Composites are used where high performance requirements are demanded. They are employed in most industries in ever-growing application areas. To meet market demands, customers must be able to follow technological trends in their respective applications, operate economically and sustainably. Competent and reliable partners and systems are crucial for this. The innovative BUSS Co-Kneader Technology comes into play where conventional compounding systems reach their limits, regardless of whether the material is in the form of pellets, powder, liquid, bales, flakes, or any other form.

Our Technological StrengthsBUSS Compounding Advantages

The many polymeric and other raw materials that require compounding present individual challenges for each process. The BUSS Kneader represents a specialized compounding system that offers flexible solutions for these challenges.

Find your application

Anode Paste

For the industrial manufacturing of aluminum, which is considered the most important metal with no iron content, so-called anode paste is of central importance.

Bioplastic materials

Bioplastics have already existed for a very long time. The first industrially produced plastics were cellulose-based and produced industrially as of 1869 and casein, which was produced in large quantities at the beginning of the 20th century as so-called synthetic horn.

PBT / PET compounds

The polymers PET and PBT belong to the polyester family. PET can both exist as amorphous molding material (PET A) and as partially crystalline material (PET C).

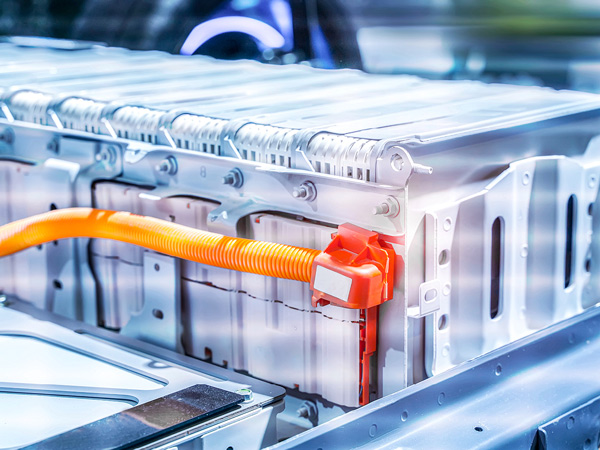

Battery Electrodes

The development and realization of rechargeable battery and battery systems with high energy density are important parts of the response to global trends as well as the UNO sustainability targets.

FRTP fillers

The integration of fillers into a plastic matrix follows two basic targets: improved specific material properties of the compound, for example here breathable foils or films or sound-absorbing tubes and cost savings.

Antistatic compounds

The effect known as triboelectric charging, for which a single contact suffices to charge the surface electrostatically, has the consequence that components often come out of the shaping machine statically charged.

Sioplas

By crosslinking the polyethylene (PEX stands for cross-linked PE), a thermoplastic material can be converted into a thermoset material. This can be used at considerably higher operating temperatures, has better mechanical properties, is more stable against organic fluids and often allows thinner wall thicknesses.

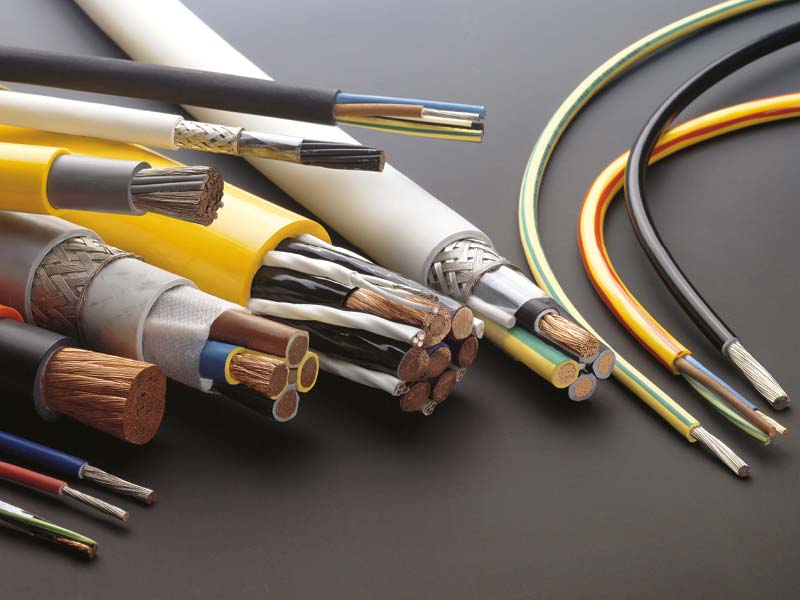

PVC cable compounds

Depending on the requirements profile, different plastics are used for manufacturing cable insulation with BUSS compounding systems. These include polyolefins, TPE, PPE, EEFE, PVA and naturally flexible PVC cable compounds.

Polyisobutylene

The plastic polyisobutylene (PIB) belongs to the olefin polymer family. It has been manufactured industrially since the 1930s and is produced within a wide viscosity range from oil-like to raw rubber-like masses.

Epoxy resin molding compounds

Epoxy molding compounds have been known for their good electrical and mechanical properties as well as their excellent chemical and aging resistance for a long time.

Rubber compounds

Excavations in Guatemala have shown that already in the 3rd century, the Maya knew rubber as a material. Since the 18th century, more and more applications have been described.

Calender feeding

Calender feeding is a system with several heated and polished chill-casting or steel rollers between which the melt, a pre-plasticized molding material from a BUSS Kneader or other materials are fed.

Luxury Vinyl Tiles

In order to achieve these specific LVT properties, the floor covering is composed of several special layers. This is done classically by separate manufacturing of the compounds using BUSS Kneaders and corresponding calendering processes. The respective layers are compacted in the following process.

More about us

Co-Kneader series

Four systems. One principle. The co-kneaders from BUSS stand for efficient, modular compounding solutions. Thanks to patented process technology with the oscillating screw shaft and precise temperature control, each series guarantees the highest product quality with maximum application versatility.