Bioplastics have already existed for a very long time. The first industrially produced plastics were cellulose-based and produced industrially as of 1869 and casein, which was produced in large quantities at the beginning of the 20th century as so-called synthetic horn. The discovery of plastic manufacturing based on crude oil in the early 20th century replaced the bioplastics fast and for several decades because it enabled considerably cheaper plastics production.

It was not until the 1980s that increasing crude oil prices and a gradually changing ecological conscience brought new, interesting developments in the field of bioplastics, and with it new compounding systems for production.

Typical areas of application

Its main applications are packaging, consumer goods and technical components from the transport and construction industry.

The term bioplastics or biopolymers is still not used in a uniform manner. It generally summarizes a large number of plastics which meet at least one of two criteria:

- bioplastics consist at least one part from renewable (plant-based) raw materials. Virtually all bioplastics are bio-based.

- Bioplastics are biodegradable, i.e. they can be broken down into water and CO2 by naturally occurring microorganisms, producing a small amount of biomass. Bioplastics from fossil raw materials can also be biodegradable.

Both these properties which either occur in isolation or jointly are used to define bioplastics: bioplastics are bio-based, biologically degradable or both together. Traditional plastics meet neither of these criteria. The biogenic raw materials or biological macromolecules which exist in nature such as proteins as well as materials filled with or reinforced with natural fibres are not meant by this.

Benefits

BUSS compounding systems offer the following specific benefits

Compounding requirementsfor bioplastics

Excellent dispersive and distributive mixing processes at moderate shear rates and low product temperatures are the key prerequisites for compounding bioplastics in order to ensure the lowest possible molecular weight degradation and thus the desired properties.

The gentle integration of fibres, fillers and additives often requires multiple splitting of the dosage flows and, if applicable, also the injection of liquid additives at defined positions in the compounding machine.

The BUSS Co-Kneader can demonstrate its specific abilities especially well in these applications: the enormously high number of mixing cycles at moderate, adjustable shear rates due to the operating principle allows top mixing efficiency on short process sections with narrow dwell time spectra. With the BUSS Co-Kneader's two-stage system, compounding and the pressure build-up step are strictly decoupled.

This enables optimization of the process steps independent of each other. The hinged BUSS Co-Kneader housing secures quick access to and high system availability.

The modular and therefore adjustable structure of the entire line and the widely supported BUSS process expertise make the BUSS Co-Kneader an excellent choice for compounding technical bioplastics.

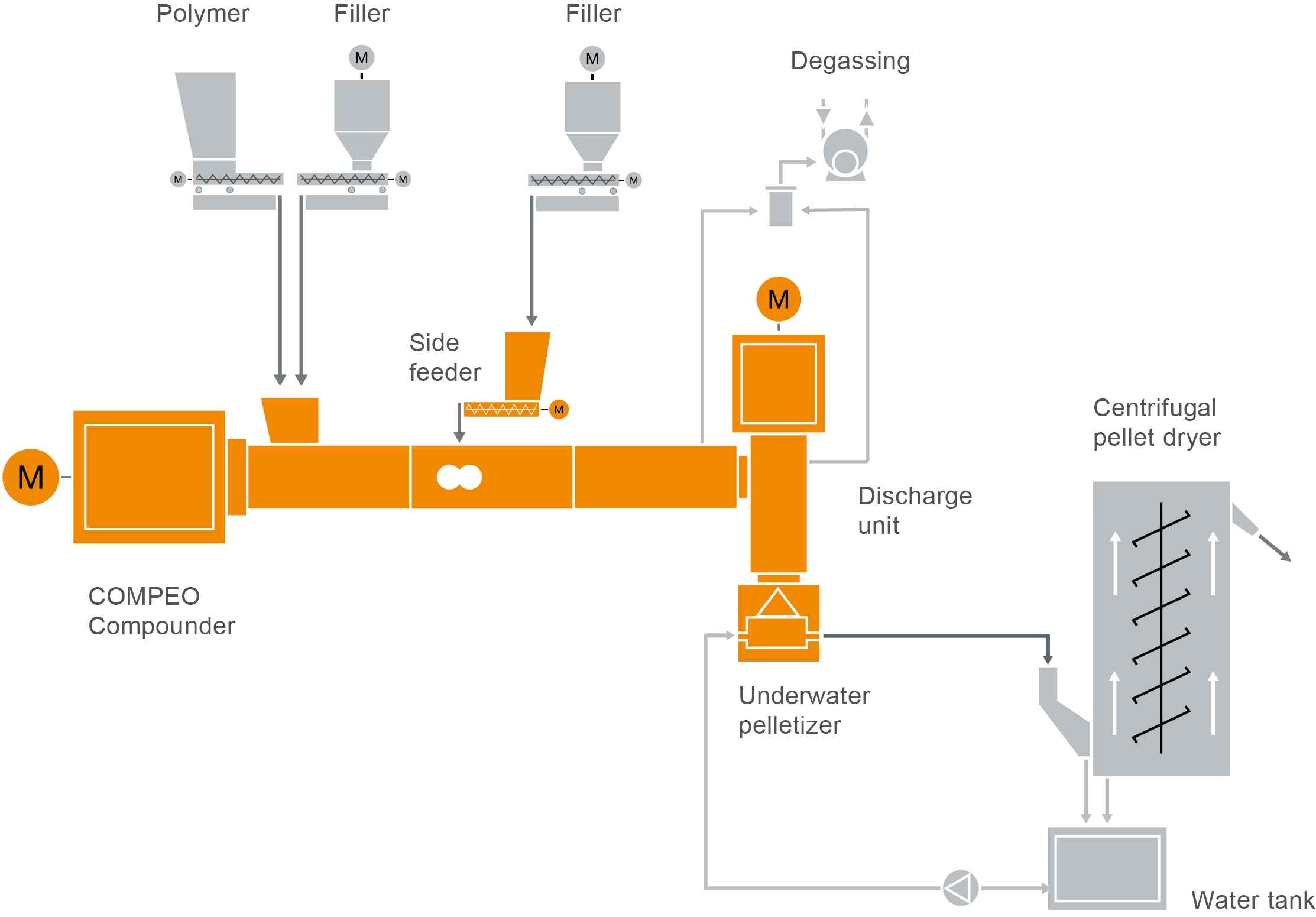

Typical plant layout

COMPEO compounder for bioplastics compounding

Take a look at our typical plant layout for the production of bioplastic compounds in our COMPEO showroom.