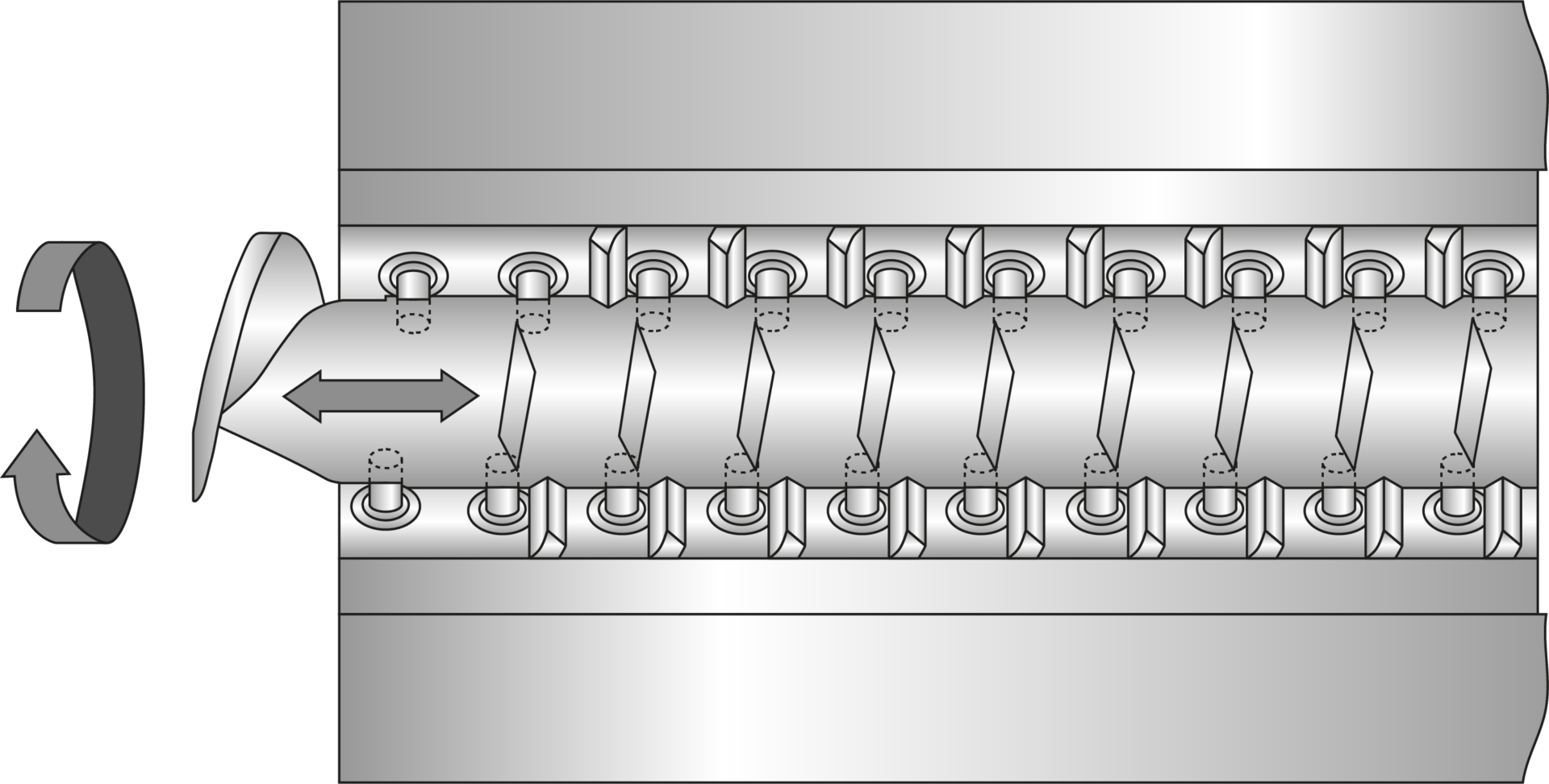

The oscillating screw shaft ensures an intensive product exchange in the axial direction through multiple division, folding, and reorientation of the kneading mass. This results in an excellent distributive mixing effect through optimal distribution of the raw materials. The BUSS Co-Kneader technology is particularly effective when liquid additives need to be incorporated or a high level of fillers must be added. The interaction of the characteristic kneading flights of the screw shaft and the stationary kneading pins achieves effective mixing. The oscillating movement of the screw shaft allows for an extremely short process length.

Our Compounding Technology

The excellent mixing properties of the BUSS Compounders are due to their unique functional principle: simultaneous rotation and axial oscillation of the screw shaft and the stationary kneading pins.

Our long-standing expertise in process engineering enables us to comprehensively advise and support our customers from the feeding of the pellets into the compounder to the further processing of the compound.

Advantages

and Special Features of BUSS Co-Kneader Technology

The unique co-kneader principle

This video shows the operating principle of the oscillating shaft of our BUSS co-kneader in conjunction with the kneading elements and pins. It is a unique compounding system with unparalleled flexibility. This allows for customized compounding conditions for versatile applications. Tailored shaft configurations lead to moderate shear and temperature conditions for sensitive materials. The interaction of the kneading flights of the screw shaft and the kneading pins ensures intensive self-cleaning and distributive material mixing.

