The thermoset materials group, also referred to as duromers, is a group of plastics which can no longer be deformed after hardening. It is one of the three groups according to which polymers can be categorised:

This is distinguished dependent on the extent of macromolecule chain crosslinking in thermoplastics, elastomers or just thermosets. Whereas the thermoplastics have no crosslinking points and are therefore fusible, elastomers and thermosets cannot be fused due to their crosslinking and decompose after exceeding the decomposition temperature (pyrolysis). The thermoset Bakelite, a phenoplastic, is recognised as the first industrially produced plastic at the beginning of the 20th century.

Typical areas of application

Thermosets are hard, glass-like polymer materials which are permanently cross-linked three-dimensionally via chemical primary valence bonding. The cross-linkage takes place when mixing pre-products with branch points and is either activated at room temperature chemically using catalysers or thermally at high temperatures.

The high crosslinking density poses high requirements of the compounding technology for heat-hardening plastic. It is responsible for the very high thermo-mechanical rigidity, excellent electrical properties and the exceptional chemical resistance.

The respective fields of use for the compounding technology are defined from these property profiles. Thus, for example the high-performance thermosets in the car industry for technical parts in the engine compartment or the drive sections are used where their temperature resistance under considerable load is particularly valued.

In electrotechnology, the combination of insulation properties, the advantageous fire behavior and dimensional stability are the reasons for their use. Good resistance to various substances and liquids make thermosets a valued choice for both food- and chemicals applications.

Benefits

BUSS compounding systems offer the following specific benefits

Compounding requirementsfor thermosets

The preparation step for thermosets takes place using polymer pre-products, glass or carbon reinforcement fibers, fillers or also natural fibers. In several cases, the corresponding reaction systems for final thermosetting are also used.

In addition to the gentle integration of the additives, adherence to the absolute temperature limit below the final conductive temperature is the central requirement. This succeeds with BUSS compounding technology and in particular with the BUSS Co-Kneader due to its working principle during which a relaxation sequence follows each gentle shear cycle in an excellent manner. Optimum process temperatures can be proven at all times due to exact measurement of the product temperature via drilled kneading pins.

Customized material solutions are responsible for an economical service life. The economical throughputs and all the advantages of continuous production means such as extremely constant and trackable product quality, a high utilization degree and availability of the systems round off the excellent suitability of BUSS Co-Kneader technology.

