Wood was used for building houses and ships, flax and hemp fiber were processed as ropes and technical textiles such as sails and grain sacks.

In modern times and during the industrial revolution, new areas of application were added. Chemists developed tar pitch which helped when processing natural fibers as stable components and could be made available to various industries.

Typical areas of application

The specific properties of natural fibers were back then as also today the driving forces for the selection of these materials: the good mechanical strength properties such as tensile and impact strength, stretching and elasticity module coupled with a low weight.

The renewable raw material basis, the excellent CO2 and energy balances and last but not least also the competitive price let the applications and the volumes accordingly skyrocket. The most important fields of application include the transport- and aircraft industry as well as the construction industry.

Benefits

BUSS compounding systems offer the following specific benefits for NFC compounds

Compounding requirementsfrom NFC

For compounding systems for producing natural fiber-reinforced plastics, thermoplastic or thermosetting polymers are used as a matrix. For the thermoplastics, these can be P0E, PP, PS, PVC or also PLA. For the thermosetting products, they are mostly acrylate, epoxy and phenolic resins.

The most important fibres are flax, hemp, jute, kenaf, sisal, abaca and cotton. Wood fibres, wood flour or rice husks belong to the widely used materials. In several cases, customized adhesive agents are used to secure optimum joining of the matrix and the fibre.

Excellent dispersive and distributive mixing processes at low product temperatures are prerequisites for the compounding process of natural fibre-reinforced plastics in order to prepare the high content of typically 30-70% natural fibres and the additives in accordance with requirements and not to damage the natural fibres thermally. Multiple splitting of the dosage flows and, as applicable, also the fluid injection of adhesive agent additives at defined positions belongs to the requirements profile.

The BUSS Co-Kneader can demonstrate its specific capabilities excellently with these applications: due to the operating principle when compounding natural fibre-reinforced plastics, the enormous number of mixing cycles at moderate and uniform shear rates enables unsurpassed mixing efficiency and therefore product quality with maximum throughput.

The considerably lower wear and tear compared to alternative screw extruders is a side-effect of the moderate shear rates.

The process room has a modular structure and is designed by in-house experts specifically for the application. With the BUSS Co-Kneader two-stage system, compounding and the pressure build-up steps are strictly decoupled.

Therefore, the BUSS Co-Kneader process steps for compounding natural fibre-reinforced plastics can be optimized independently. The hinged BUSS Co-Kneader housing or retractable housing of the discharge extruder secures fast access and high system availability.

The modular and therefore adaptable structure of the entire line and widely supported BUSS process expertise make the BUSS Co-Kneader the first choice for compounding NFC Compounds.

