Plastics have been around for over 100 years. Especially in the post-war period, they began their triumphant march around the globe. Today, life without them has become unimaginable. Since 1945, we have supported numerous industries with our patented co-kneader technology as the key to manufacturing the artificial composites that are so important to them.

PlasticsThe hydrocarbon chains that shape our everyday life

Without plastics, our everyday life would be unimaginable. They are versatile, lightweight, robust, and cost-effective. With our BUSS co-kneaders, our customers have been compounding plastics for decades, mostly in the form of pellets for films, consumer goods, or high-performance plastics for technical applications.

Our compounding technology enables the precise preparation and processing of polymers of all kinds, including polyolefins, PVC, engineering plastics, and high-performance polymers. Whether it involves the incorporation of fillers, additives, glass fibers, natural fibers, or colors: BUSS compounding systems guarantee the highest product quality and efficiency.

Thanks to the flexible process control and high mixing performance, BUSS co-kneaders are proven systems worldwide for the plastics compounding industry.

Plastics that can be manufactured with BUSS co-kneaders:

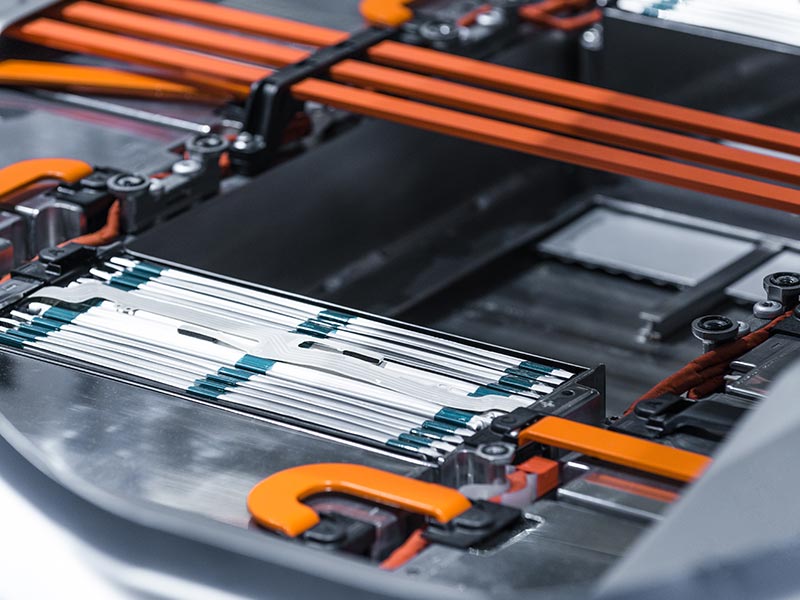

AutomotiveHigh-performance materials for automotive production

Modern vehicle production places high demands on materials: they should be lightweight, durable, safe, and long-lasting. BUSS co-kneaders have been an integral part of the production of such demanding materials for decades.

Our technology is used in the manufacturing of high-quality plastic compounds for interior and body components, seals, cable sheathing, as well as highly stressed components. Our solutions are particularly in demand for processing fiber-reinforced plastics, thermoplastic elastomers, sealants, and electrical insulation materials.

Through gentle processing, uniform distribution of fillers, and precise temperature control, compounds are created that meet both the mechanical and optical requirements of the automotive industry. Our experience in the automotive sector ensures the highest process reliability – from the idea to series production.

Automotive materials that can be produced with BUSS co-kneaders:

Rubber ProductsMaterials between elastic and rigid

In the tire and rubber industry, materials must be versatile, highly durable, and yet flexible. This is where BUSS Co-Kneaders come into play: Our technology enables the precise processing of Rubber Compounds needed for tires, seals, hoses, damping elements, and many other applications.

Through gentle processing, effective mixing, and optimal temperature control, high product quality is achieved. Especially when incorporating fillers such as carbon black, chalk, or oils, the process proves itself, as uniform distribution is ensured while maintaining low shear forces.

This results in compounds that impress with their resilience, elasticity, and longevity – precisely tailored to the high demands of rubber and tire production.

Rubber Compounds that can be produced with BUSS Co-Kneaders:

AluminiumCarbon Paste for Aluminium Electrolysis

Without carbon paste, there is no aluminium. And without aluminium, our modern world would be hard to imagine. Whether in cars, airplanes, buildings, power lines, or packaging: aluminium is lightweight, robust, and versatile. A key material for mobility, energy supply, and everyday life.

Aluminium is produced in an electrolysis process that uses special anodes. For decades, BUSS compounders have been regarded as a proven technology for anode paste manufacturing. They mix petroleum coke, liquid pitch, and other components particularly homogeneously and at precisely controlled temperatures to create carbon paste with optimal properties.

The result: High-quality carbon pastes that ensure maximum efficiency in aluminium production. BUSS is one of the leading partners worldwide in this essential process.