BUSS compounder vs. extruderWhere the co-kneader surpasses the extruder

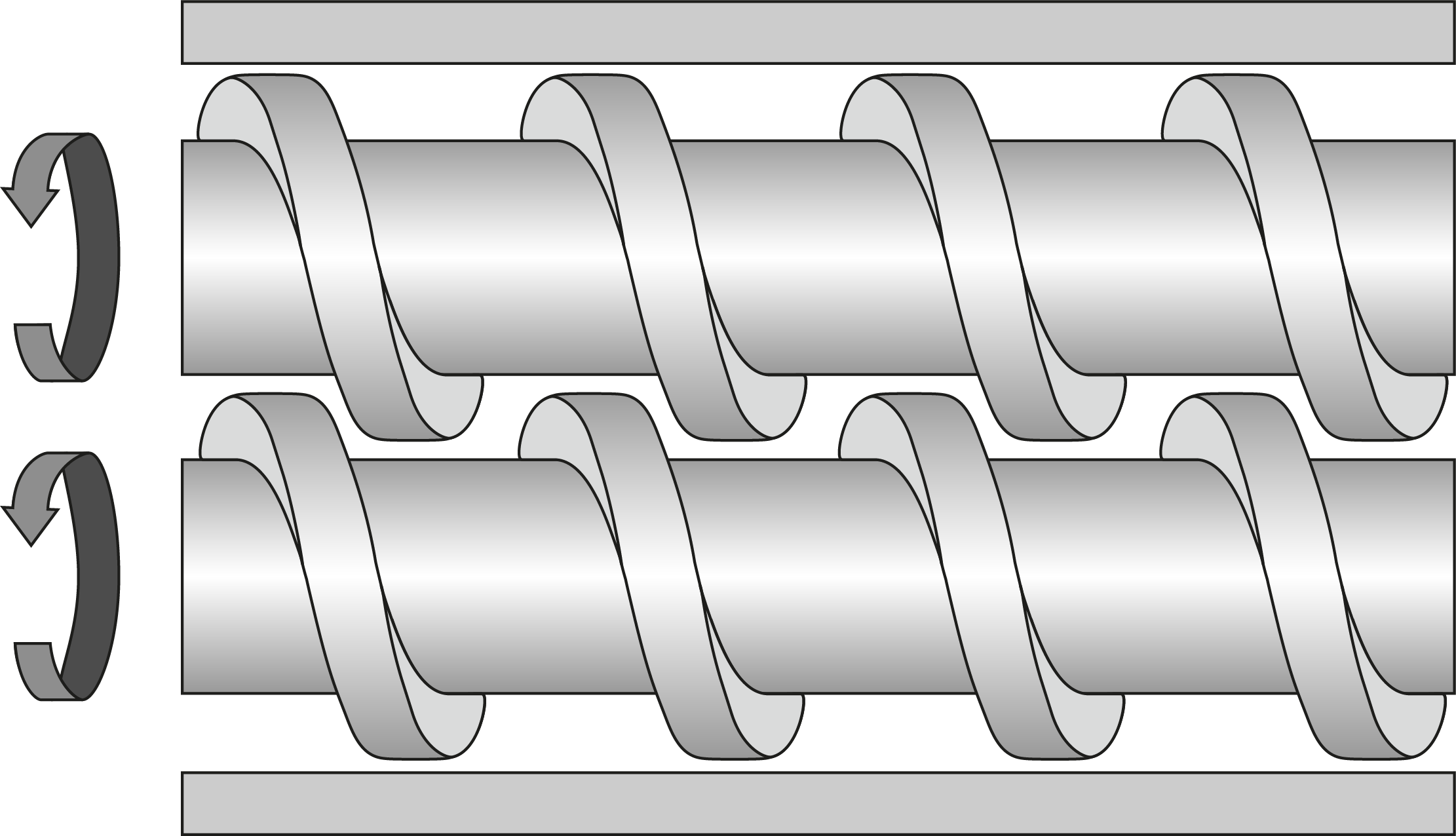

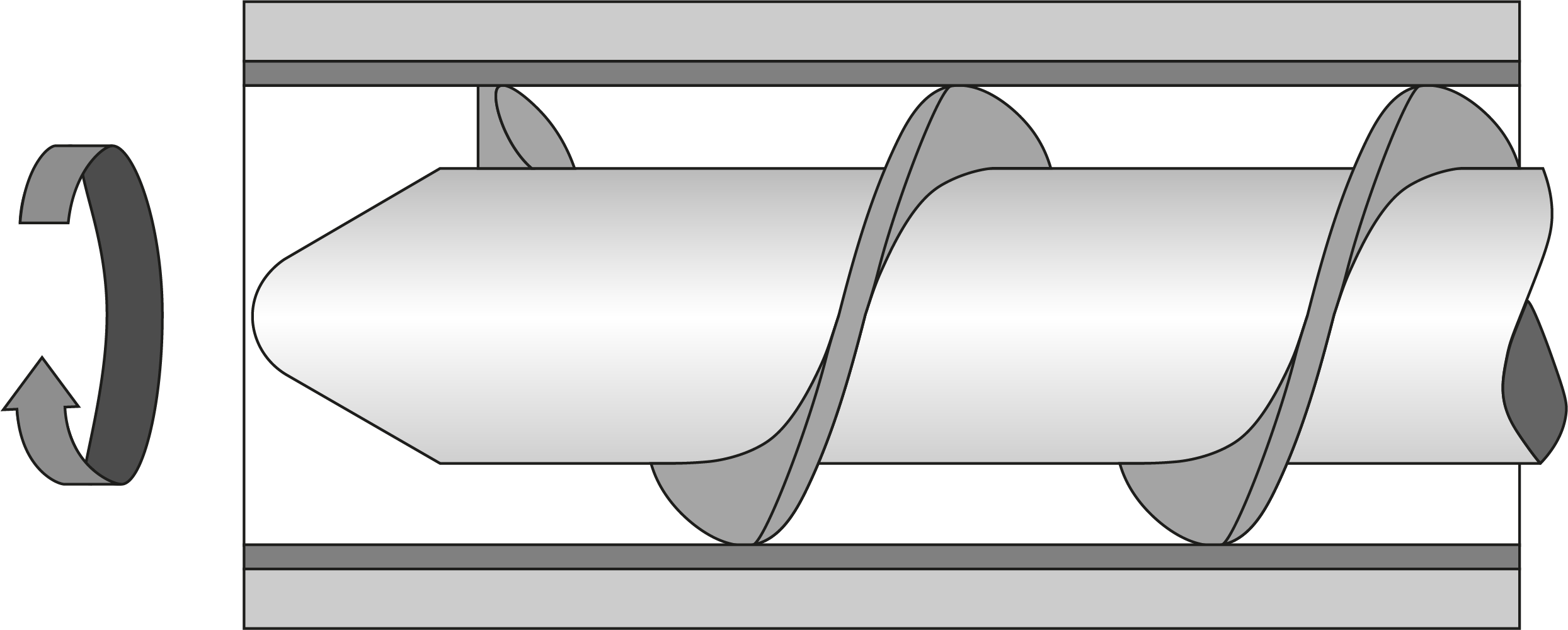

At first glance, the principle of the BUSS Kneader might be mistaken for a conventional extruder. However, it is crucial to understand the differences between the various systems to make the right choice for the required application, as each system has its specific advantages. The following overview shows key features in comparison. Contact us with your requirements!

BUSS Co-Kneader

- Rotation + axial oscillation (1 stroke/revolution)

- Consistent, adjustable shear rates

- Very good process control

- Good self-cleaning effect

- Especially suitable for demanding mixing processes

Twin-screw extruder

- Two co-rotating screws, varying shear gap

- Fluctuating shear rate due to tolerances in the shear gap

- Irregular temperature/material flows with challenging materials

- Good self-cleaning effect

- Limited efficiency with challenging materials

Single-screw extruder

- A rotating screw

- Low shear and temperature buildup

- Hardly controllable mixing process

- No self-cleaning effect

- Only suitable for simple applications

The detailed comparison between BUSS Kneaders and conventional extruders

The COMPEO Compounder in the Context ofComplete Systems

The BUSS Co-Kneaders enable gentle, high-quality processing of materials. With consistent, moderate shear rates that maintain a narrowly defined temperature range and avoid temperature peaks, as well as through intensive, distributive mixing, the production of sophisticated compounds is made possible.

Our BUSS Compounding Technology and these additional technical features lead to the successful use of our BUSS machines in complete systems:

- Pressure Generation, Discharge Units: In the BUSS Co-Kneader, mixing occurs independently of the pressure build-up of the downstream discharge unit. This allows for individual optimization of both process steps – the material can be gently processed at low pressure and lower temperatures.

- Filler Feeding: With the BUSS Compounding Technology, filler contents of up to 90% are possible. To achieve these high filler contents, side feeders with multiple feeding positions and gravimetric dosing devices are used. BUSS side feeders significantly improve the efficiency of feeding compared to other systems.

- Specialized Pelletizing Technology: The proprietary pelletizing technology offers precise control and high efficiency.

- Integration of Proven Modules: Additional modules from established partners complement the BUSS technology, creating a comprehensive solution for complex production requirements.

Through the seamless integration of the BUSS Compounder into upstream and downstream units, a system is created that meets the highest demands for quality and productivity.

Our experienced project team ensures with enthusiasm and responsibility that BUSS Compounding Systems are optimally tailored to the specific application and operate reliably, continuously, and process-optimized.

Process Engineering & Technical Center

BUSS provides extensive expertise for every step in the compounding process. Based on our many years of experience, we develop customized system concepts with innovative process technology and our own technologies. In our laboratories, our engineers focus on optimizing the entire compounding process – from material feeding to pelletizing. With our modular concept, we collaborate with you at the BUSS technical center to develop the ideal process solution, featuring optimally coordinated co-kneaders.