The term masterbatch (MB) is understood nowadays as a concentrate of colorants, additives or other ingredients, with which specific properties in the end application can be achieved cleanly and easily. Many of the ingredients exist in their initial form often as powders or liquids, which are difficult to handle or would require considerable processing efforts.

For example, this can apply to nanoparticle incorporation in a safe environment or the combination of several Granulation in a masterbatch compounder facilitates dosing and processing. This may also be possible with standard masterbatch compounders instead of more complex systems.

According to legend, the name “Masterbatch” originates from the times when the “master” was responsible for the recipes of certain batches, to which valuable and expensive additives were admixed.

Masterbatch preparation corresponds exactly with this classification because precisely dispensed mixtures are admixed with plastic or carrier substances into batches which are easy to process. In actual fact, the “masters” responsible for this are the masterbatch compounder operator’s specialists.

Typical areas of application

In principle, there are three masterbatch preparation methods:

- In many cases, the so-called premix process is used. All the formulation ingredients are mixed in the solid phase via a premix process, often including polymers in powder form. The premixtures are then volumetrically dispensed to a BUSS Co-Kneader for compounding.

- In the split feed process, the polymer is fed to the BUSS Co-Kneader in the melting zone while additives are dosed downstream to several feed points if required.

- The color matching method with separate feed of the primary colors enables rapid hue adjustments, for high-quality application fields and efficient color changing.

Thanks to multiple dosing flows, the BUSS Co-Kneader’s specific capabilities really come to the fore in such applications. Due to the operating principle, the enormous number of mixing cycles at moderate and uniform shear rates enables unsurpassed mixing efficiency with minimal polymer matrix content. As a side-effect of the moderate shear rates, wear and tear is significantly lower than with other screw extruders. The modular and therefore adjustable design of the entire compounding system makes it easily adaptable to all requirements and together with the widely based BUSS processing expertise, the BUSS Co-Kneader is first choice when compounding filler masterbatches.

Benefits

BUSS masterbatch compounders offer the following specific benefits

Compounding requirementsfrom the masterbatch

Masterbatches are split in three groups. The first group is color masterbatches which are used to dye plastic products. Additive masterbatches are used for properties such as flame retardant, antistatic or UV stabilization. The third group, the combination masterbatches, contains colorants and additive and are named after a combination of other masterbatch groups.

Excellent mixing results, moderate shear force and venting are properties which make BUSS Co-Kneaders ideal for masterbatches. The freedom of system design also enables catering to changed requirements in the process zones with targeted selected configurations. Moreover, easy accessibility via the hinged or retractable housing enables extreme versatility for product changes, with high availability.

Therefore and due to the widely supported BUSS process expertise, many raw materials manufacturers and also the global technology leaders in this sector have placed their trust in the BUSS Co-Kneader system for masterbatch processing.

