COMPEO

Pioneering compounding technology

Compounding systems for demanding materials. Amazingly flexible.

The innovation and profit potential of the polymer industry lie in the production of extremely high-quality compounds. The end products should be reinforced, scratch-resistant, flame-retardant, weather-resistant, and at the same time resource-saving. This requires a compounder that can effortlessly and thoroughly mix significant amounts of additives.

We have your solution: COMPEO, the state-of-the-art compounder that offers more versatility in its application, higher flexibility in process engineering, and increased added value in compound manufacturing.

Proven innovation,

made for the future!

The best

from past co-kneader series combined!

COMPEO

in motion

“Amazingly flexible.” This is the promise of our COMPEO compounders for the polymer and plastics industry. COMPEO is the state-of-the-art compounder from BUSS. It offers more versatile application possibilities, more flexibility in process technology, and greater added value in compound manufacturing. Discover all the details in motion here.

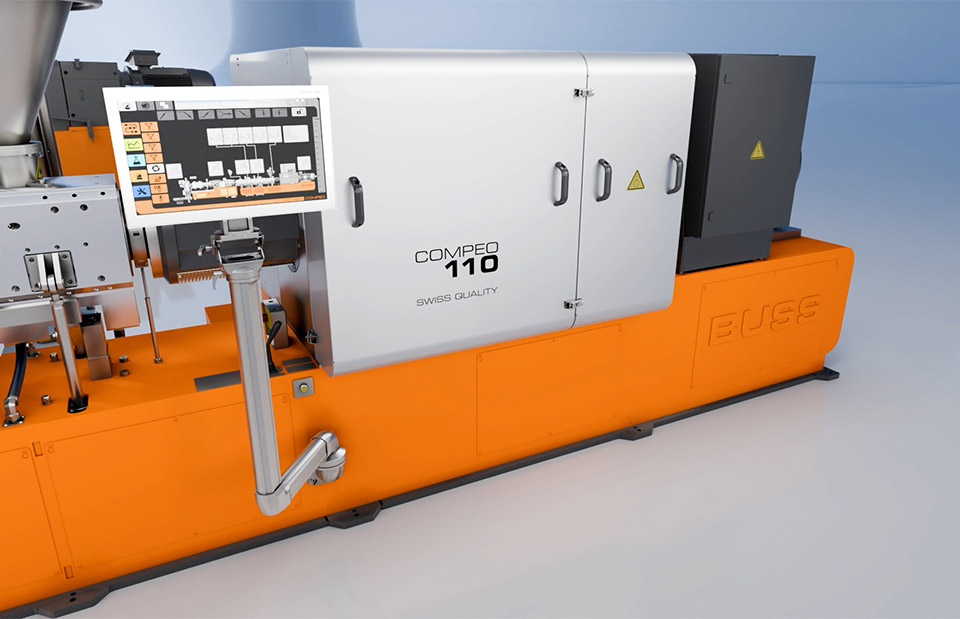

BUSS Process Technology: COMPEO 110

Typical plant layouts for material preparation

Working principle of the kneading process

COMPEO – Latest compounder generation from BUSS

Configurable process zone

Features & Benefits

Unique features of our COMPEO Compounding System

With its unique functions, the COMPEO Compounding System offers compelling advantages for an extremely diverse range of applications in the field of plastic compounding:

Incredibly flexible, incredibly different.

