Polyethylenes (PE) demonstrate excellent insulation properties. A temporary increase in temperature, e.g. due to a load peak in the application as cable insulation can, however, cause full functional failure: the relatively low softening or melting ranges cause thermomechanical failure or even dripping off the insulation.

With the crosslinking of the polyethylene (PEX stands for cross-linked PE), a thermoset material can be made from the thermoplastic material. This can be used at considerably higher operating temperatures, has better mechanical properties, is more stable against organic fluids and often allows thinner wall thicknesses.

Various crosslinking methods are used. The silane crosslinked cable compounds are also described as PEX-b or Sioplas®.

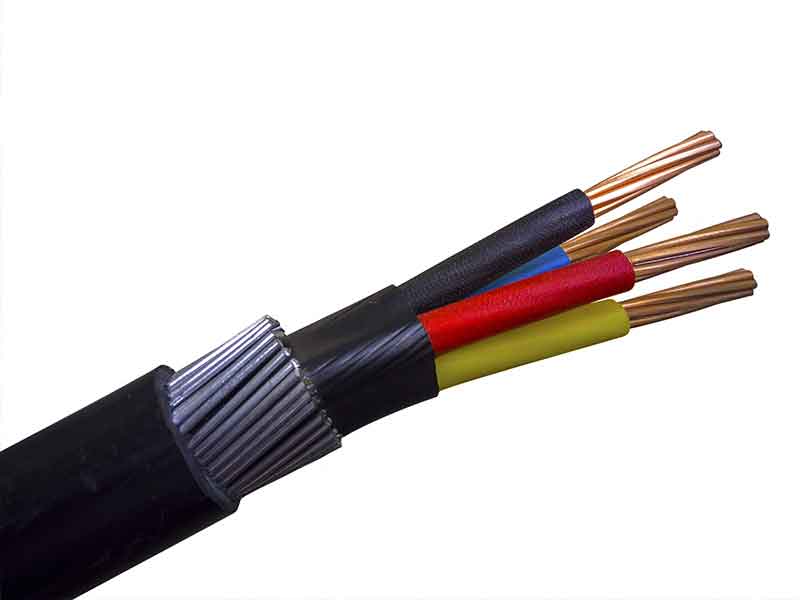

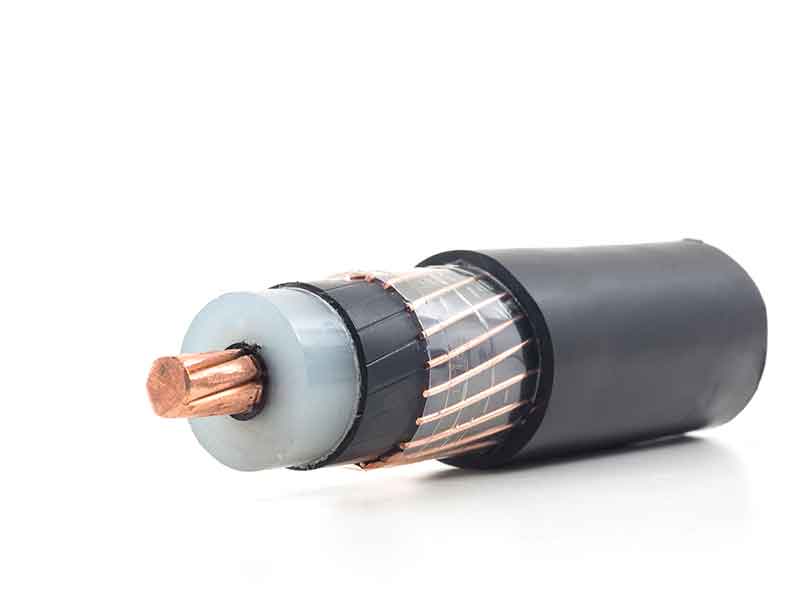

Typical areas of application

The XLPE Sioplas® process was developed by Midland Silicones (now Dow) in 1968. In a two-stage process, a peroxide-activated grafting of the vinyl silane onto the polymer chains is realised during the initial process step. In the second step, the grafted compound is extruded as cable together with a masterbatch using conventional extruders.

The crosslinking process takes place offline in a water or steam atmosphere. Since this process was developed, BUSS Co-Kneaders have been used for the first step and for manufacturing the catalyst masterbatches.

Silane cross-linked cable compounds on a PE basis have proven themselves globally as the most economical for use in cable insulation applications up to voltages of 10 kV and are manufactured in large quantities.

