | 650 |

Heating capacity [kW] | 2 x 12 |

Drive rating max. [kW] | 110 |

Dimensions (Explanations Below) | |

Length (L1) [mm] | 4 500 |

Length (L2) [mm] | 13 500 |

Width (W1) [mm] | 2 700 |

Width (W2) [mm] | 3 600 |

Height (H1) [mm] | 1 500 |

Height (H2) [mm] | 2 900 |

1 Premix discharge station

2 Side feeder

3 Process section

4 Main drive

5 Heating/cooling units

6 Gear box

7 Cooling rolls

8 Crusher

9 Control cabinet

10 Drive cabinet

More detailsabout BUSS Co-Kneaders PCS 30 and PCS 46

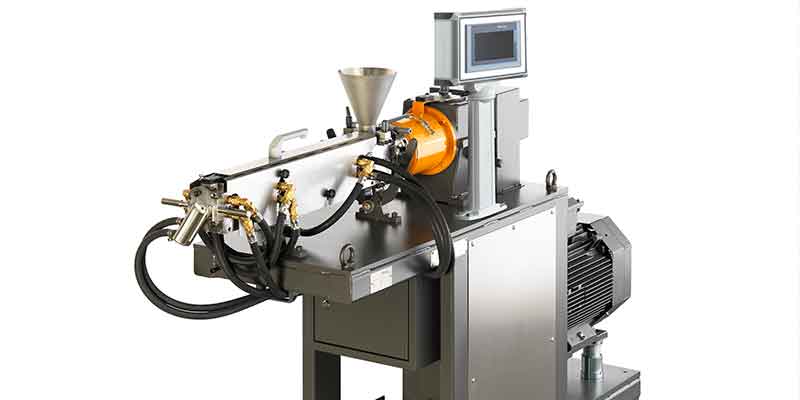

Pilot plant PCS 46 15R

The BUSS Co-Kneader PCS 46 is a versatile, compact small-scale compounder for challenging R&D work and pilot runs. This economical, user-friendly small batch compounder has similar process properties to the large production-scale BUSS Co-Kneaders, with output rates of up to 250 kg/h.

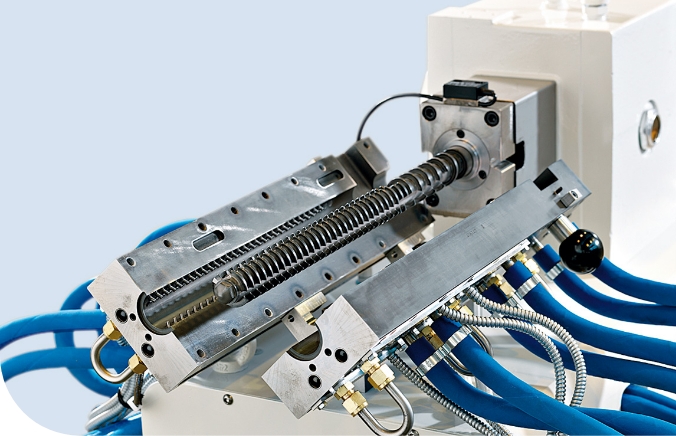

Thanks to the modular processing zone, all production process conditions can be precisely emulated. The split barrel design enables not only optimal access to all process parts, but also the visual assessment of all individual steps along the processing zone.

Laboratory Co-Kneader PCS 30

The BUSS laboratory Co-Kneader PCS 30 is a versatile, compact small-scale compounder for research and development, color matching and customer sample production.

This economical, user-friendly laboratory compounder has similar process properties to the large production scale BUSS Co-Kneaders, with outputs ranging from 300 g for samples up to 40 kg/h. Based on its process scale-up capabilities it is predestined as a universal laboratory compounder offering a high degree of efficiency and flexibility.