The polyamide-based (PA) compounds belong to the group of technical plastics. The term “engineering plastics” is often used. It basically describes the major strengths and therefore the fields of application: technical components with challenging mechanical and thermal requirements profiles and high chemical resistance in demanding surroundings.

Typical areas of application

Polyamides were invented by DuPont and launched in 1934. The original use in all kinds of materials and textiles was fast extended to injection molding and extrusion applications. In its further development, application temperatures and reduction of hydrolysis were in focus.

The partially aromatic high-performance polyamides, also referred to as polyphthalamides (PPA), achieve dimensional stability under heat of up to 280°C. The further excellent properties of PA include its high stiffness, good electrical properties s well as the option to achieve high flame retardant properties. All-in-all, a technically diverse polymer.

Benefits

BUSS compounding systems offer the following specific benefits

Compounding requirementsfor polyamide compounding

These specific property profiles are achieved via the compounding step. In several cases, reinforcement, filling flame retardant agents and further additives are used simultaneously. The compounding of these materials is accordingly demanding and requires customized solutions.

Such solutions are possible with the polyamide compounding system from BUSS. Therefore, it is important to introduce the specific energy as gently as possible, to distribute high shares of filler and flame retardant agents excellently and to enter the reinforcement fibers so that the maximum mechanical properties are achieved and at the same time the service life remains high in the respective process zones.

These requirements which partially run into each other are mastered well, using sophisticated processes. The BUSS Co-Kneader has proven itself over a long period when compounding these particularly demanding materials. The moderate and uniform, if necessary also specifically adaptable shear rates and with them precise temperature management of the BUSS Co-Kneader play the central role here: in the melting zone only as much energy as required is dissipated without overburdening the polymer components.

The fillers and flame retardants are optimally distributed within the shortest possible process length due to the high folding values, and downstream the reinforcing fibers are added, separated and wrapped if necessary in order to maintain the maximum fiber lengths.

Thus, also for the narrowest process windows, such as the PPA-based materials where the temperature range between melting and beginning degradation may only just be 30°C maximum property profiles are also achieved at top viscosity. With the BUSS Co-Kneader's two-stage system, compounding and the pressure build-up step are strictly decoupled.

This enables optimization of the process steps independent of each other. The hinged BUSS Co-Kneader housing secures fast access to and high availability of the compounding system. The modular and therefore adjustable structure of the entire line and the widely supported BUSS process expertise make the BUSS Co-Kneader within the entire polyamide compounding system a very good choice for compounding demanding polyamide compounds and offer top investment security.

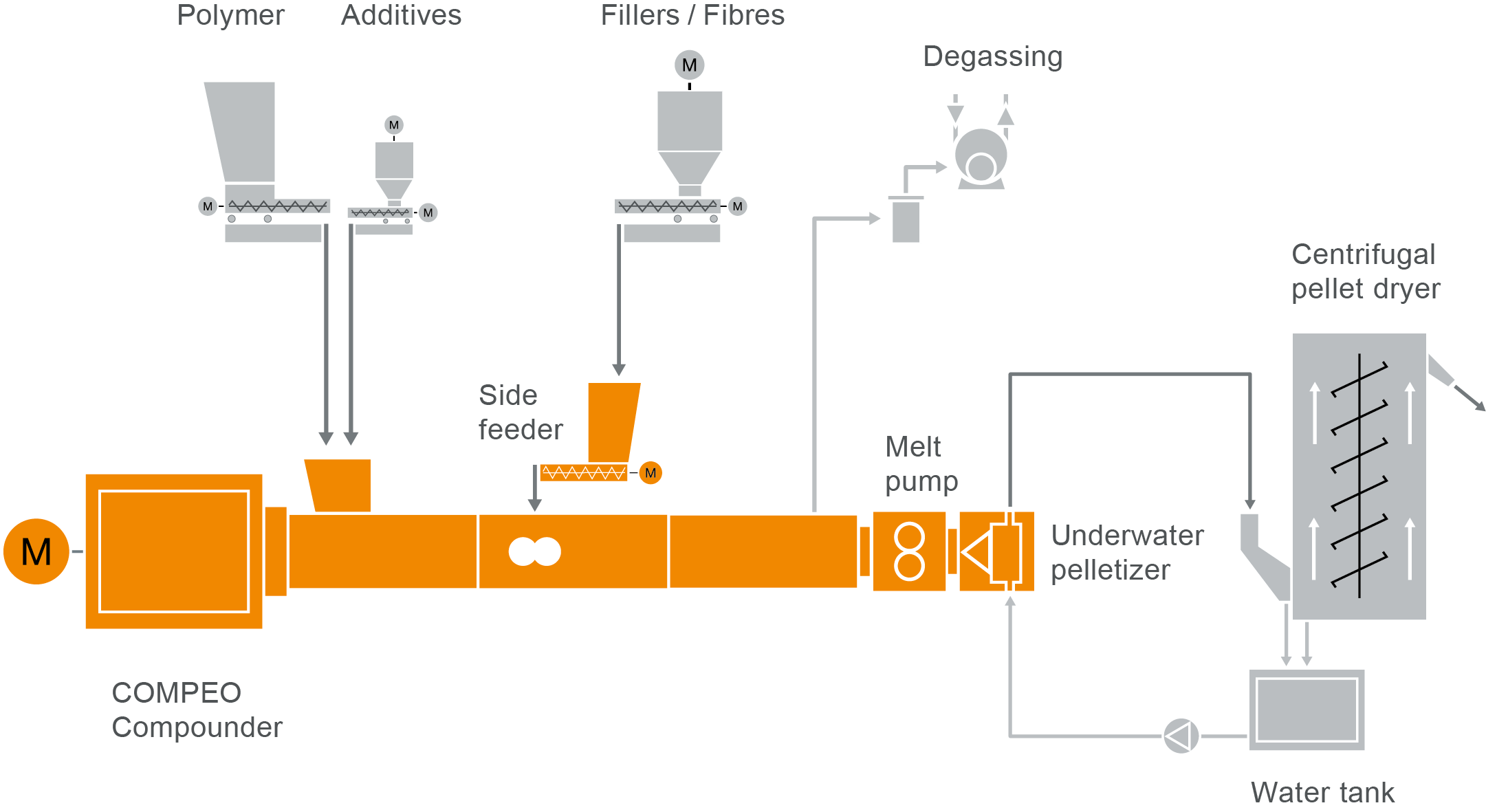

Typical plant layout

COMPEO compounder for PA compound manufacturing

Take a look at our typical plant layout for the production of polyamide compounds in our COMPEO showroom.