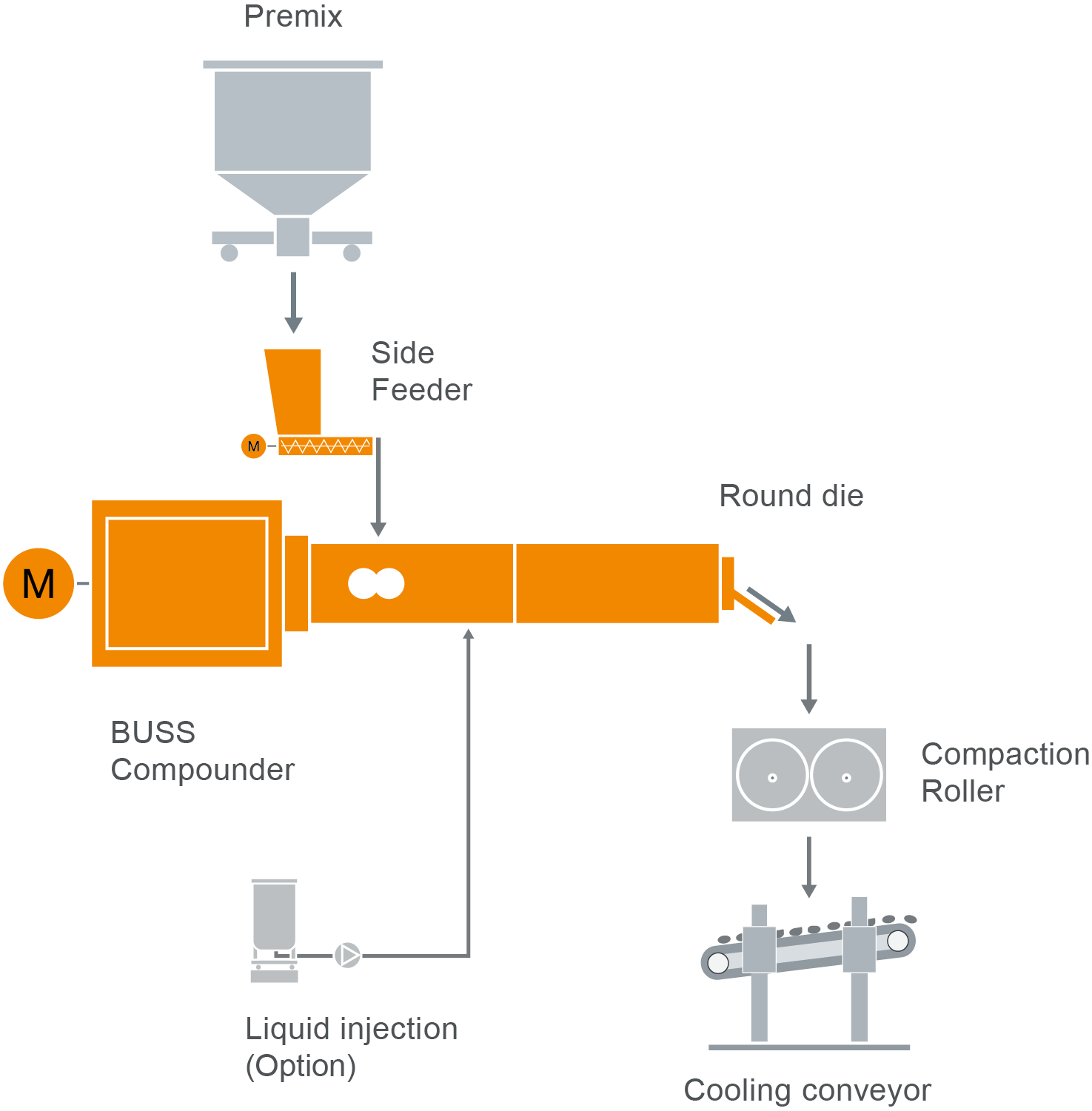

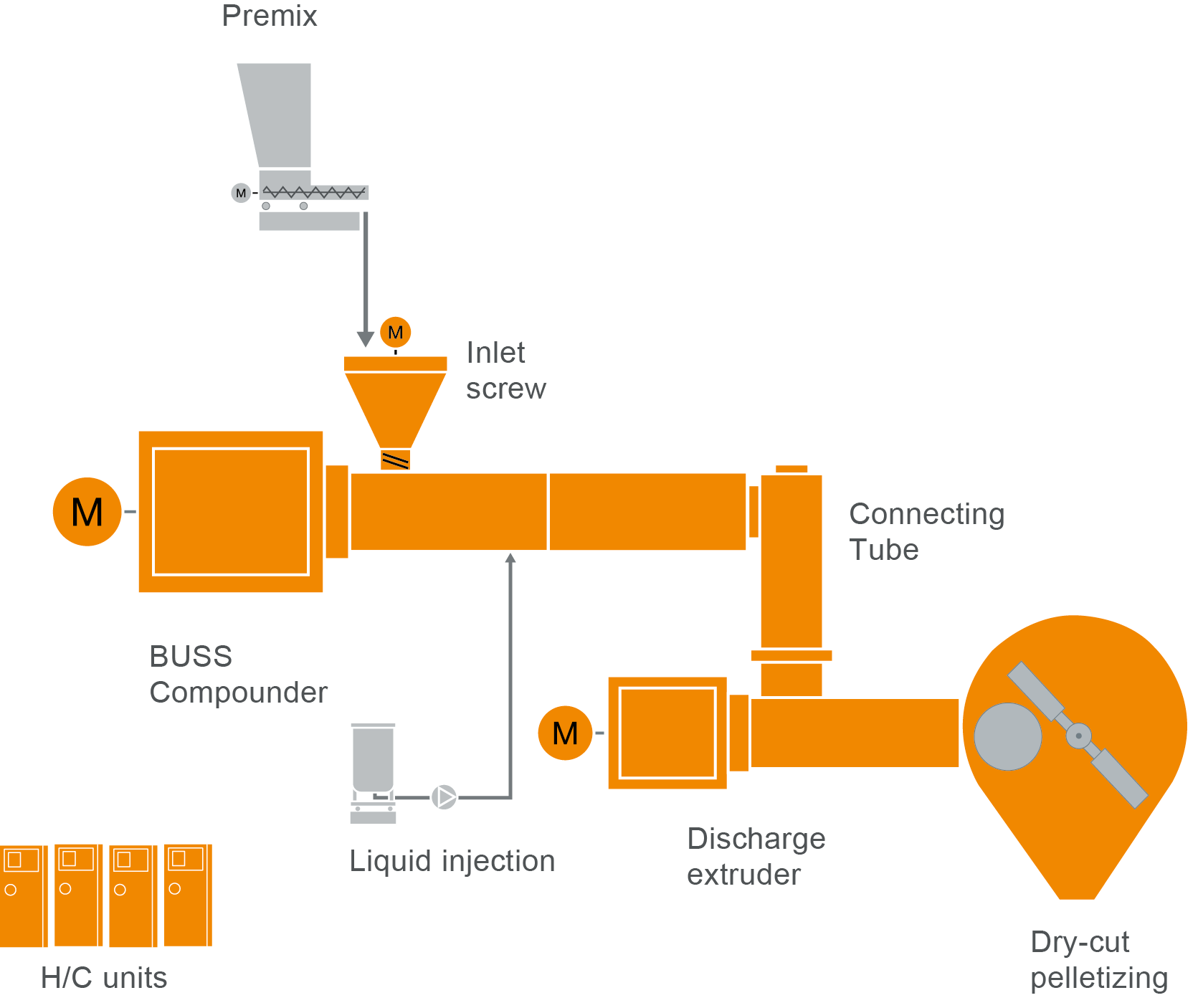

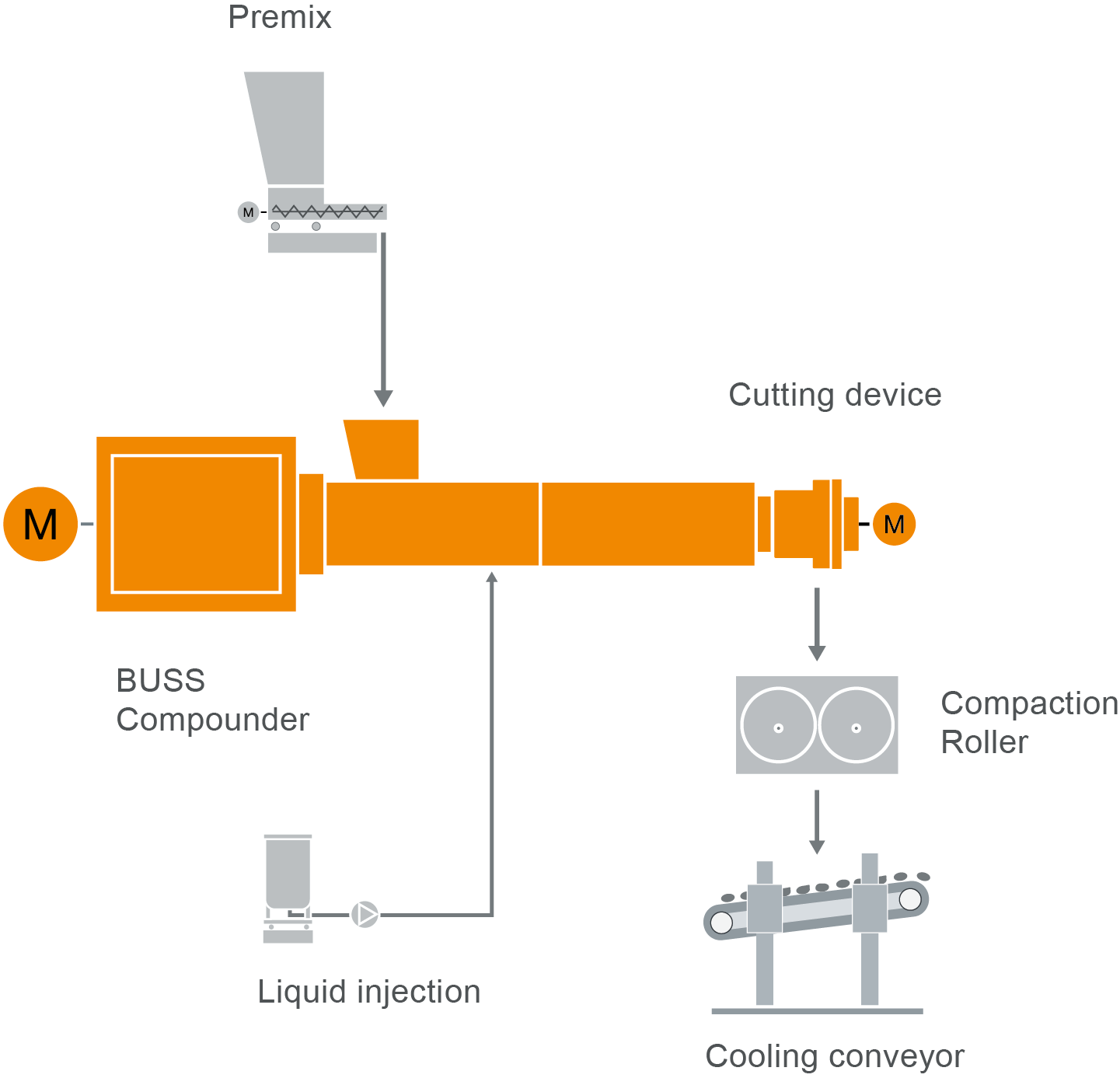

After the preparation step, the products are rolled out and broken. For some product groups such as phenoplasts and melamine resins, hot granulation is also possible. This results in further product benefits compared to alternative preparation methods.