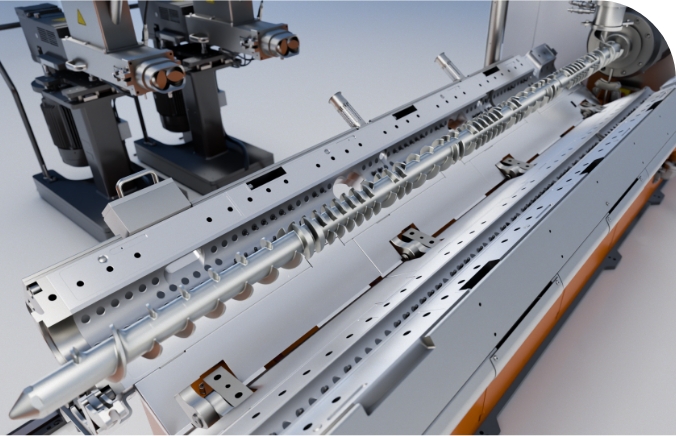

The configurable process space of the COMPEO Compounder opens up entirely new process engineering possibilities through the use of mixing and kneading elements with two to four rows of flights. The combination of conventional three- and four-flight elements with newly developed mixing elements allows, on one hand, the achievement of previously conflicting goals, such as high specific throughput with controllable energy input. On the other hand, the COMPEO process window is significantly larger than in previous series. The throughput can be varied in a ratio of 1:6, which increases both system flexibility and user-friendliness. The high throughput ratio is particularly advantageous during startup, for small batches, and in inline processes when the downstream unit requires consistent product quality even with highly variable throughput rates.

The unbeatable COMPEO advantages

Our compounder series enables incomparably uniform, moderate shear rates. This makes processing shear-sensitive compounds almost child’s play. The highly precise temperature control through the shaft-internal heating element and the numerous temperature sensors ensure constant temperature zones in the process area. The unique screw geometry allows high filling levels for more throughput. And the liquid injection, which can be placed at any bolt position, enables even more precise liquid addition in the compounding process.

COMPEO

unique geometries for more flexibility!

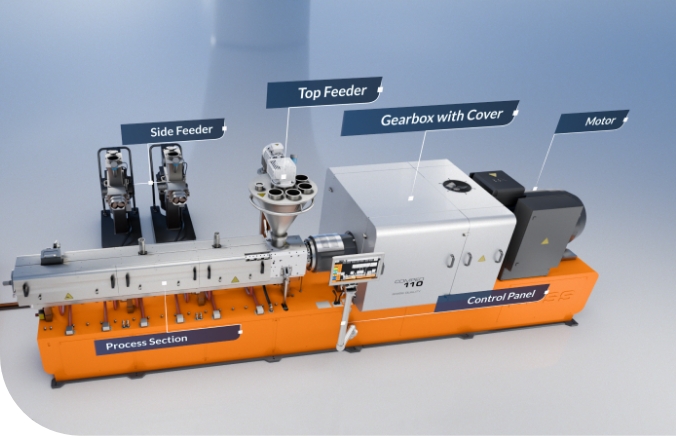

The innovative operating principle of the COMPEO compounder series

In the basic version with two inlet zones, polymers, additives, and some of the fillers are fed through the first intake opening. In the melting zone, the polymers are melted and mixed with the additives. In the second and third feed zones, additional fillers are fed via a side feeder and homogeneously distributed in the subsequent mixing zone. Amazingly flexible. Amazingly different. Volatile substances and air inclusions are expelled in the degassing zone before the product is passed on to the discharge unit. Process length, type and number of feeding units, temperature, degassing, and process geometries are defined according to the respective plastic compounding application.

Unparalleled process geometries expand the process window

The screw geometries of the COMPEO series ensure a high throughput at up to 20% lower speeds. By increasing the volumetric torque by 15%, the configuration of longer mixing zones is enabled. The result is more stable process conditions without additional energy input. All kneading flights are designed as free-form surfaces, ensuring uniformly intensive shearing of the product and thus eliminating local overheating.

The configurable process zone of the COMPEO compounding system opens up completely new process engineering possibilities through the use of mixing and kneading elements with two to four rows of flights. By combining conventional kneading elements with specifically developed mixing elements, previously conflicting goals can be achieved, such as high specific throughput with controllable energy input. On the other hand, the process window of the COMPEO is significantly larger than that of previous series. This allows the throughput to be varied in a ratio of 1:6. This increases both the system flexibility and user-friendliness. The high throughput ratio is particularly advantageous during startup, for small batches, and in inline processes where the downstream unit requires consistent product quality, even with highly variable throughput rates.

Stronger together

Peripheral units enable the work of the COMPEO.

The configurable process zone of the COMPEO compounding system is only as strong as the peripheral units that bring the material into the process room and the subsequent discharge unit that prepares the polymer mixture for further processing.

