Buss Co-Kneader seriesDiversity for every requirement of plastics production

Whether high-performance compounds, sensitive specialty materials, or small quantities in development – with the co-kneader series from BUSS, you will find the right solution for every application.

For 80 years, BUSS has stood for innovative compounders with maximum process reliability, modular adaptability, and excellent compounding quality. Our four series cover a wide range of applications – from large-scale production to laboratory trials. Get to know the differences and discover which co-kneader fits your process.

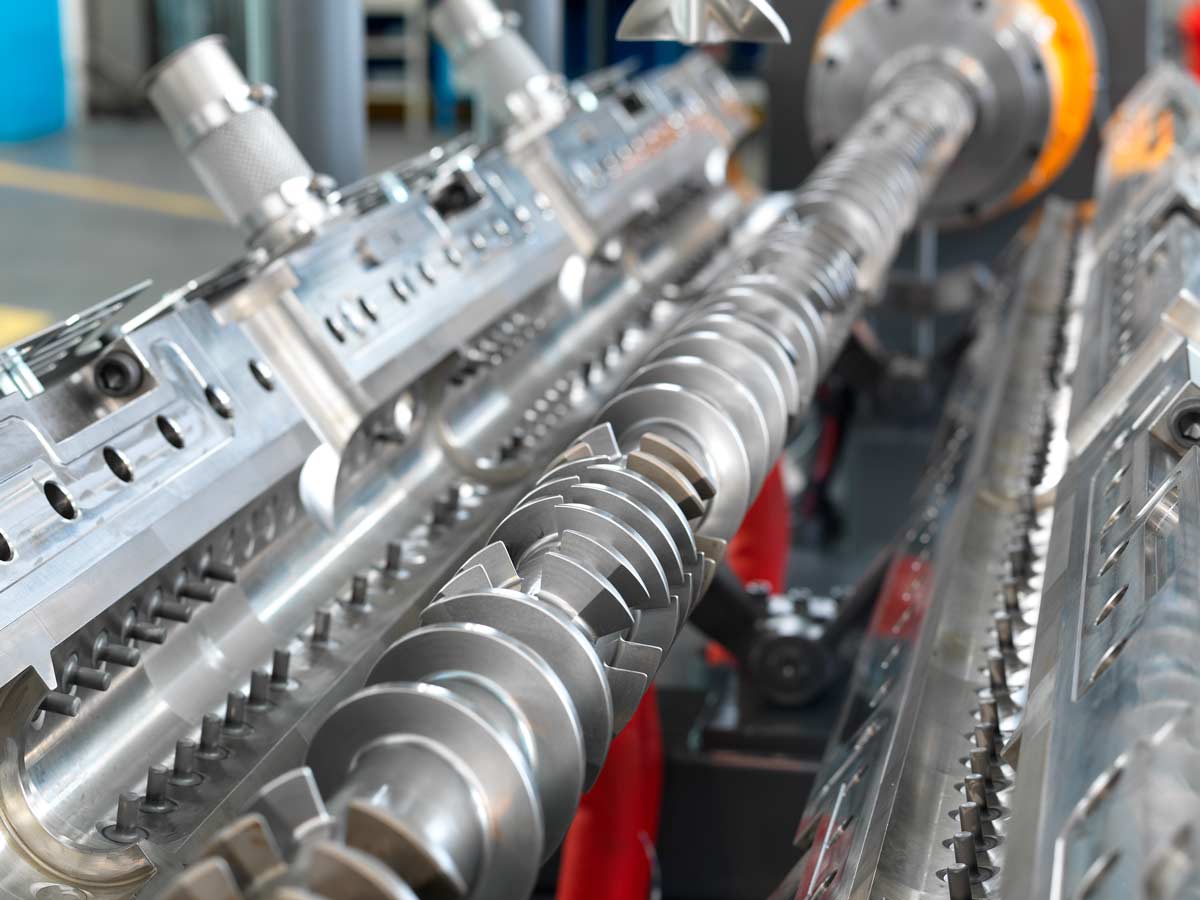

The centerpiece of all BUSS systems is the patented co-kneader technology: a rotating screw shaft with axial oscillation. In combination with precisely controllable temperature management, it enables short process lengths, excellent dispersion, and consistently high product quality – with maximum flexibility.

The Co-Kneader principle

Choose the appropriateBUSS Co-Kneader

One co-kneader principle, four series.Many applications

The co-kneaders from BUSS are designed for maximum material diversity. Whether highly filled, sensitive, abrasive, or viscous – with the right system, you can process a wide range of formulations safely, reproducibly, and in the best quality.

Typical Applications

- Thermoplastics & Elastomers

- Battery compounds & Anode compounds

- Powder coatings

- Thermosets & EMC

- Food technology

- Specialty compounds

- Customer-specific formulations developed in the BUSS technical center

More about us

Career

Looking for a new challenge? In an industrial company that combines tradition and Swiss values with innovation and internationality? We create excellent products with both large and small brands. And it’s never boring. With us, you work in a future-oriented environment. At BUSS, a profession can become a calling. And we thrive on your passion for innovation, responsibility, and customer satisfaction.