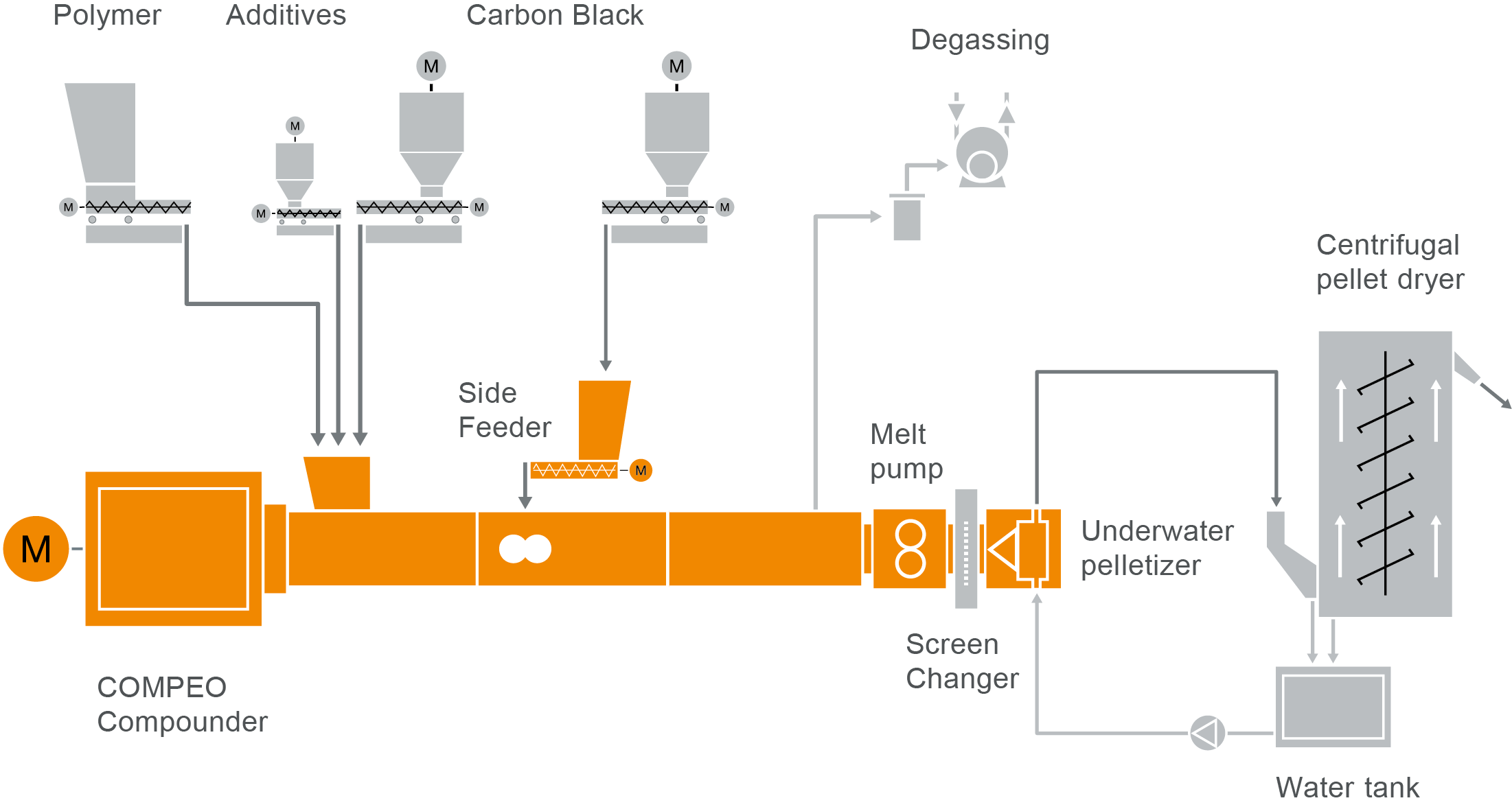

Typical plant layout

Black masterbatch

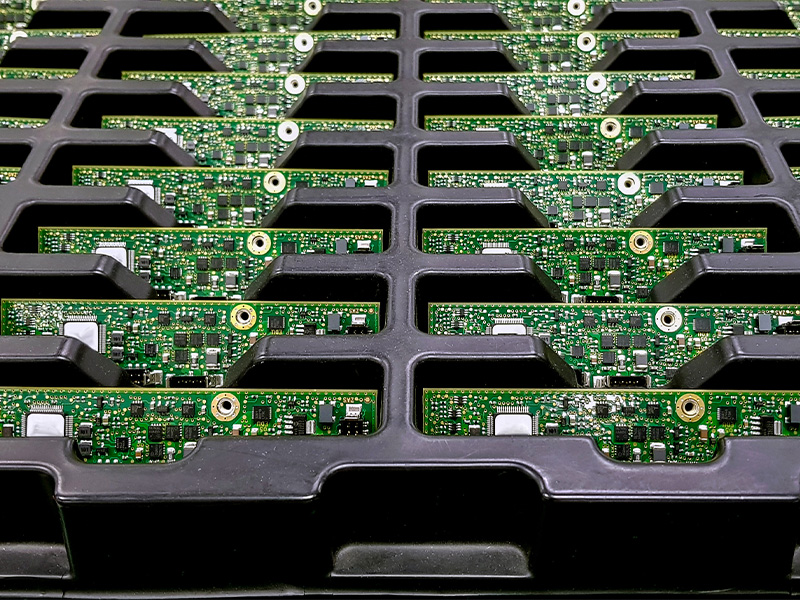

The compounding of black masterbatches or black concentrates is a typical mono masterbatch using the split-feed process. 30-50 percent carbon black is added to the basic polymer or a wax-like carrier. Carbon black, usually from furnace processing, has a large surface area, low bulk weight and typical moisture.

These properties basically define the challenges for compounding: the carbon black particles tend to form aggregates or agglomerates, which must be crushed.

Additive masterbatch

The compounding of additive masterbatches is an extremely wide field, just as wide-ranging as the variety of additives used and their effects. Specific end-product properties or application areas are realized in this way.

These typically include UV radiation protection, antistatic, antiblock, lubricant or flame retardant MB. The huge scope of requirements, ranging from high loads and varying aggregate additive conditions to shear and temperature-sensitive start and finished products, requires a universally applicable system.