Precisely fitting inlet screws in different throughput versions, as well as perfectly adjustable side feeders for introducing, for example, additives, ensure application-specific ideal fill levels in the process room.

The BUSS’ discharge units, available in various designs, are a perfectly matched complement to the COMPEO. Details on the different designs are presented within the scope of process technology.

Typical system configurations

for a wide range of applications.

Experience the versatility of our COMPEO Compounder

The COMPEO compounder series offers a variety of applications and the highest flexibility in processing materials for the infrastructure, transportation, consumer goods, construction, food, and energy markets. In our COMPEO showroom, we showcase typical system layouts for some of the many material and composite systems that benefit from manufacturing with BUSS technology. Dive into the world of COMPEO! See what is possible with the unparalleled compounder generation.

Service-oriented Concept

The BUSS service team is available worldwide to provide professional support for your compounding system. From project engineering through process-related consulting, installation, and commissioning to training and unparalleled service, we are your partner to secure your investment in the long term. This also includes later retrofitting or overhauling of the systems, relocating the systems, or modernizing the compounding systems.

COMPEO

System Control 4.0

Intuitive operation of the control console, connectivity for Industry 4.0

The system control equipped with a touchscreen is based on the latest controller (Siemens or Allen Bradley) and features an OPC-UA interface for integration into higher-level IT architectures. This interface makes the system fully Industry 4.0 compatible. The modular software is structured according to the system configuration and can be operated intuitively.

Thanks to a recipe management integrated into the system control, switching between recipes can be done practically at the push of a button. All essential system parameters such as fill levels, flow rates or quantities, temperatures, and output are visualized, recorded, and archived. Additionally, defined process parameters such as temperatures, power consumption, or specific energy input – and thus the efficiency of the system – can be continuously monitored with the system control. Optionally, the system can also be maintained via remote diagnostics and remote maintenance.

One design

different sizes!

The COMPEO series offers the right compounder for a wide range of applications and throughput areas. From the smallest compounding machinery for laboratory and testing tasks to the nearly 10-meter-long compounder with up to 13,200 kg/h throughput. The construction from standardized modules allows for cost-efficient configuration of specifically optimized compounding lines for a broad spectrum of demanding processing tasks.

Technical Data

BUSS Compounder | |

Screw diameter [mm] | 45,5 |

Process length [L/D] | 25 |

Screw speed max. [rpm] | 600 |

Drive power [kW] | 27,5 |

Discharge units | |

Screw diameter [mm] | 70 |

Process length [L/D] | 6 |

Drive power [kW] | 5,5 |

BUSS Compounder | |

Screw diameter [mm] | 55 |

Process length [L/D] | 14 … 25 |

Screw speed max. [rpm] | 600 |

Drive power [kW] | 55 |

Discharge units | |

Screw diameter [mm] | 110 |

Process length [L/D] | 6 |

Drive power [kW] | 15 |

BUSS Compounder | |

Screw diameter [mm] | 88 |

Process length [L/D] | 14 … 25 |

Screw speed max. [rpm] | 600 |

Drive power [kW] | 200 |

Discharge units | |

Screw diameter [mm] | 160 |

Process length [L/D] | 6 |

Drive power [kW] | 45 |

BUSS Compounder | |

Screw diameter [mm] | 110 |

Process length [L/D] | 14 … 25 |

Screw speed max. [rpm] | 600 |

Drive power [kW] | 400 |

Discharge units | |

Screw diameter [mm] | 200 |

Process length [L/D] | 6 |

Drive power [kW] | 75 |

BUSS Compounder | |

Screw diameter [mm] | 137,5 |

Process length [L/D] | 14 … 25 |

Screw speed max. [rpm] | 600 |

Drive power [kW] | 800 |

Discharge units | |

Screw diameter [mm] | 250 |

Process length [L/D] | 6 |

Drive power [kW] | 160 |

BUSS Compounder | |

Screw diameter [mm] | 176 |

Process length [L/D] | 14 … 25 |

Screw speed max. [rpm] | 600 |

Drive power [kW] | 1650 |

Discharge units | |

Screw diameter [mm] | 300 |

Process length [L/D] | 6 |

Drive power [kW] | 500 |