Thermoplastic elastomers (TPE) form a family of materials which combine the properties of elastomers with the recyclability and processing advantages of plastics. TPEs do not require any vulcanization and can be processed using traditional processing methods such as injection molding, extrusion and blow molding.

Like thermoplastics, TPEs are plasticized by heat addition and demonstrate elastic behaviour again when cooled off. However, as opposed to the chemical conductive network of elastomers, TPE is a physical linkage, which is also reversible with new heat input when the melt point is exceeded. When cooling off, conductive network points are formed, which connect the elastic blocks, forming solid, spatial cross-linkage.

Thus, elastic properties arise which are comparable with those of elastomers and which, as for thermoplastics, enable repeatable forming processes. Therefore, they are also free-flowing and formable. TPEs consist of a block structure (A-B-A), which is typically distinguished by thermoplastic ends (A) and elastic chains (B). This structure places TPEs centrally between thermoplastics and elastomers. Moreover, ISO/EN/DIN 18064 classifies the designations of the wide range of TPEs in 7 classes: TPA, TPC, TPO, TPS, TPU, TPV and TPZ. The 3rd letter stands for the respective sub-class. A stands for amides, C for copolyesters, O for olefins, S for styrene, U for urethanes, V for vulcanizing agents and finally Z for various materials.

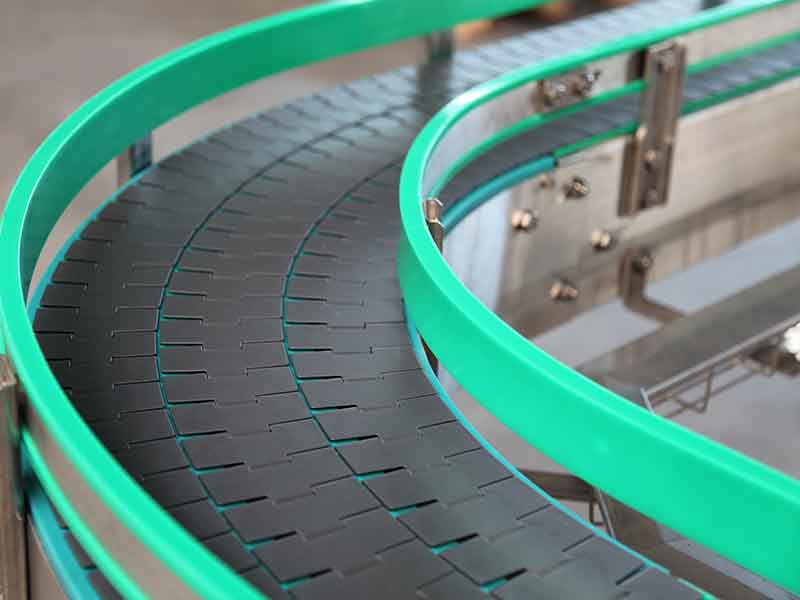

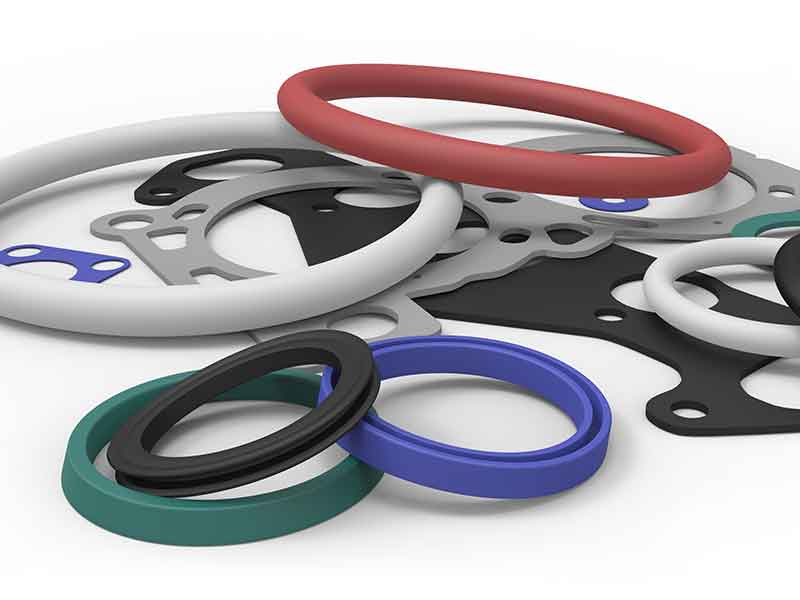

Typical areas of application

The huge scope of the property fields such as softness/hardness from low Shore A to high Shore D values, application temperatures from -60°C to 150°C and also the excellent combinability with other plastics sometimes result in very challenging compounding tasks.

