Experiments with our customers are necessary and effective due to very different problem situations:

- Product development (determining the formulation) with the customer

- Feasibility and quality issues in existing production

- Unknown risks and process parameters before building new plants

- Feasibility/manufacturability of new products is not proven

- Process engineering tests in the context of machine procurement

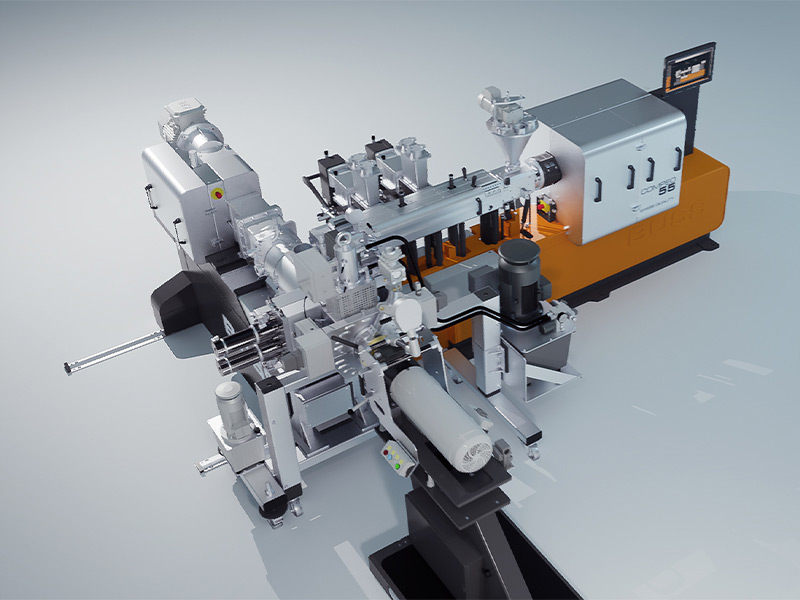

In these situations, BUSS is the partner that can oversee the challenges and develop solutions. Our proven BUSS Kneader technology plays a central role in tackling demanding tasks.

In our test laboratories, experienced engineers verify and optimize the essential machine and plant parameters. And BUSS can thus provide its customers with the assurance of how their plant can be successfully designed and sustainably operated. Our long-standing and in-depth expertise in many applications makes us a valued sparring partner for demanding material applications.

BUSS Process Technologyfor numerous compounding processes

One compounder, over 30 manufacturable types of plastics.

BUSS offers comprehensive know-how for the entire compounding process. Our extensive network of partners ensures customized plant concepts. This includes our own technologies for peripheral components, well-thought-out plant engineering concepts, and well-founded process engineering expertise. From material feeding to pelletizing and beyond, our engineers provide you with the most suitable solutions.

Discover the process-engineering versatile possibilities of our compounding technology.

BUSS Technika

The Technikum - a special add-on for all customers!

Our Technika in the main markets support feasibility testing and the precise definition of technical execution. With optimal system design and customized plant configuration, we minimize risks and create decisive competitive advantages. As an experienced partner, we accompany our customers from the first idea to realization, ensuring tailored and future-proof solutions.

The work in our test laboratories

What does BUSS do in the Technikum? How do projects proceed?

Before the actual tests are conducted in one of our laboratories, a series of preparatory steps is required. The materials must be precisely defined, and the application and test objectives must be clearly described. Our specialists then address technical and organizational challenges.

- Pre-selection of the optimal machine configuration

- In a preliminary test, all plant components are checked before the trials begin with the customer

- Trials with various machine parameters and shaft configurations are conducted to best meet or exceed the specifications

- Optimization of feeding and dosing

- Prediction for scaling to production conditions

- Further investigations provide clear guidelines for the correct dimensioning of the plant, such as motor, dosing, pelletizing, heating capacity

- In the analysis laboratory, test samples are produced and analyzed during the tests

These tasks in the Technikum are usually carried out in close cooperation with the customers. This allows critical parameters of the process or plant to be proactively determined and solutions implemented accordingly.

Our process engineering expertise also results in our broad plant and system competence, with which we comprehensively support our customers.

Why Technikum?

In the video, our CEO Dr. Philip Nising summarizes the advantages and possibilities of our network of test laboratories around the world. He also explains where the process engineering strengths of the BUSS Co-Kneader technology lie. With our unique kneading principle, interesting and forward-looking possibilities open up for our customers.

Core AdvantagesRely on our process engineering expertise