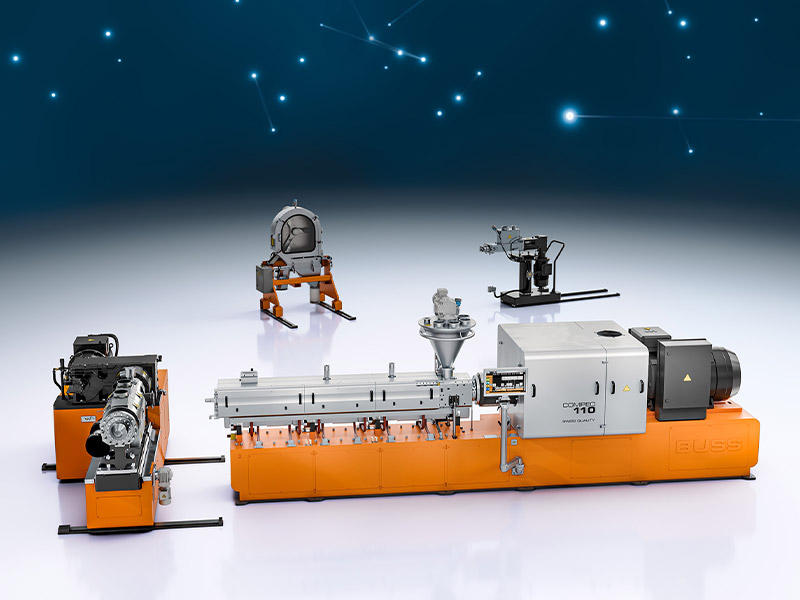

Precise control, long service life, and seamless integration of peripheral equipment make the BUSS compounding technology the first choice for demanding compounds and consistently high production quality. The following components and units are part of the BUSS process technology offering:

CIS Inlet Screws

Reliability. Stability. Efficiency.

BUSS Inlet Screw CIS – Efficient material feeding for maximum process reliability

BUSS COMPEO Inlet Screws (CIS) ensure the uniform and reliable transfer of a wide variety of bulk materials – from powders and granulates to challenging mixtures – directly into the compounder.

Their modular design, simple handling, and virtually maintenance-free operation make them particularly user-friendly. High-quality materials with specialized wear-resistant coatings ensure long service life even under challenging conditions. For additional process and personnel safety, the feed screw is equipped with integrated sensors; cooling for temperature-sensitive materials can be added as an option. The CIS can be flexibly integrated into BUSS compounders as well as other compounding lines and, with six sizes, cover a throughput range from approx. 50 to 7,000 kg/h.

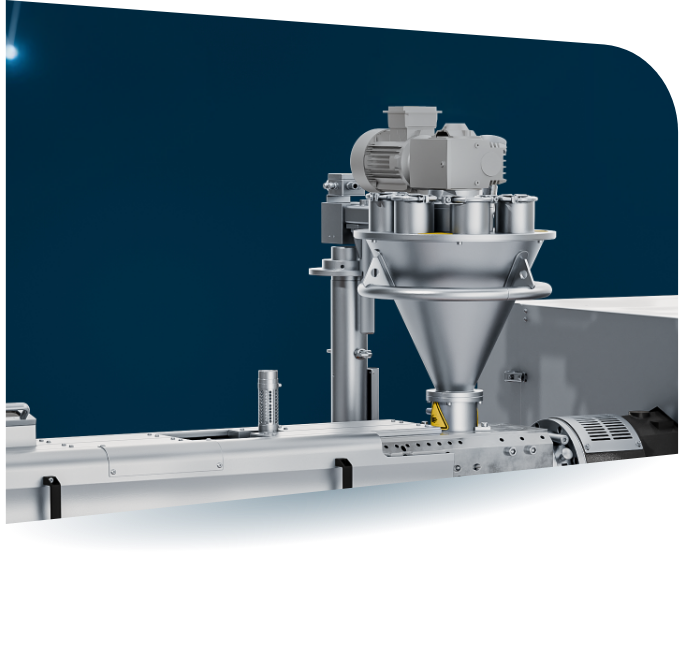

CSF Side Feeder

Continuity. Performance. Versatility.

BUSS Side Feeder CSF – Feeding for high filler loadings and challenging bulk materials

The COMPEO Side Feeder (CSF) by BUSS reliably feeds solids into the side feed zones of the compounder. Even slightly fluidizing powders or high filler contents are fed in safely – material conveyance remains stable and the degree of fill is constant. The combination of twin screw forced feeding and back-venting minimizes air entrapment and dust emissions. The modular, maintenance-friendly design with high-quality, wear-resistant materials ensures high availability with low service requirements. Integrated sensors increase process and operator safety. The integrated cooling system enables the safe feeding of temperature-sensitive bulk materials.

