The term LVT stands for Luxury Vinyl Tiles. These are floor tiles on a vinyl or PVC basis. They consist of several layers – one of which is the so-called “decor layer”. The decor layer is printed, providing virtually unlimited design and color options. Thus, you can hardly distinguish wood, ceramics and stone decors from the original.

Typical areas of application

Special embossing technology ensures a corresponding haptic result. They have an installation height of only a few millimetres, can be laid directly on a prepared backing and are known to be particularly low-maintenance.

Due to the vinyl basis and the opportunity to integrate considerable recycling fractions, the products have a low CO2 footprint and a good energy balance.

These outstanding properties have made LVT a much valued flooring in the living area, business area and also public buildings . This is accompanied by exceptionally high growth rates and continuously optimized manufacturing methods derived from them.

Benefits

The advantages of BUSS compounding technology for processing LVT compounds

Compounding requirementsfor luxury vinyl tiles (LVT)

In order to achieve the special properties of LVT, the floor covering is composed of several special layers. This takes place classically with separate manufacturing of the compounds on BUSS Kneaders and respective calendering processes. The individual layers are compacted in the following process.

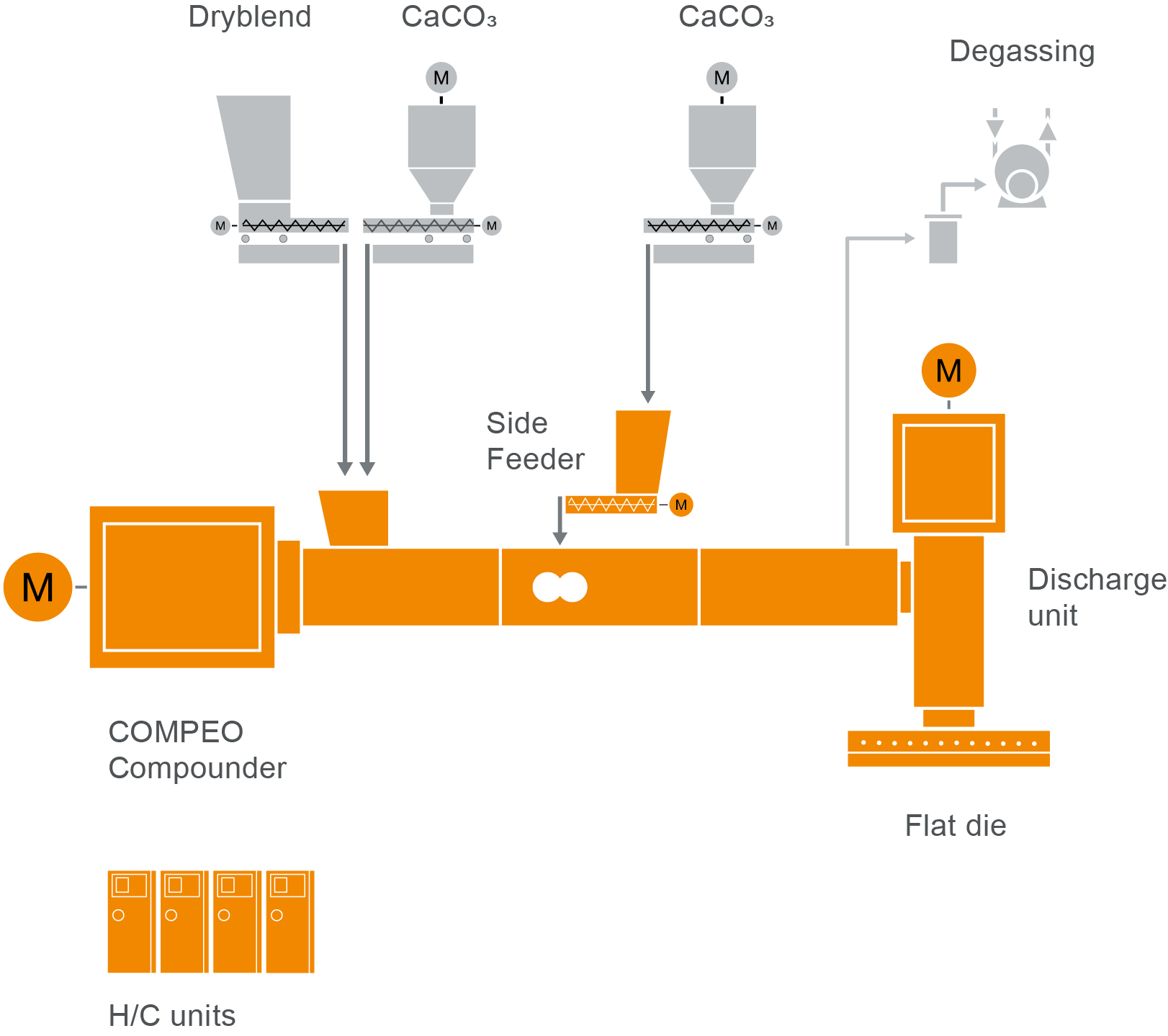

In the optimized process, the three-layer core layer of the floor covering is then manufactured using two extruders and two calenders. In the first BUSS Kneader a PVC compound, to which a high proportion of mineral fillers and other additives are fed with the help of the side feeders and split-feed, is plasticized and homogenised. The pressure build-up for feeding a flat film die is realised by a flange-mounted discharge extruder, thus securing the compounder stage decoupling.

