Nowadays we assume that the first adhesive used by mankind was a hot melt: already at least 45,000 years ago, birch pitch was used to join stone and wood for weapons and tools. The different hot melts range from pressure-sensitive hot melt (PSHM) or hot-applied hot melt (HAHM) to UV or heat-activated, reactive hot melts.

Vis-à-vis classical adhesives, hot melts score with various features: the products can be processed fast and receive the respective properties when they cool off without hardening for solvent-based or 2-component systems. Widely differing materials and surfaces can be safely joined. Moreover the adhesive joint has a certain elasticity. These special properties require specialized hot melt compounder systems nowadays.

Typical areas of application

These materials thus became well-established in many applications due to their specific properties. These include, for example, hot melt or fusible adhesive applications in the packaging industry where different carriers are coated with hot melts.

In the clothing, textile and shoe industries, the correspondingly glued connections resist high loads when in use or during cleaning. In electrotechnology, assemblies are similarly fixed using it, protected by partial potting and also with extended functionality. Numerous further applications are known – last not least in the DIY sector.

Benefits

BUSS compounding systems offer the following specific benefits

Compounding requirementsfor hot melts

Due to the properties and functions described above, hot melts have become sophisticated high-tech compounds which are constantly developed further and applied to develop new applications. The BUSS Co-Keader and BUSS compounding system have been used extremely successfully in the various product classes for many decades.

The handling and feeding of formulation components such as polymers, resins, plasticizers and additives in different aggregate states and with different viscosities, as well as fillers and reinforcing materials, are highly significant for the compounding process.

The excellent dispersive and distributive mixing processes at moderate shear rates and adjustable product temperatures are the decisive success factors for achieving the desired property profiles.

The BUSS Co-Kneader’s specific capabilities are clearly demonstrated in these applications: Due to the operating principle, the enormous number of mixing cycles at moderate and adjustable shear rates enables unsurpassed mixing efficiency over short process lengths with narrow residence timeframes.

Degassing processes ensure that no air or volatile accompanying substances remain in the product. With the BUSS Co-Kneader two-stage system, compounding and the pressure build-up step are strictly decoupled. This enables optimization of the process steps independently of each other and the pressure build-up device can feed any subsequent direct processing.

Batch processes still play an important role in the manufacturing of hot melts. The extended requirements for today’s and tomorrow’s products such as constant quality, traceability and system availability are often met ideally by continuous processes.

The modular and correspondingly adaptable structure of the entire line and the widely supported BUSS process expertise in compounding – also with regard to the changeover from batch processing to continuous processes make the BUSS system an excellent choice for compounding hot melts.

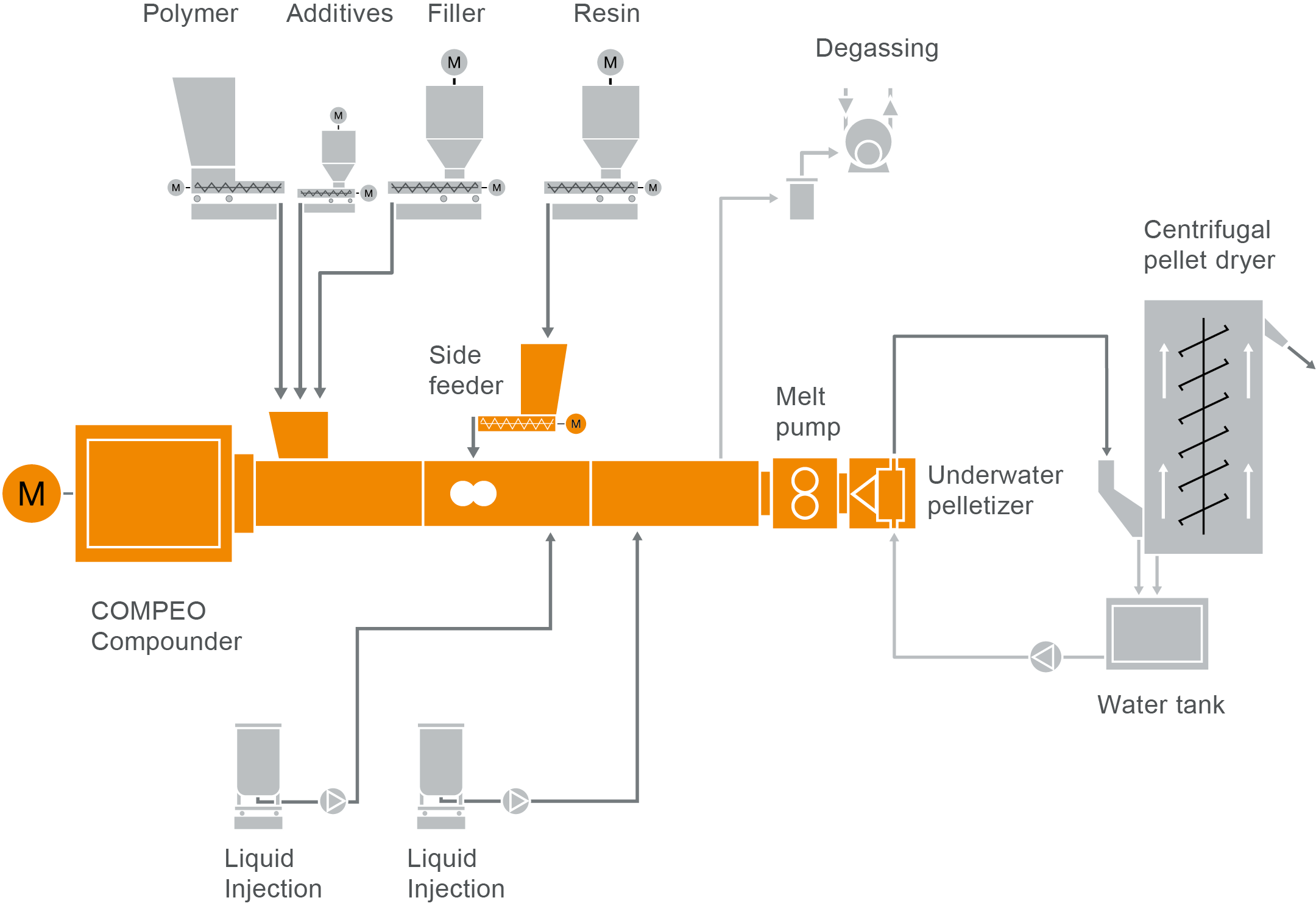

Typical plant layout

COMPEO showroom video plant layout

Find out more about the setup of a plant layout as is typically used when hot melt is produced using our COMPEO compounders.