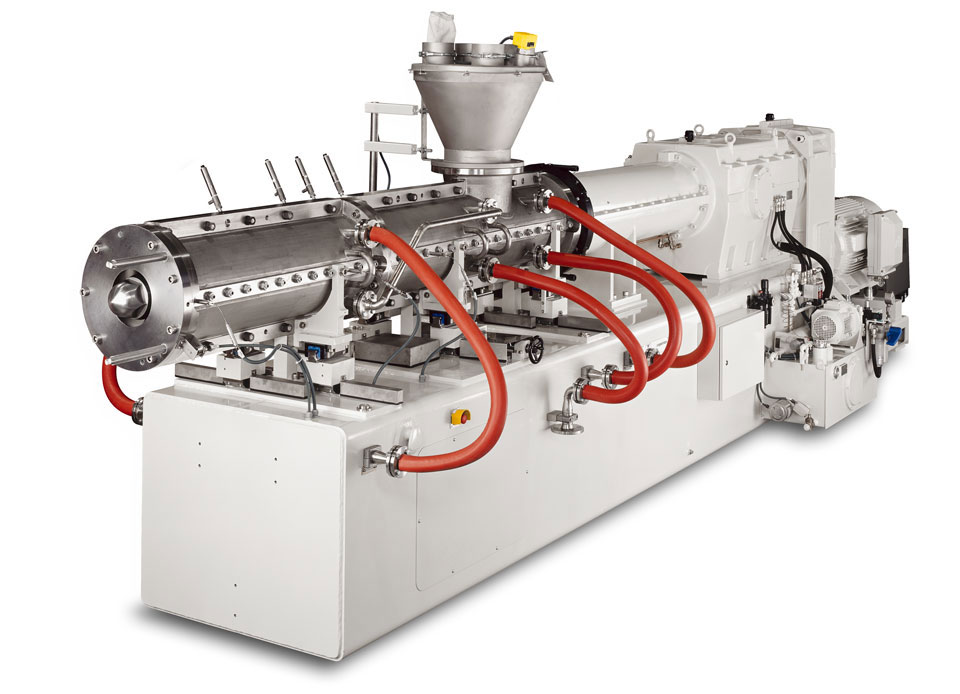

LR Co-Kneader

The specialist for the food industry

BUSS Co-Kneader technology for food processing and manufacturing gum base

The first BUSS Co-Kneader for food processing was delivered to a chocolate manufacturer in 1948. Gentle working, efficient self-cleaning and easy accessibility to the process zones, typical for these machines, have always been indispensable requirements in this field. Due to similar compounding requirements, LR Co-Kneaders are suitable for the food industry and for processing elastomer silicones.

Today, BUSS Co-Kneaders are used in the food industry for compounding chocolate and brittle dough, producing sugar concentrate and soft chews, as well as for the preparation of chewing gum base, chewing gum and bubble gum. BUSS LR Co-Kneaders for the food industry have a larger free volume (Do / Di = 1.81) than those used in the plastics industry, a smaller diameter/stroke ratio (Do / H = 4.0) and a lower shear rate.

Operating principle advantages

The unique operating principle of the BUSS LR Co-Kneader ensures gentle, yet homogeneous processing. In addition, the efficient macro- and micro-mixing results in a narrow residence time distribution and an excellent self-cleaning capacity. Consequently, BUSS LR Co-Kneaders are first choice for shear-sensitive products such as

- Pastries, cakes and biscuits

- Breakfast cereals

- Snack pellets

- Chocolate doughs

- Sugar concentrates

- Soft chews

- Chewing gum, bubble gum and gum base

Impressive processing

of chew mass with the LR Co-Kneader

The LR Co-Kneader’s gentle, yet homogeneous preparation is most clearly impressive during the continuous drawing of chew mass. Sugar mass fed at about 90°C is cooled down to about 40°C and crystallized in the BUSS Co-Kneader, which thus also serves as a heat exchanger for dissipating the crystallization heat. Constant orientation in the shear zone of the BUSS Co-Kneader ensures an extremely fine and uniform crystal structure for optimal chew mass texture and chewing enjoyment.

Technical data

BUSS LR Co-Kneader sizes range from screw diameters of 100 to 400 mm for throughputs of 200 to 7000 kg/h.

Overall length incl. drive assembly | 11 L/D: 3.200 15 L/D: 3.600 19 L/D: 4.000 |

Height [mm] | 1.250 |

Center line height [mm] | 1.000 |

Width [mm] | 1.200 |

Feed port height [mm] | 1.090 |

Weight [kg] | 11 L/D: 1.500 15 L/D: 2.050 19 L/D: 2.600 |

Max. screw speed [rpm] | 300 |

Max. drive rating [kW] | 50 |

Overall length incl. drive assembly | 11 L/D: 7.100 15 L/D: 7.900 19 L/D: 8.700 |

Height [mm] | 1.550 |

Center line height [mm] | 1.095 |

Width [mm] | 1.200 |

Feed port height [mm] | 1.325 |

Weight [kg] | 11 L/D: 3.300 15 L/D: 4.000 19 L/D: 4.500 |

Max. screw speed [rpm] | 250 |

Max. drive rating [kW] | 115 |

Overall length incl. drive assembly | 11 L/D: 9.800 15 L/D: 11.000 19 L/D: 12.200 |

Height [mm] | 1.900 |

Center line height [mm] | 1.450 |

Width [mm] | 1.400 |

Feed port height [mm] | 1.745 |

Weight [kg] | 11 L/D: 10.000 15 L/D: 12.700 19 L/D: 15.000 |

Max. screw speed [rpm] | 150 |

Max. drive rating [kW] | 200 |

Overall length incl. drive assembly [mm] | 11 L/D: Specification depends on requirements 15 L/D: 12.700 19 L/D: Specification depends on requirements |

Height [mm] | 1.500 |

Center line height [mm] | 1.250 |

Width [mm] | 2.200 |

Feed port height [mm] | 1.550 |

Weight [kg] | 11 L/D: Specification depends on requirements 15 L/D: 14.000 19 L/D: Specification depends on requirements |

Max. screw speed [rpm] | 120 |

Max. drive rating [kW] | 280 |