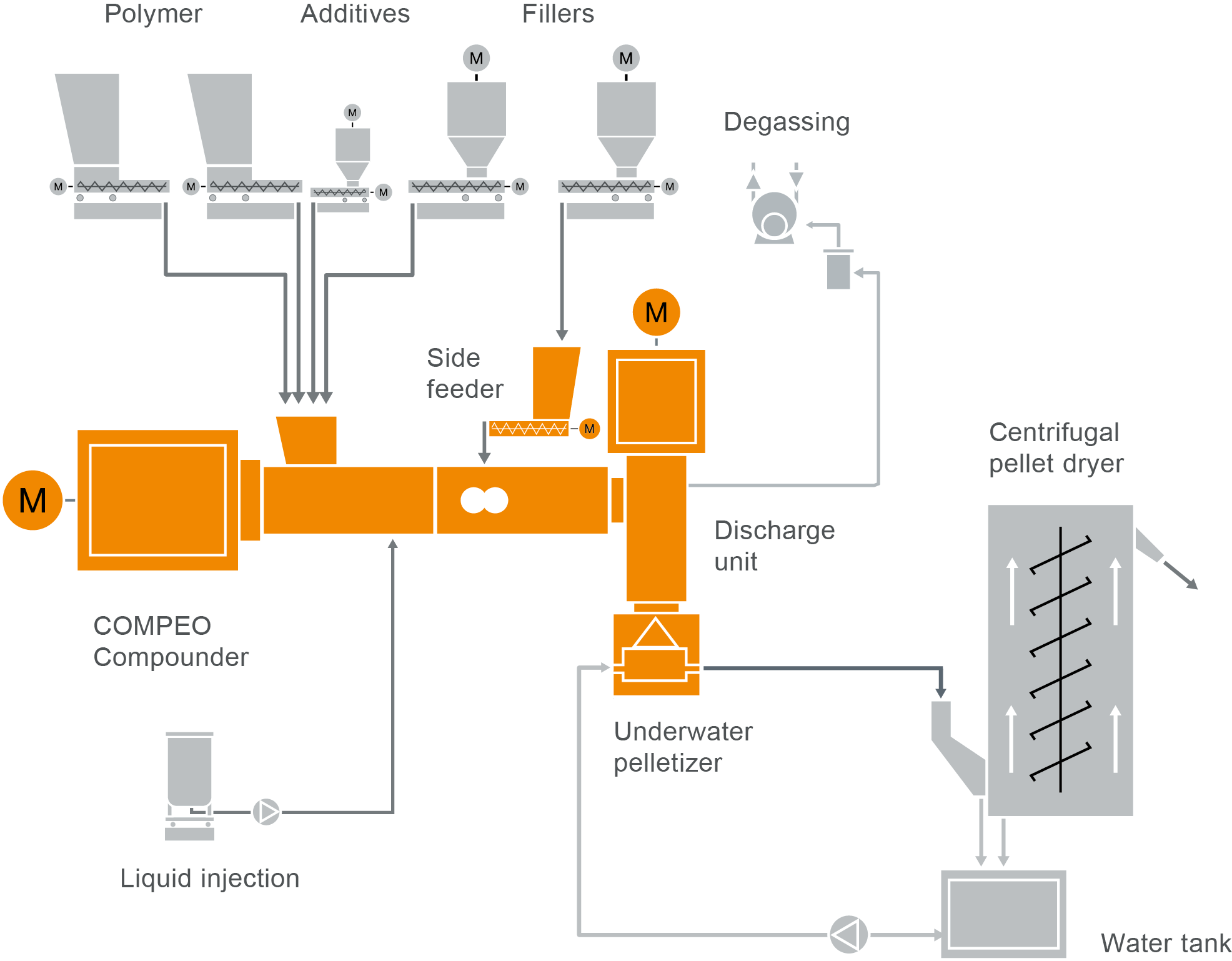

Therefore, powdered materials such as fillers, flame retardants, additives or also liquids such as various types of oil, reagents or liquid additives must be incorporated into the compounding process. The polymer components’ softening ranges and viscosities viscosities may vary considerably.

All these challenges are mastered well by the sophisticated process technology of BUSS compounder lines for thermoplastic elastomers. As opposed to other compounding systems, the BUSS Kneader can play out its strengths considerably better with these special compounds.

Advantages

The advantages of BUSS compounding technology for processing TPE

Compounding requirementsCompounding from TPE

These high requirements are accommodated and implemented using sophisticated processes. When directly compared with alternative systems, the BUSS Kneader can leverage its specific strengths very well: the moderate and adjustable shear rates dissipate the melting energy very efficiently. Overburdening with hotspots, which is commonplace in other systems, is therefore not incurred. In the compounding line’s mixing zones, even the highest aggregate content can also be controlled excellently thanks to the very high number of mixing cycles. If reactive modification is required, the liquids are injected directly into the melt pool at the optimum positions using hollow-drilled kneading pins and mixed over the shortest possible distance. Dynamic vulcanization processes are also mastered.

With the BUSS Kneader two-stage system, compounding and the pressure build-up step are strictly decoupled. This enables optimization of the process steps independently of each other. Here, normally a flange-mounted discharge extruder is used as a pressure build-up device for granulation or further processing of TPE compounds.

The hinged BUSS Kneader housing enables fast access to and high availability of the compounding system. The modular and therefore adjustable structure of the entire line and the widely supported BUSS process expertise make the BUSS Kneader an excellent choice for compounding TPEs in all classes, as witnessed by several line field installations.

Typical line layout

COMPEO compounder for TPE compounding

Find out more about the setup of a line layout as is typically used when TPEs are produced using our COMPEO compounders.