Augmented with the widely supported BUSS compounding process expertise, the BUSS Co-Kneader is the first choice for continuous compounding of thermosets. The large number of systems installed in the field long since bears witness to this.

COMPEO compounder for thermoset compounding

Take a look at our typical plant layout for the production of thermosets in our COMPEO showroom.

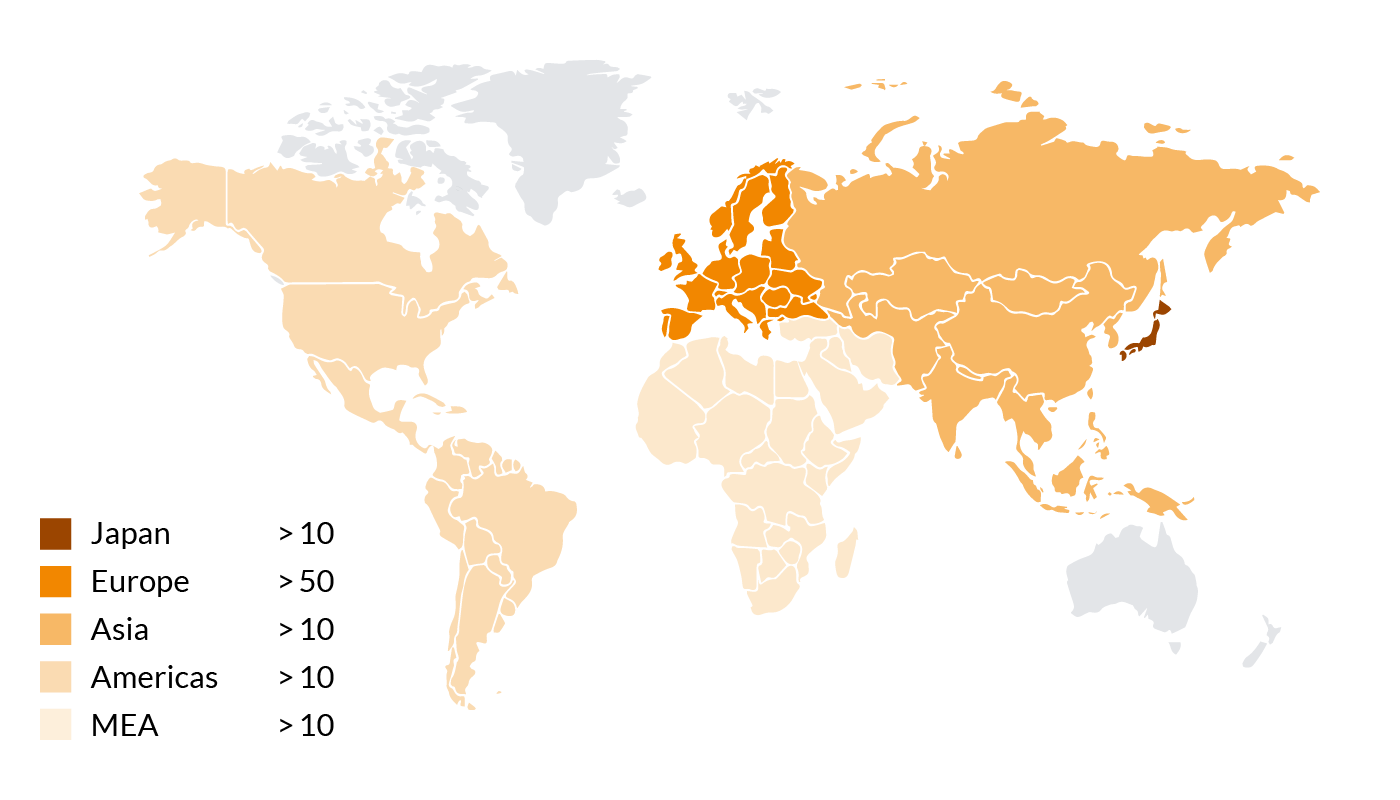

BUSS Co-Kneadersworldwide

Our patented Co-Kneaders are used worldwide nowadays, supporting our customers in the production of plastics. Using the BUSS compounding systems, our customers can master all the demanding requirements for thermoset compounding.

Number of Co-Kneaders used for thermoset compounding