The CSF can be seamlessly integrated into BUSS Compounders as well as other compounding lines via adaptable interfaces and, with six sizes (depending on the material to be conveyed), covers a throughput range of approx. 50 to 10,000 kg/h.

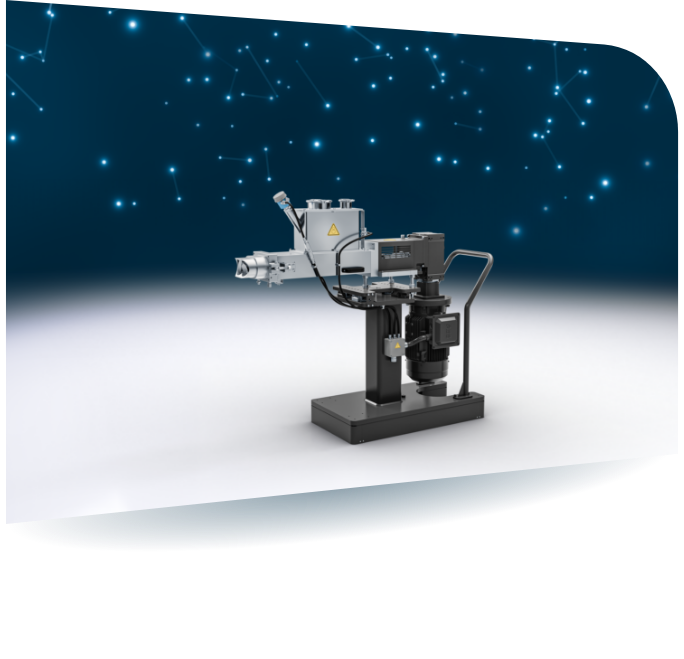

CSS-F Discharge Units

Productivity. Robustness. Usability.

BUSS Single Screw Discharge CSS-F – Precise pressure build-up and reliable product discharge

The CSS-F reliably builds up the pressure required for filtration and pelletizing and ensures constant conditions thanks to its adjustable temperature zones and temperature-controlled screw. Together with integrated degassing, which reliably removes gases and volatile components, the CSS-F thus ensures high compound quality. For service purposes, the CSS-F can be easily disconnected and cleaned thanks to its detachable flange connection and roll-out system.

With its robust design, high-quality materials, and maintenance-friendly construction, the CSS-F offers high availability with minimal effort. Thanks to adaptable interfaces, it can be seamlessly integrated into BUSS as well as other compounding lines. The CSS-F series covers a throughput range of approx. 50 to 7,000 kg/h, making it suitable for a wide range of applications.

CSS-C Discharge Units

Competence. Performance. Reliability.

BUSS Single Screw Discharge CSS-C with connecting tube CCT– PVC-optimized discharge unit with free fall and effective degassing

The CSS-C picks up the material flow from free fall via the CCT connecting tube – ideal for PVC compounds. Gases and volatile components are reliably removed before the single-screw discharge unit gently conveys the material and builds up the pressure required for filtration and pelletizing. Multi-zone temperature control of the barrel and temperature-controlled screw stabilize the product temperature, thus ensuring compound quality.

Direct process visibility via the start-up chute and integrated inspection windows in the CCT enable a convenient start-up process with reduced scrap. The robust, maintenance-friendly design allows for easy access and quick cleaning. Adaptable interfaces allow the CSS-C with CCT to be seamlessly integrated into BUSS as well as other compounding lines – perfect for a wide range of PVC applications. The CSS-C series covers a throughput range from approx. 50 to 13,000 kg/h.

CPS-F Pelletizer

Precision. Flexibility. Performance.

BUSS Pelletizing System CPS-F

BUSS‘ pelletizing technology perfectly meets the needs of cable and performance compounds as well as viscous and porous applications. It combines precision cutting with intelligent flow design, ensuring highly consistent pellet quality and reliable processing.

Developed to fulfill economic, technical and safety standards, the CPS-F stands out with a compact and modular layout, intuitive handling, and easy integration into new or existing compounding lines. Available in various sizes, CPS-F systems cover a wide throughput range from 80 to 3,500 kg/h, making them a perfect match for both high-performance production and flexible compounders.

More about us

Co-Kneader series

Four systems. One principle. The co-kneaders from BUSS stand for efficient, modular compounding solutions. Thanks to patented process technology with the oscillating screw shaft and precise temperature control, each series guarantees the highest product quality with maximum application versatility.