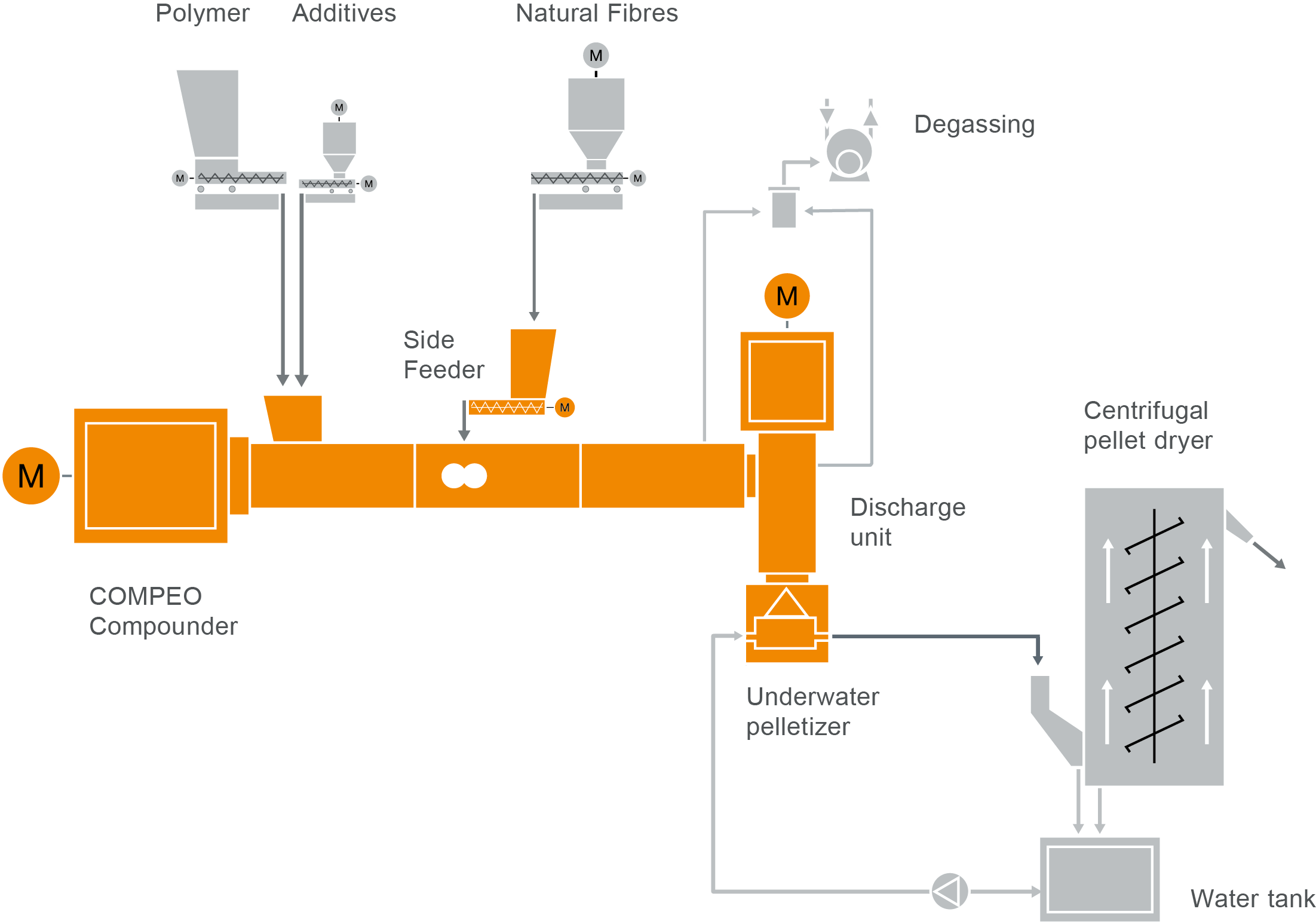

Typical plant layout

COMPEO for NFC compounding

Take a look at our typical plant layout for the production of natural fiber composites in our COMPEO showroom.

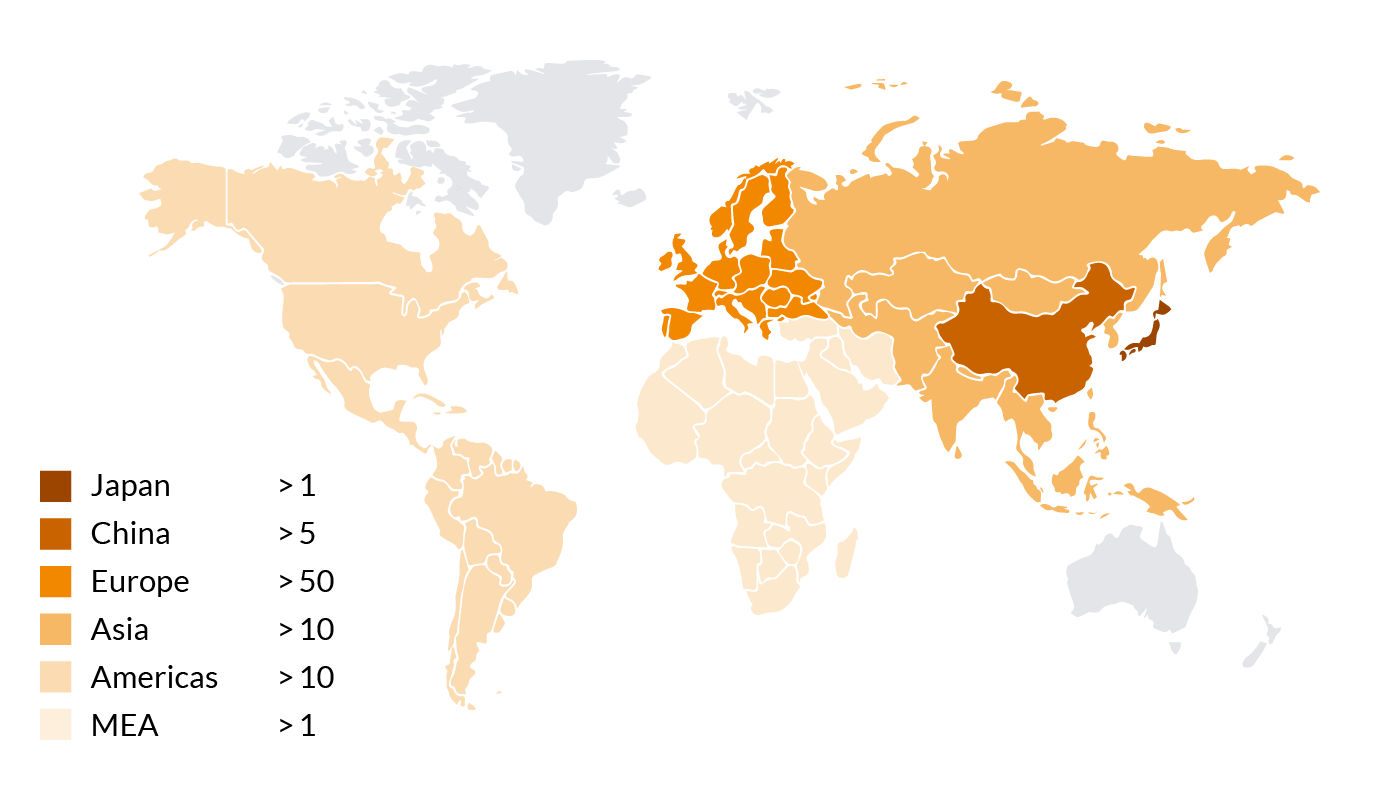

BUSS Co-Kneadersworldwide

Our patented Co-Kneaders are used worldwide nowadays, supporting our customers in the production of plastics. Using BUSS compounding systems, our customers can master all the demanding requirements for NFC compounding.

Number of Co-Kneaders used for NFC compounding