Details about our expertise in Carbon Paste manufacturing:

Construction industryPlastics in the construction industry

Modern buildings would be hardly imaginable without innovative plastics. Window profiles, pipes, floor coverings, or seals. Highly specialized plastic compounds are used everywhere today. They ensure energy efficiency, lightweight construction, aesthetics, and safety in the building sector.

Especially in the manufacturing of such construction products, precisely tuned compounding processes are crucial. BUSS co-kneaders impress here with their unique kneading principle: They enable homogeneous material distribution, gentle melting, and highly filled plastics. All essential factors to ensure the highest product quality.

Plastics manufactured with BUSS co-kneaders are used for:

Medical technology and cosmetics industryPlastics in highly regulated application areas

In medicine and cosmetics, safety, purity, and absolute process reliability are paramount. Whether for implants, syringes, catheters, or packaging for creams and care products, the compounds used must comply with strict legal requirements while also providing the highest and most consistent functionality.

BUSS co-kneaders ensure exactly this process reliability. Thanks to their excellent temperature control and particularly gentle processing, even sensitive additives and fillers remain stable. At the same time, the modular plant design allows for precise adaptation to a wide range of formulations for the production of flexible materials to high-strength materials.

With our experience in the demanding processing of plastics, we support manufacturers in efficiently and reliably producing innovative products for health and care.

Plastics manufactured with BUSS co-kneaders are used for:

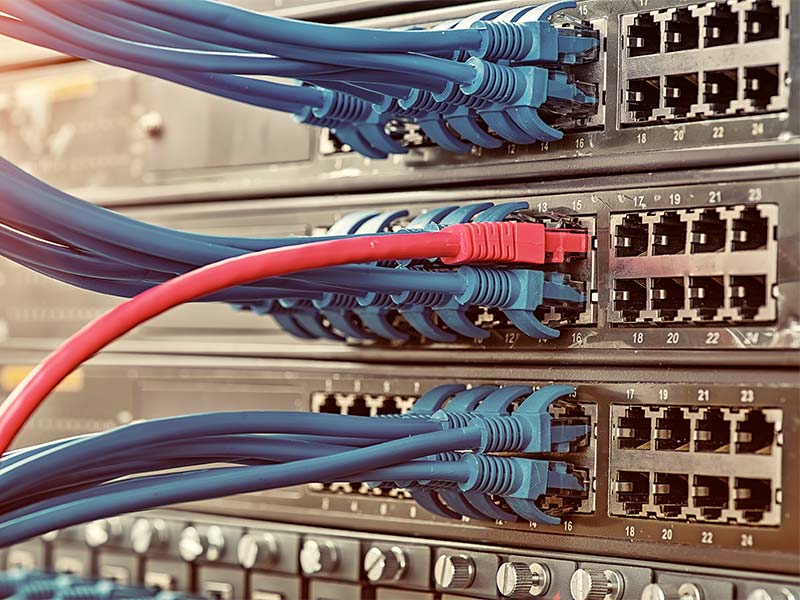

Energy industryWithout electricity, our world would not be the same.

A reliable energy supply forms the foundation of modern society. From simple charging cables to offshore wind farms, cables ensure that electricity is transported safely and efficiently everywhere. However, these cables place the highest demands on their materials: insulation materials must withstand extreme voltages, weather influences, and aging processes.

BUSS co-kneaders have been used for decades in the cable industry for insulation and semiconductive layers as well as for specialty compounds, for example, for high and extra-high voltage cables. Our co-kneader technology enables particularly uniform, precisely dosed, dispersive mixing with a narrow temperature process window and without degradation of the materials. The result: maximum safety, efficiency, and durability – even at voltages of 600,000 volts and more.

Whether for power cables, data lines, or specialty applications: BUSS offers tailored solutions for the compounds of the energy sector.

Plastics manufactured with BUSS co-kneaders are used for:

Food industryCompounded products for our taste experiences

What sounds unusual at first glance is already well established: Compounders are also used in the food industry. Whether in the production of gum base, chewy candies, chocolate products, crackers, or certain baked goods… Wherever precise and uniform mixing and crystallization processes are required, co-kneaders demonstrate their strengths.

The great BUSS advantage: Our co-kneaders enable particularly gentle kneading and mixing without overheating or loss of quality of the ingredients. With the machines’ cooling capabilities, even crystallization processes can be realized. At the same time, formulations can be flexibly adjusted to produce various product variants.

Our expertise ensures the highest product quality, reproducible results, and process reliability in production. In close collaboration with our customers, delicious products are created that are consumed daily in countless varieties around the world.

BUSS Co-Kneaders are used for:

More about us

Co-Kneader series

Four systems. One principle. The co-kneaders from BUSS stand for efficient, modular compounding solutions. Thanks to patented process technology with the oscillating screw shaft and precise temperature control, each series guarantees the highest product quality with maximum application versatility.

Career

Looking for a new challenge? In an industrial company that combines tradition and Swiss values with innovation and internationality? We create excellent products with both large and small brands. And it’s never boring. With us, you work in a future-oriented environment. At BUSS, a profession can become a calling. And we thrive on your passion for innovation, responsibility, and customer satisfaction.