Compounding technology for

Polybutylene terephthalate (PBT) and

Polyethylene terephthalate (PET) Compounds

PET and PBT polymers belong to the polyesters family. PET can be in the form of an amorphous moulding compound (PET-A) or a semicrystalline material (PET-C). PBT is considered to be partially crystalline. Both PET and PBT are thermoplastics and produced by polycondensation. They belong to the group of technical synthetics, often called engineering plastics. This is due to their main strengths and application fields: for technical or engineering components with challenging mechanical, thermal and electrical requirement profiles, and chemical resistance.

PET / PBT were first mass-produced in England in the 1940s. Their original uses in textiles and fabrics of all kinds have been extended to injection moulding and extrusion applications. Due to its faster crystallization, PBT is mainly used for injection moulding applications. PBT compounds optimally combine stiffness and strength with good toughness and heat resistance as well as dimensional stability, even in challenging environments. This makes them an important material in the electronics/electrical, automotive and aerospace industries among others, with predicted growth of 5-7% p.a.

Typical applications

The main applications of PET (Polyethylene terephthalate) are for fibers (65%), packaging (about 29%), foils (4%) and specialities (2%). For specialities, the compounding process plays a particularly important role.

The individual property profiles are achieved by means of reinforcements, fillers and flame retardants among other additives, as well as elastomer modifications. Above all for PBT (Polybutylene terephthalate), the temperature and shear sensitivity must be taken into account in the compounding technology. PET and PBT are also used as blend partners in tailor-made compounds.

Compounding requirements for PBT and PET

Compounding these polymers is correspondingly challenging. The polymer components and, if appropriate, blend components, have to be melted gently and homogeneously without shear peaks, and the filler and flame retardant fractions must be excellently distributed. This is very demanding for the compounded technology. The reinforcing fibers must be added in such a way that the mechanical properties are maximized while at the same time ensuring long dwell times in the respective process zones.

These partially conflicting requirements are well mastered by sophisticated techniques. The BUSS Co-Kneader has long proven itself in compounding these demanding materials. The moderate and uniform shear rates, also specifically adaptable if necessary, and thus precise temperature control of the BUSS Kneader play the key role here: in the melting zone, only as much energy as necessary is dissipated without overstraining the polymeric components. The fillers and flame retardants are distributed optimally within the shortest process length due to the high folding rates. Downstream, if necessary, the reinforcing fibers are added to them, isolated and then sheathed so as to preserve the maximum fibre lengths. Important market players rely exclusively on the specific advantages offered by the BUSS Kneader technology in this field.

The BUSS Co-Kneader’s two-stage system systematically separates the compounding and pressure build-up stages so that each of them can be independently optimized. Together with the broad-based BUSS process expertise around the PBT and PET compounding technology, the modular and thus adaptable design of the entire system make the BUSS system an excellent choice for compounding the wide range of PET and PBT compounds.

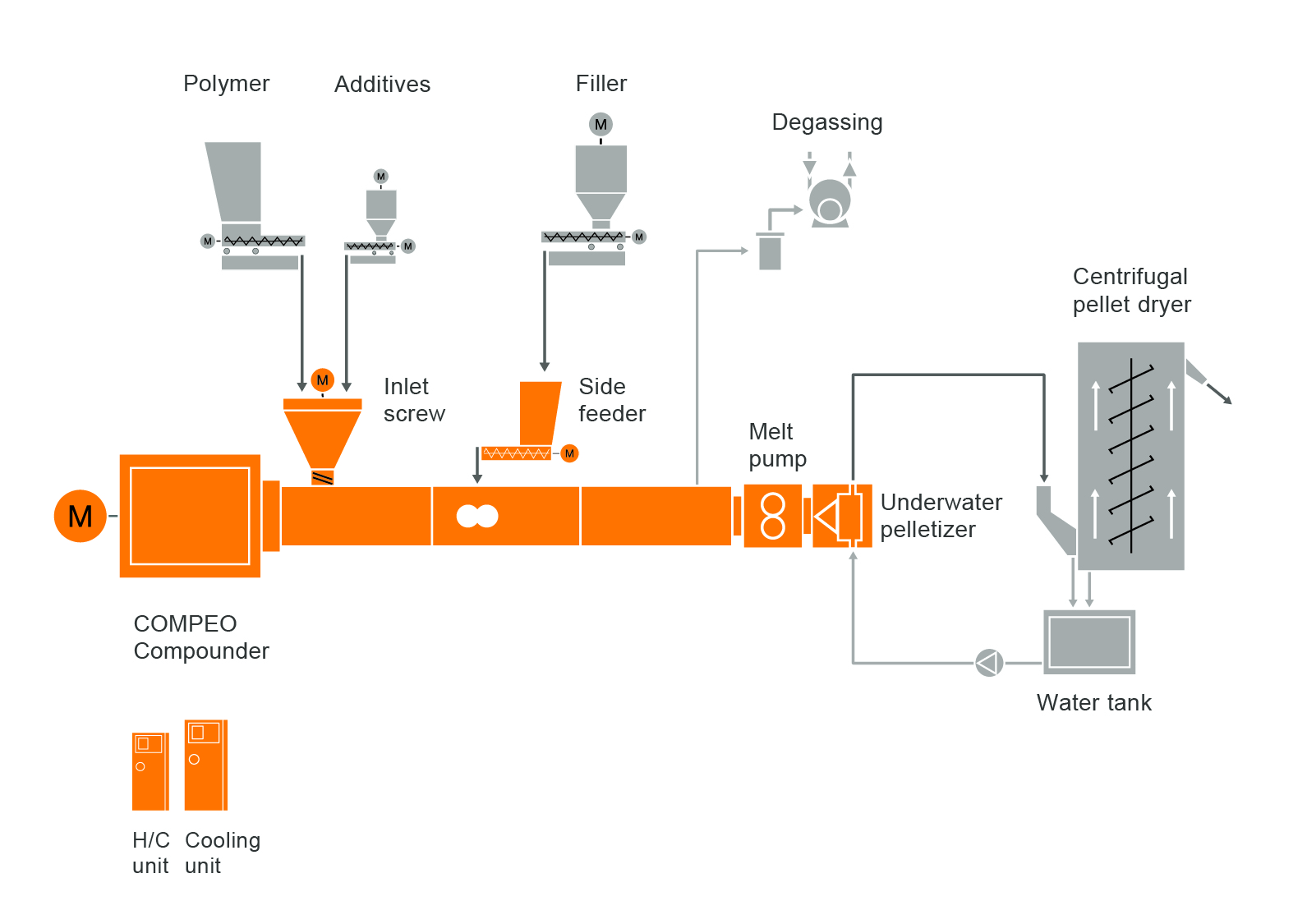

Typical compounding plant layout for PBT / PET

BUSS compounding systems offer the following specific benefits

Learn More

Typical plant layout for PBT and PET

Downloads

-

COMPEO