Benefits

BUSS compounding systems for silane cross-linked cable compounds (Sioplas® Process) offer the following specific benefits

Compounding requirementsaccording to the Sioplas® process

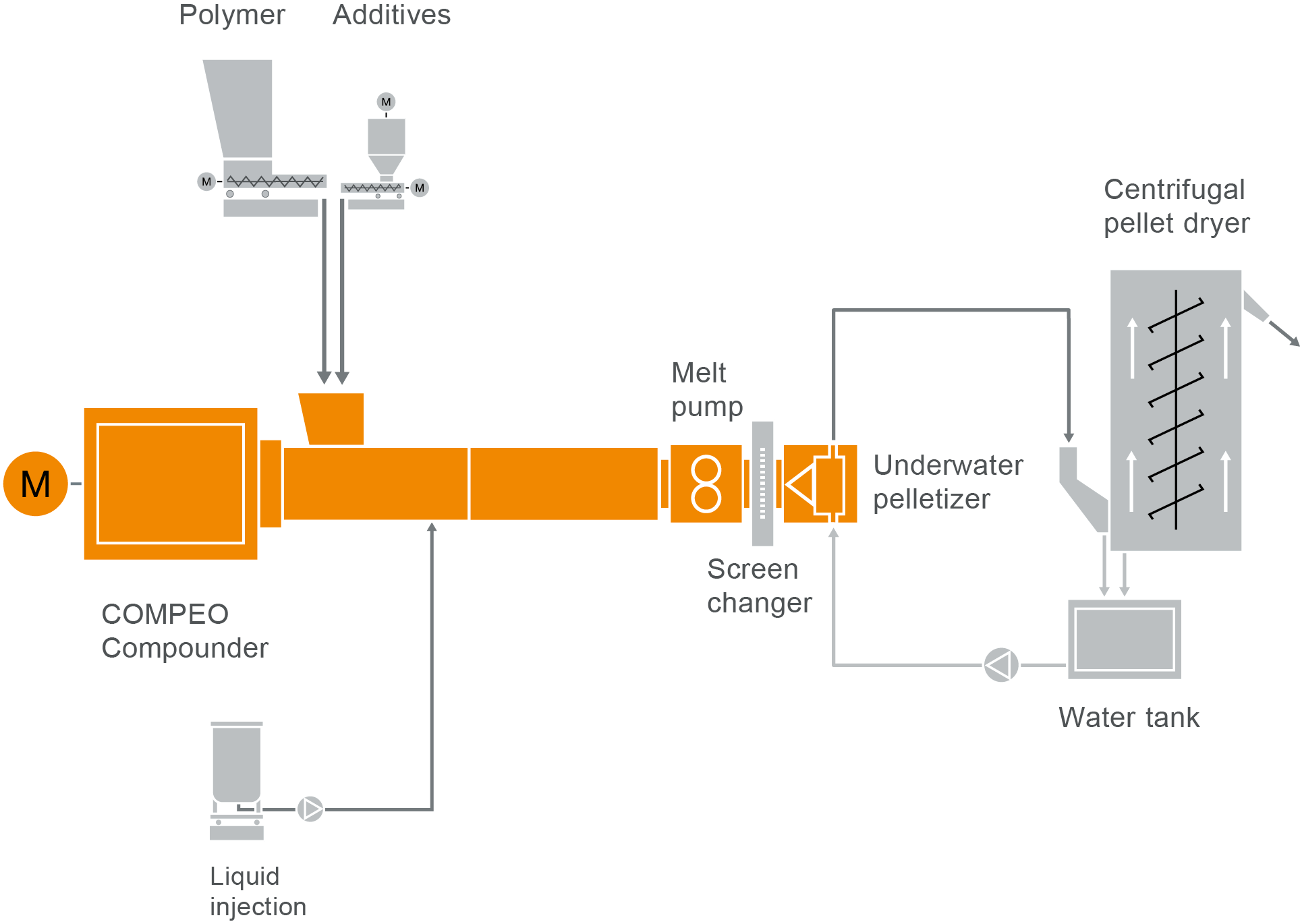

The grafting process requires targeted process management with regard to temperature profile and residence time. The liquid silane peroxide mixture is dosed into the polymer melt via a gravimetric membrane or piston dosage pump and intensively mixed distributively. The silane molecules are bonded to the polymer chains via radical grafting. This process requires specific timing at corresponding temperatures.

In this reactive compounding process, the following properties of the BUSS Co-Kneader within the compounding system are of central significance for the production of silane cross-linked cable compounds: The silane peroxide mixture can be directly injected into the melt pool at the optimum position in terms of process technology. The immediate onset of distributive mixing allows evenly high grafting utilisation and minimizes scorching effects compared to alternative systems.

The silane crosslinking process can be monitored by compound temperature measurements in the process zone at all times. This allows online quality assurance and control.