Filler masterbatch

The compounding of filler MB is a special field in masterbatch production. Fillers usually exist in powder form, which should exist with high content in the MB (loading up to >80%).

Due to the bulk weight, the grain size distribution and further bulk goods properties, they can be awkward to handle or require special measures or masterbatch compounders.

The filler MB can be processed like “normal” granulate in the application and thinned down to the desired filler content in the end product.

Plant configuration with COMPEO compounder for masterbatch production

Take a look at our typical plant layout for a masterbatch compounding system in our COMPEO showroom.

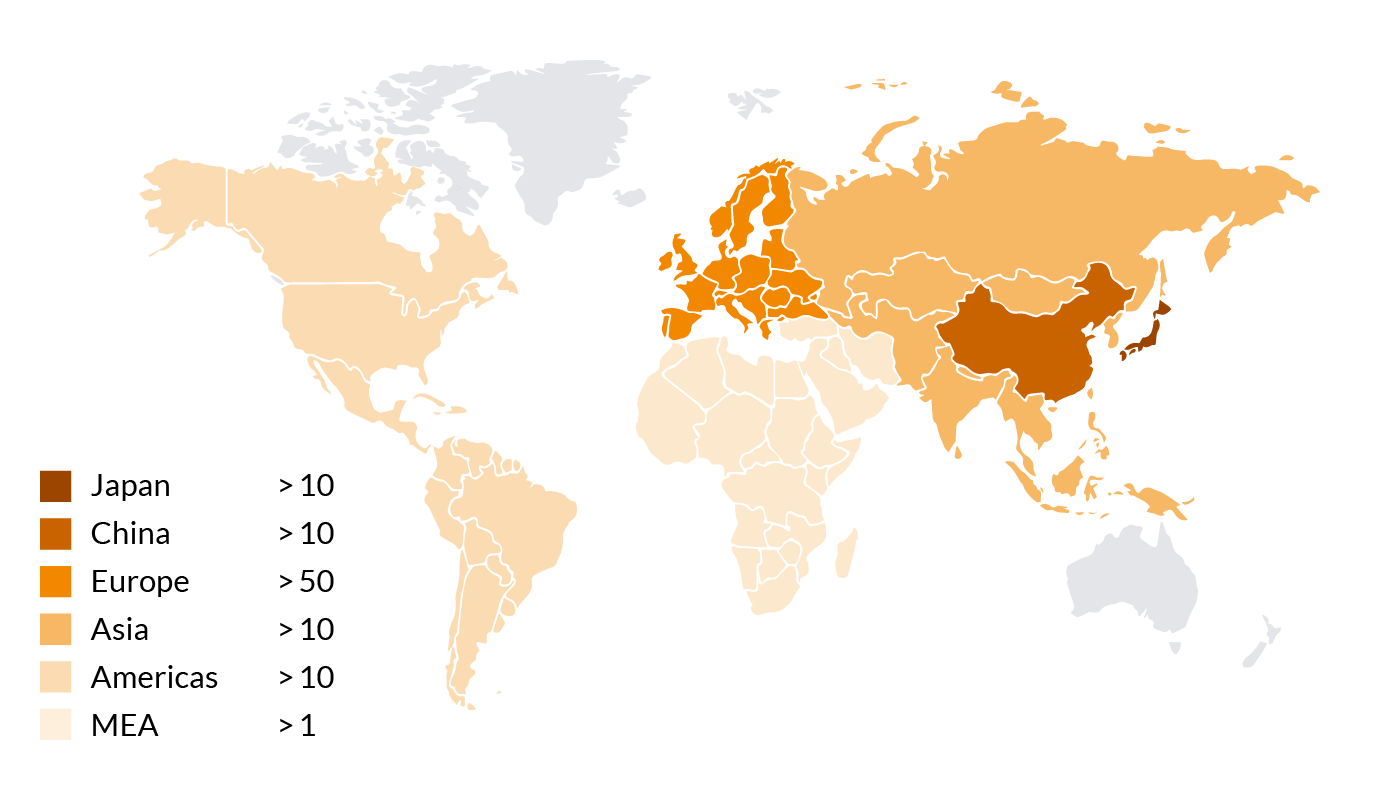

BUSS Co-Kneadersworldwide

Our patented Co-Kneaders are used worldwide nowadays, supporting our customers in plastics production. With BUSS compounding machines, our customers can master all the demanding requirements for manufacturing masterbatch compounds.

Number of Co-Kneaders used for masterbatch compounding