Nowadays, powder coatings are generally understood to be thermoset powder coating, which is applied to surfaces via electrostatic application. With a burn-in and consequent crosslinking process, the surfaces receive their specific properties. These include both functional and decorative functions.

A huge color range of matt, semi-gloss and high-gloss colors, metallic effects, textures and soft-touch colors is available. The functional features range from antibacterial properties to corrosion protection. The major applications are general metal coating, household appliances, facade, furniture and car coating.

Polymer powder coatings have been used since the middle of the 20th century. Initially in the fluidized bed sintering process for which the component to be coated was preheated and immersed in a bath of swirled powder coating particles.

Here, high coating thicknesses of up to 500μm arose and arise up to current times. Initially, mostly thermoplastic plastics were used. During the 1960s, thermoset materials came to the fore step-by-step: epoxy, epoxy polyester (hybrid), polyester/PRIMID, polyester/TGIC, polyurethane as well as acrylate-based preparations.

Typical areas of application

In addition to the excellent coating properties, powder coatings can play numerous further trump cards: this means that you can fully do without solvents (with VOC and others).

This is clearly noticeable in the application, utilisation rate (up to 95%) and the environmental and energy-relevant aspects of the entire process in comparison to alternative systems. The clearly defined coating thickness in a coating process denotes a further positive aspect.

The development trends of new conductive network technologies (e.g. UV), low burn-in temperatures, thinner coating thicknesses and a widening of the substrate range (glass, wood, plastics) must be named. Moreover, customized formulations with correspondingly small batch sizes are becoming more important.

Benefits

BUSS compounding systems offer the following specific benefits

Compounding requirementsfor powder coatings

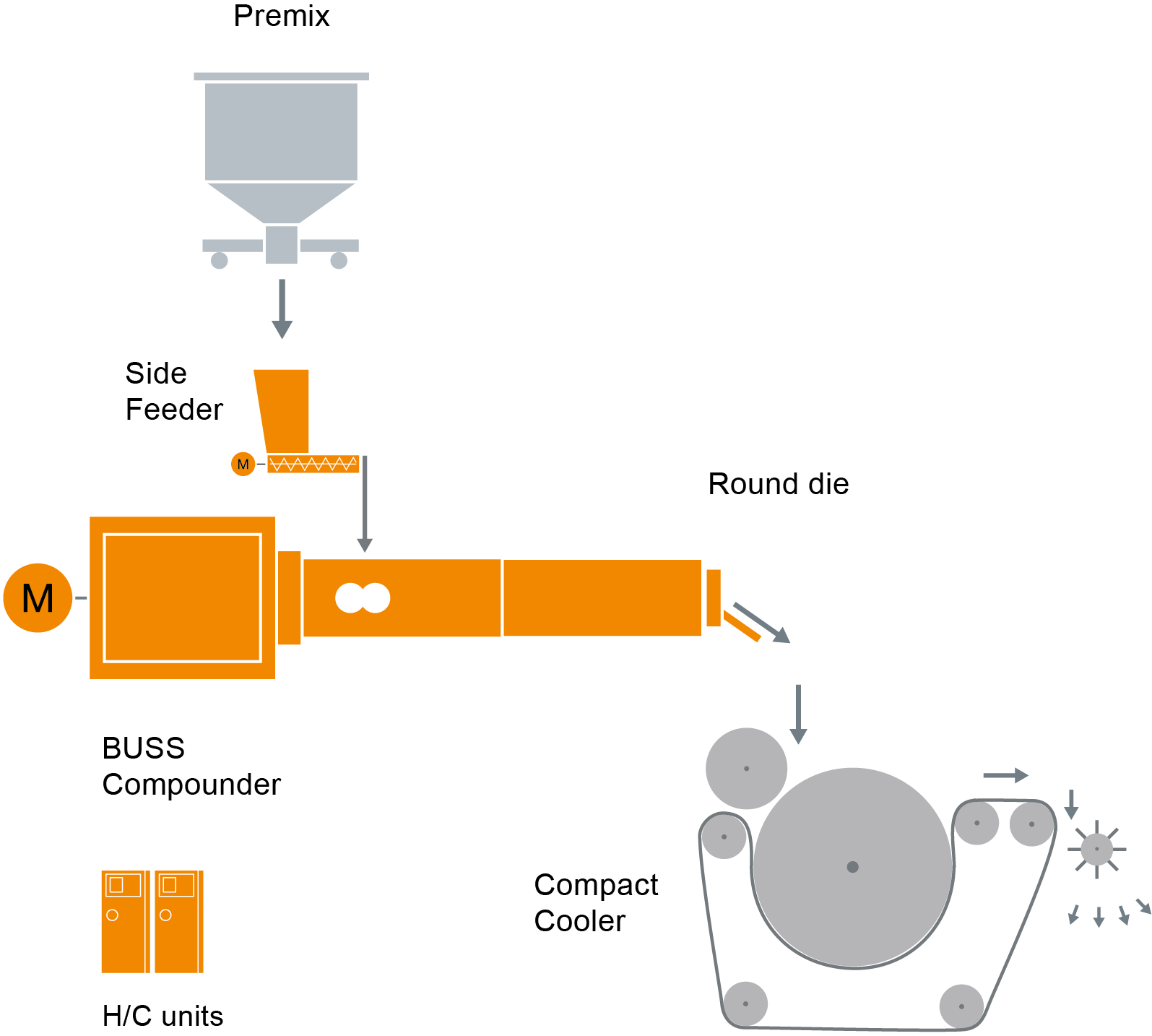

Powder coatings are produced in a compounding system in the solid phase by premixing the weighed-in components such as basic polymer, additives, pigments and fillers. The powder mixture is dosed to the BUSS Co-Kneader in the BUSS compounding system and compounded in the melt phase. The melt is then fed to a cooling device, e.g. a cooling belt, rolled out and crushed into chips in a shredder. These are ground and sifted for exact particle size distribution.