The pressure build-up step is implemented with a pre-pressure controlled melt pump which feeds underwater granulation for shaping. Therefore, it can be optimized independently. The hinged BUSS Co-Kneader housing ensures quick access and high system availability. All these competences together are why BUSS compounding technology excels in the production process of silane cross-linked cable compounds.

The modular and therefore adaptable structure of the entire compounding system and widely supported BUSS process expertise make the BUSS Co-Kneader the best choice since development of the process for compounding silane cross-linked cable compounds for cable insulation and offer maximum investment security.

Typical plant layout

COMPEO compounder setup for manufacturing silane cross-linked cable compounds

Take a look at our typical plant layout for silane cross-linked cable compounds in our COMPEO showroom.

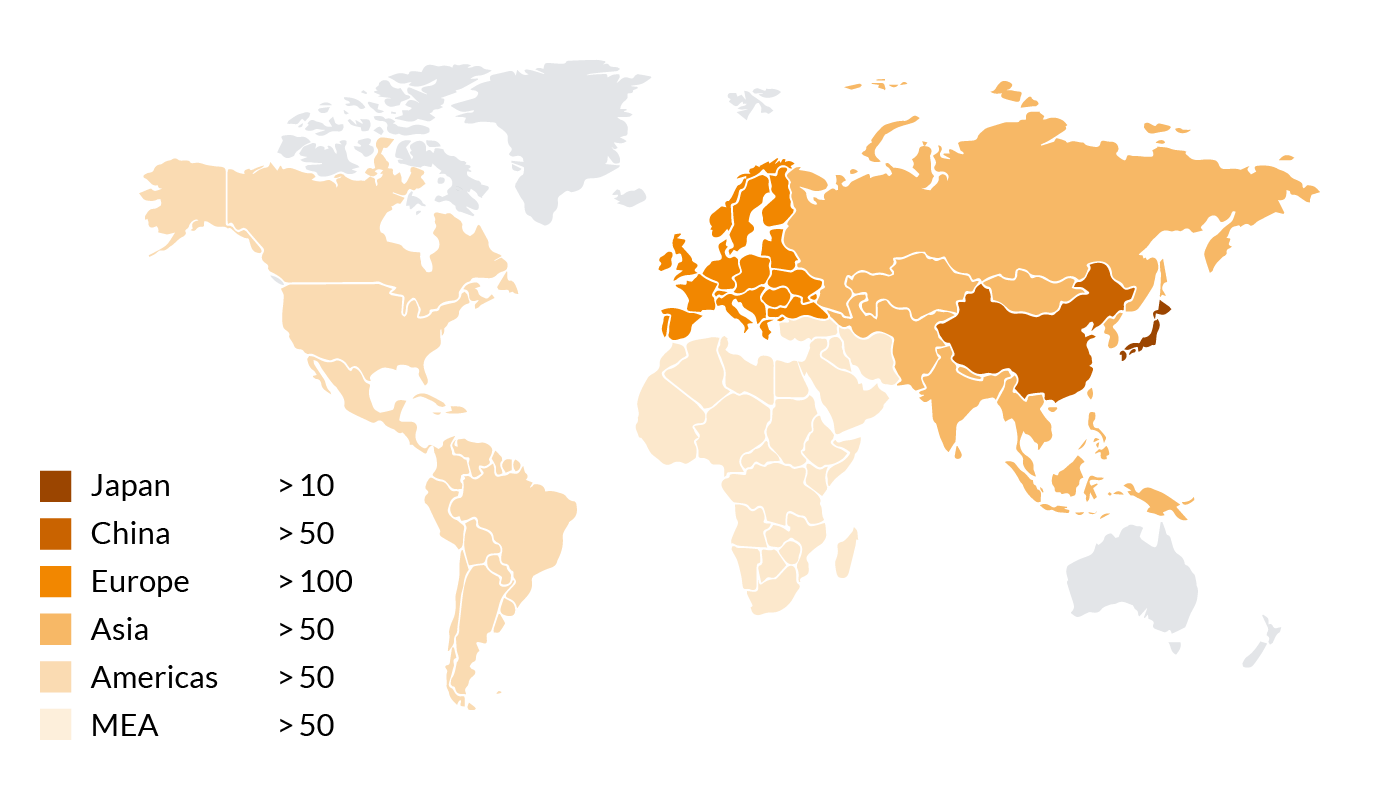

BUSS Co-Kneadersworldwide

Our patented Co-Kneaders are used worldwide nowadays, supporting our customers in the production of plastics. With BUSS compounding systems, our customers can master all the demanding requirements for manufacturing silane cross-linked compounds.

Number of Co-Kneaders used for manufacturing cable compounds