In the following first calender, the compound is applied to the fiberglass mat. This composite material is guided into the second calender where the PVC mixture processed in the second BUSS Kneader is applied to the other side of the fiberglass mat. The inline processing, compounding and plate manufacture at a constant temperature is the great advantage of this process: the thermally sensitive material PVC is treated gently and intermediate cooling and heating steps are redundant. After the second calender, the decor and wear-resistant, protective layer are laminated on the three-layer core material.

Then the 5-layer composite runs through an embossing station and a tempering stretch and is finally cut to measure.

Thus, it became possible to address specific requirements with BUSS process expertise and the continuously improved strength profile of the BUSS Kneader: optimum product properties are achieved at uniform, moderate and adjustable shear speeds as required with intense mixing procedures. Molding via the wide slot die allows the use of calendering technology for economical direct processing. Using the technology features described demonstrates why BUSS has always been the technology and market leader in processing vinyl-based materials.

Typical plant layout

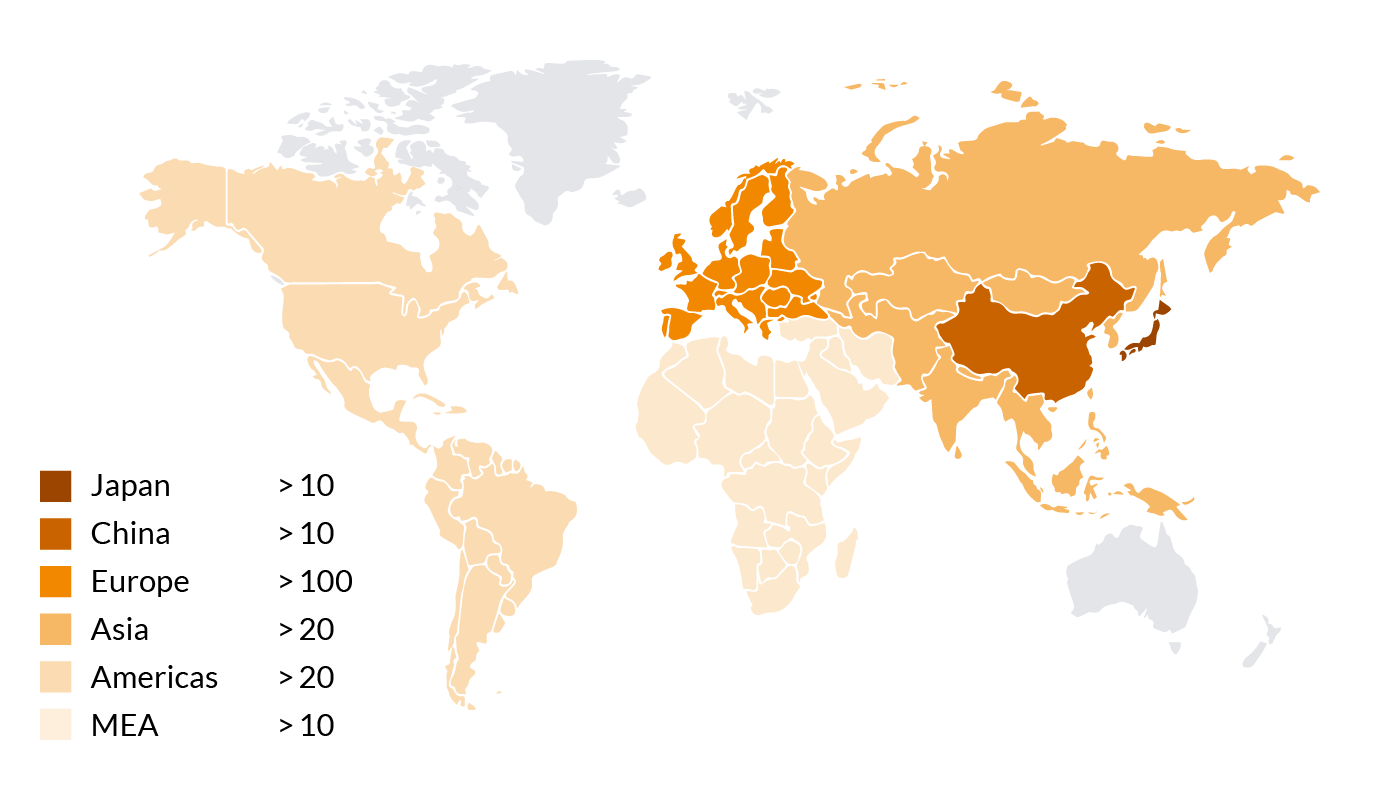

BUSS Co-Kneadersworldwide

Our patented kneaders in operation worldwide today support our customers in plastics production. Our customers can handle all the demanding requirements of PVC compounding using the BUSS compounding lines.

Number of BUSS Kneaders used for calender compounding