Outstanding dispersive and distributive mixing processes at low product temperatures, which are significantly below crosslinking temperatures of the basic polymers, are crucial for compounding. The BUSS Co-Kneader can demonstrate its specific abilities outstandingly in these applications: the enormously high number of mixing cycles at moderate, constant shear rates allows top mixing efficiency and therefore product quality with maximum throughput.

The proven shaft geometries cover a wide application range. The modular process configuration system allows simultaneous simple adjustments.

The hinged BUSS Co-Kneader housing assures fast access, ease final cleaning in case of extreme colour changes and high availability. The widely supported BUSS process expertise makes the BUSS Co-Kneader the first choice for compounding powder coating and has provided top investment security for over 60 years.

Typical plant layout

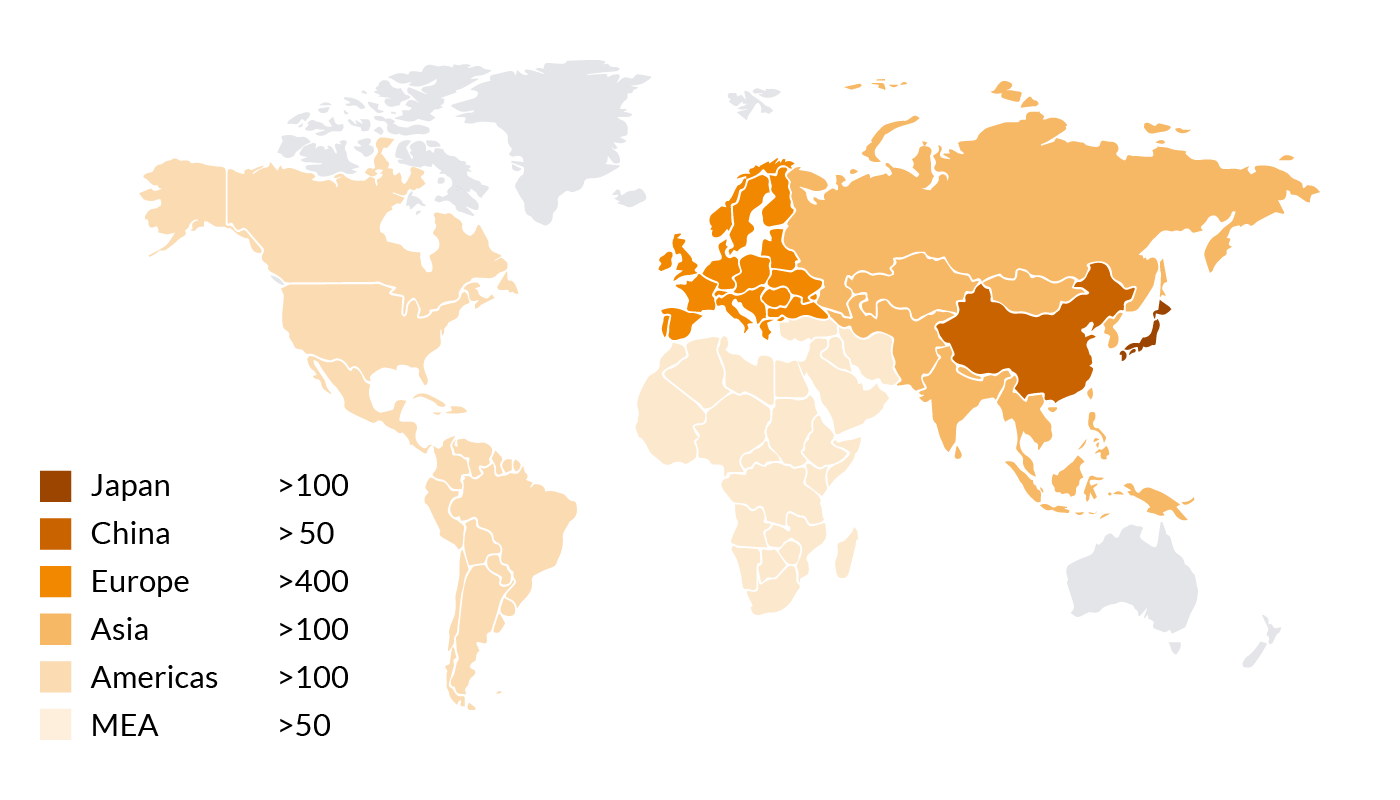

BUSS Co-Kneadersworldwide

Our patented Co-Kneaders are used worldwide nowadays, supporting our customers in the production of coatings. Using BUSS compounding systems, our customers can master all the demanding requirements for powder coating compounding.

Number of Co-Kneaders used for powder coating compounding