In addition to thermoplastics and thermosets, elastomers are the third important main plastics group. Elastomers are dimensionally stable, but elastically deformable plastics with a glass transition point below room temperature. The plastics can be deformed under tension, shearing and pressure loads, but then revert to their original not deformed shape.

From a chemical aspect, elastomers are macromolecules which are only irreversibly joined by a few wide-mesh cross-linking bridges. These cross-links can be degraded for thermoplastic elastomers under the influence of heat, so that they demonstrate thermoplastic behaviour.

Modifications to rubber compounds enable the manufacturing of elastomers with customized degrees of hardness, conductive network densities and operation temperatures.

Typical areas of application

Excavations in Guatemala have shown that already in the 3rd century, the Maya knew rubber as a material. Since the 18th century, more and more applications have been described.

The invention of the vulcanization process by Charles Goodyear in 1839 enabled stable elastic properties both in cold and hot conditions and thus also the breakthrough to technical applications. At the beginning of the twentieth century, German chemists succeeded in producing synthetic rubber.

Benefits

BUSS compounding systems offer the following specific benefits

Compounding requirementsof rubber compounds

The traditional production method for elastomers is preparation on internal mixers or rolling mills. This established process provides advantages such as maximum flexibility, precise offline dosage of even the smallest formulation proportions, as well as variable dwell and mixing times.

However, limitations such as high specific energies, interim storage times and also property fluctuations between individual batches emphasize the advantages of continuous processing in the compounding machine: the typical strength profile includes uniform process conditions, narrow residence time distribution and the integration of process steps.

With precise temperature control, the BUSS Co-Kneader can also offer the option to mix high filler proportions excellently and at the same time gently and to inject liquid formulation components such as plasticizer oils or reagents directly into the process chamber at the optimum position.

The wide use of the BUSS Co-Kneader as a processing system for silicone and fluororubber has been known for several decades and highly valued by its users.

Recently, a wide range of further application fields has been added to BUSS compounding technology: here, the integration of process steps, the extension of requirements profiles and the use of alternative formulation components play the major roles.

These high requirements are accommodated and implemented using sophisticated processes. The processes are developed, optimized and also the initial scale-up steps can be realised with a throughput factor of 10 at the BUSS technical centre.

If required, two BUSS Co-Kneader stages can be combined. The pressure build-up step is strictly decoupled from the preparation process here. Thus, the process steps can be optimized, independently of each other. Here, normally a flange-mounted discharge extruder is used as a pressure build-up device for granulation or further processing.

The BUSS Co-Kneader's hinged housing ensures fast access to and high availability of the compounding system. The modular and therefore adjustable structure of the entire compounding system and the widely supported BUSS process expertise make the BUSS Co-Kneader system an excellent choice for compounding elastomers and rubber compounds.

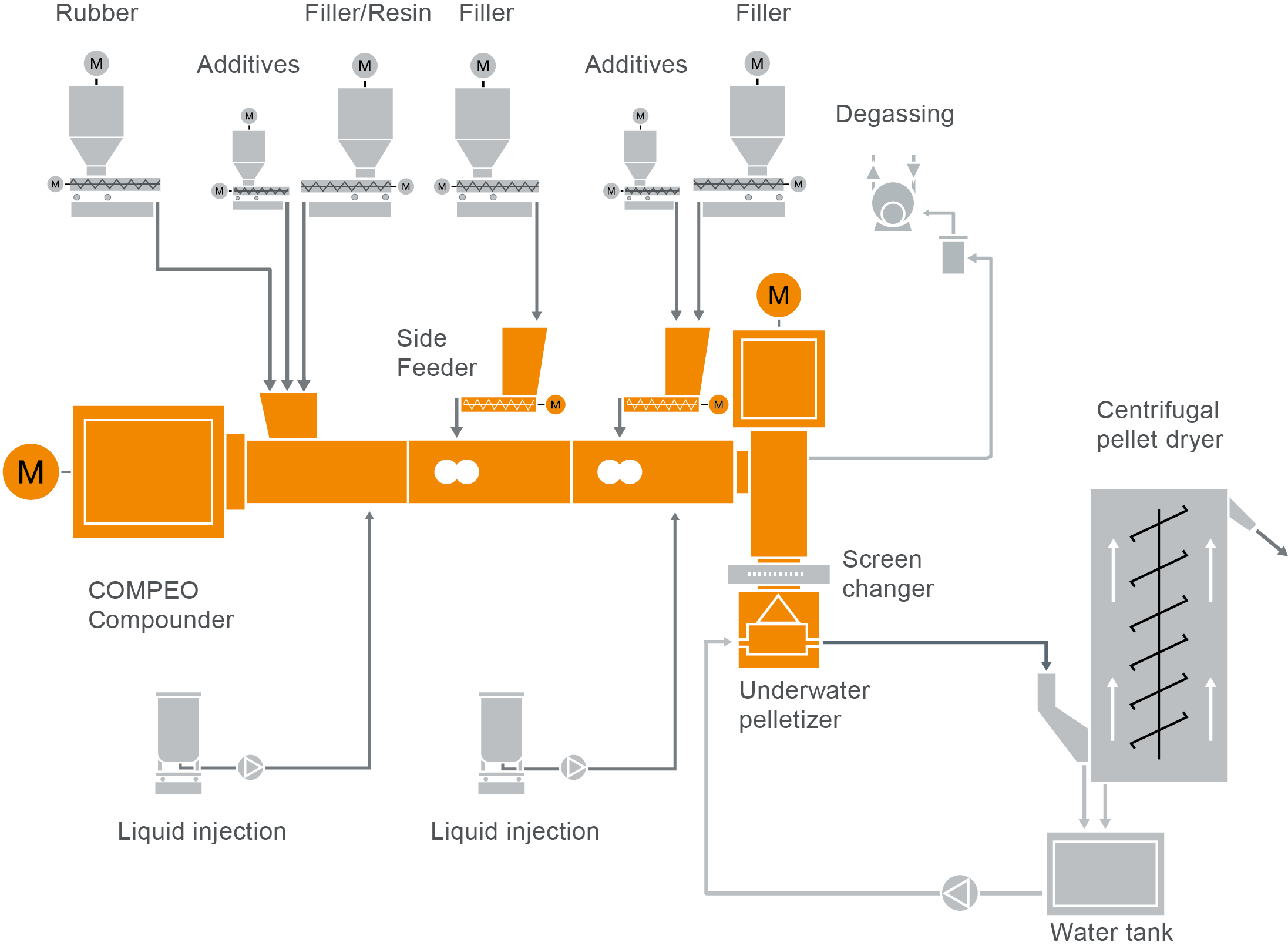

Typical plant layout

COMPEO compounder for rubber compound production

Take a look at our typical plant layout for rubber compounds in our COMPEO showroom.