The creation of PVC from vinyl chloride (VC) was first described during the first half of the nineteenth century. Large-scale PVC production started around 1928 in the USA and 1930 in Germany. By the time the Second World War ended, it was already the most-produced plastic. With a chlorine content of 56.7% molar mass, PVC is a welcome co-product in chlorine production. Due to their low content of hydrocarbon-based components, PVC materials have a comparatively favorable energy balance and carbon dioxide footprint.

The addition of plasticizers and further additives for PVC compounding customizes the property profiles for the applications. From a mechanical view, the plasticizers can be viewed as “spacers” or “hinges” for neighbouring macromolecules. They allow greater freedom of movement for the PVC chain segments in the compounding system. The larger the plasticizer molecules selected, the lower the migration under extreme load.

Typical areas of application

The wide temperature limits from -50 to 70°C continuous temperature allow a variety of applications such as hoses, plugs and buffer elements in apparatus engineering. Good electrical insulation properties render Soft PVC the preferred wire and cable insulation for voltages of up to 10 kV.

In the building sector, soft PVC (PVC-P) is widely used. This is how building seals, joint and window seals, expansion, sliding and cover profiles, floor, table and wall coverings and much more are realised.

In medical technology, highly demanding systems for banked blood and infusion solutions are manufactured exclusively from PVC-P compounding.

Many other fields of application in the automotive, packaging and clothing industries have already existed for a long time and are constantly developed further.

Benefits

The benefits of the BUSS compounding technology for soft PVC processing

Compounding requirementsfor soft PVC

Soft PVC is normally processed via hot/cold mixing in the powder phase. Compounding then takes place on the BUSS Co-Kneader for all molding processes where granules are required, such as injection molding. If high aggregate content or specific quality requirements are required, this two-stage process is also applied. For simpler formulations, molding from the powder premix can suffice.

The requirements of soft PVC compounding can be described as follows: the pulverized dryblend, which in addition to the PVC resin contains further formulation components such as stabilizers, additives, filling and reinforcing materials as well as flame retardants must be dispersively and distributively intensively mixed, gelled and broken down in the compounding machine. Here, clearly defined temperature limits must be maintaned.

The BUSS Co-Kneader excels with uniform, moderate and if necessary, adjustable shear rates. The compounding process and the pressure build-up step are strictly separated and optimized in a two-stage system. Low specific energies with the most intense mixing processes, volumetric scale-up procedures and maximum availability are possible thanks to wide operating windows, underlining the technological and market leadership gained in soft PVC compounding technology since the beginning of mass production in the mid twentieth century.

