Raw signals do not prevent downtime. Decisions do. SenseHUB® turns live machine data into practical guidance for operations, maintenance, and service, in real time and across locations.

SenseHUB®connects machine, data and service. For maximum uptime and service quality.

At a glance

Overview of what you get when using the SenseHUB® platform:

Why uptime sufferswhen insight is delayed

In compounding, process stability is rarely lost in one single moment. It usually starts with small deviations: a shift in load, a temperature trend outside the normal corridor, a change in vibration behaviour, a subtle drift in energy input. If these signals are not visible, contextualized, and shared across teams, they remain “noise” until they become downtime, scrap, or quality variation.

Many production environments still face the same structural gap: data exists, but it is not connected to decisions and workflows. What changes with connected insight: deviations are detected earlier, actions become targeted, and collaboration becomes traceable, from first signal to service resolution.

1

Limited operational visibility

Key indicators are not available in real time or not presented in a way that highlights deviations early. As a result, issues are detected late, and root-cause analysis becomes time-consuming.

2

Maintenance without condition-based prioritization

Without continuous condition monitoring, maintenance follows fixed intervals or ad-hoc judgment. That leads either to unnecessary interventions or to late interventions, both of which reduce availability and increase cost.

3

Service processes without a single source of truth

When service communication and documentation are split across emails, calls, and local files, knowledge is lost. Escalations take longer, responsibilities are less clear, and resolution speed suffers.

From data to actionSenseHUB® in daily operations

SenseHUB® is designed to create real value from raw machine data. Not by adding another digital layer, but by translating signals into operational clarity and structured service execution.

In practice, this means three things:

- Condition and performance are visible in context

Instead of isolated values, you see what changed, how fast it changed, and whether it is moving away from stable operation. - Deviations become actionable early

Health indicators, alarm analytics, and recommendations help you prioritize interventions before small deviations turn into quality variation or downtime. - Service is integrated into the same workflow

When an issue occurs, it can be documented and handled directly within the dashboard, with machine context, history, and communication in one place.

SenseHUB® supports plant managers and quality managers with a clear, real-time view of machine performance, utilization, and maintenance requirements. Locally or across sites, the goal stays the same: fewer surprises, faster alignment, and more predictable uptime.

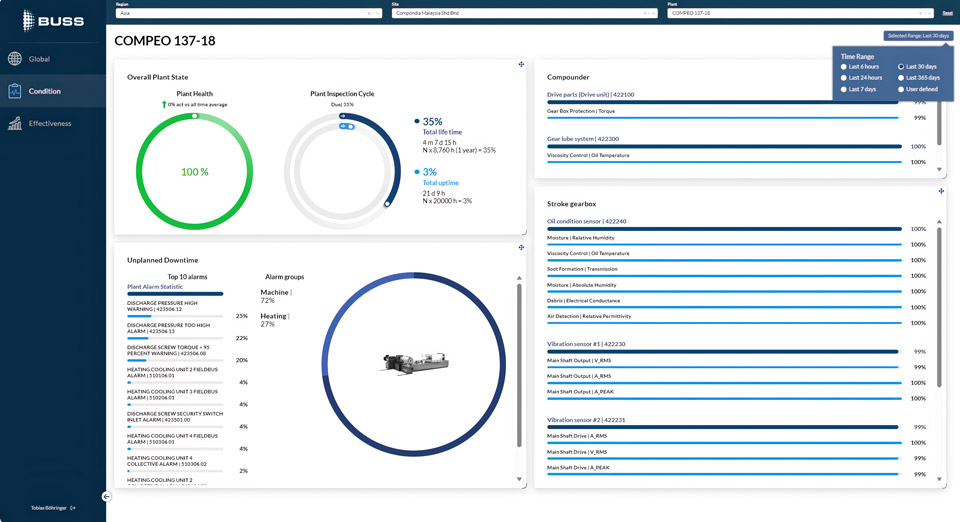

SenseHUB® dashboard closes the gapfrom machine to insight

One platform. All insights.

SenseHUB brings together what teams typically have to collect from different sources: condition signals, performance KPIs, and the service context around an event. The platform is structured so you can move from overview to detail quickly, and from observation to action without losing time in handovers.

Instead of isolated values, you get four complementary perspectives, aligned with daily workflows across operations, maintenance, quality, and service.

What changeswhen SenseHUB® is in place?

SenseHUB helps teams reduce uncertainty and improve response quality. Instead of reacting to failures, you gain early signals, clear priorities, and structured processes.

Operations

Service & Maintenance

Management

SenseHUB® isn’t just another monitoring tool. It’s a platform that lets you stay in control – not just informed. Built by engineers, for engineers. Ready for today’s demands and tomorrow’s expectations.

Get in touch with our SenseHUB® team!

To get more information about SenseHUB® or an individual consultation, or to book a dashboard demo, please complete the form below. We will contact you shortly.