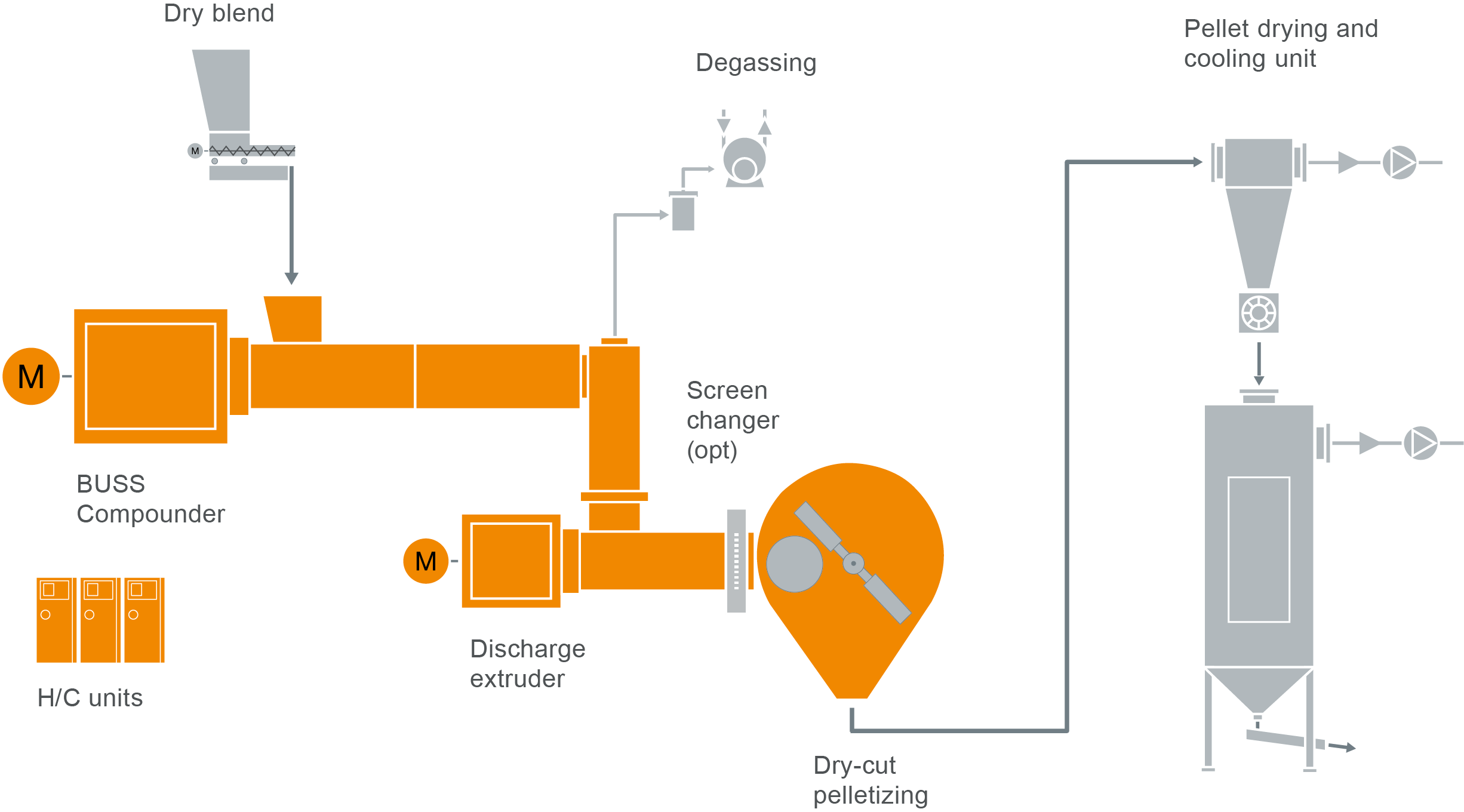

Typical plant layout

COMPEO compounder for PVC compounding

Take a look at our typical plant layout for the production of PVC compounds in our COMPEO showroom. You not only see our compounders there, but also the further aggregates necessary for the production process.

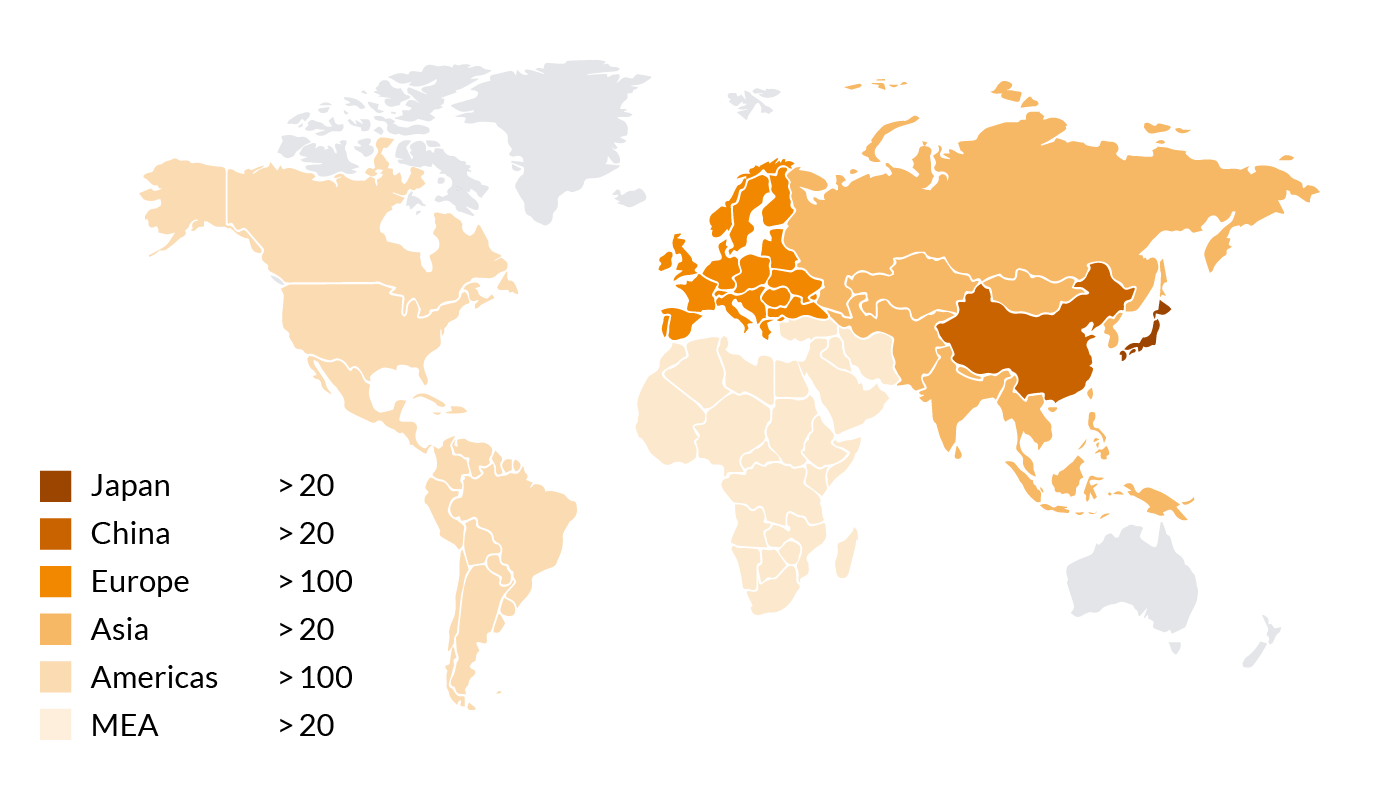

BUSS Co-Kneadersworldwide

Patented BUSS Co-Kneaders are in operation worldwide today supporting our customers in plastics production. With BUSS PVC compounding systems, our customers easily handle all the demanding requirements.

Number of Co-Kneaders used for PVC compounding