Compared to other materials, plastics have several advantages. However, they cannot be taken advantage of in certain application fields due to lacking conductivity.

In particular in potentially explosive areas, when packaging and handling electronic components or also when transferring radio signals, the lacking conductivity may result in failure or considerable functional impairment. The danger of electrostatic charging exists.

If materials charged in this manner discharge via spark formation, they can ignite explosive atmospheres such as solvent/air mixes or dust/air mixes. This type of plastics cannot be used for such applications.

Typical areas of application

In order to nonetheless use the advantages of these plastics, special conductive additives are added to them. This increases their conductivity considerably or reduces their electrical resistance considerably.

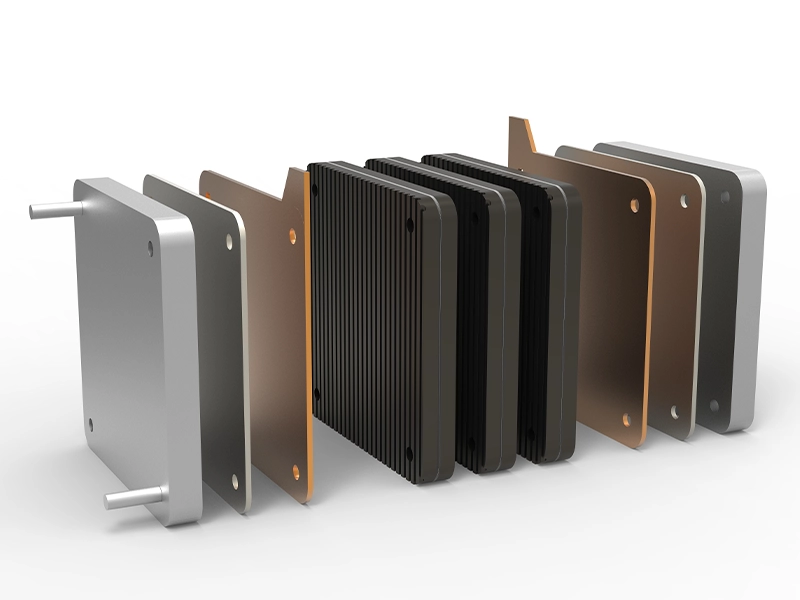

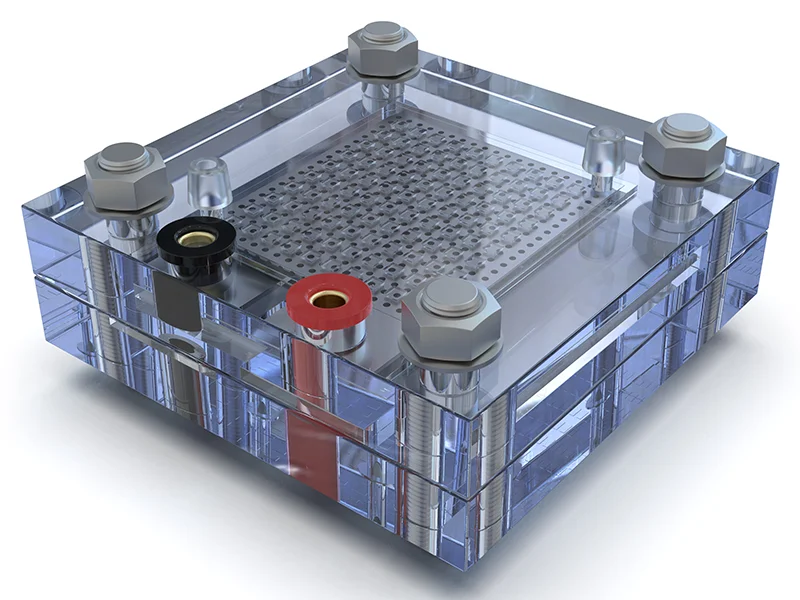

For example, this measure can reduce the electrical contact resistance of PE from 1016 Ohms to < 104 Ohms. The plastics become electrically conductive. If grounded, electrostatic charging can be safely avoided. In fuel cells, for example, highly conductive compounds are used as material for the bipolar plates.

Benefits

BUSS compounding systems for highly conductive compounds offer the following specific benefits

Compounding requirementsof highly conductive plastics

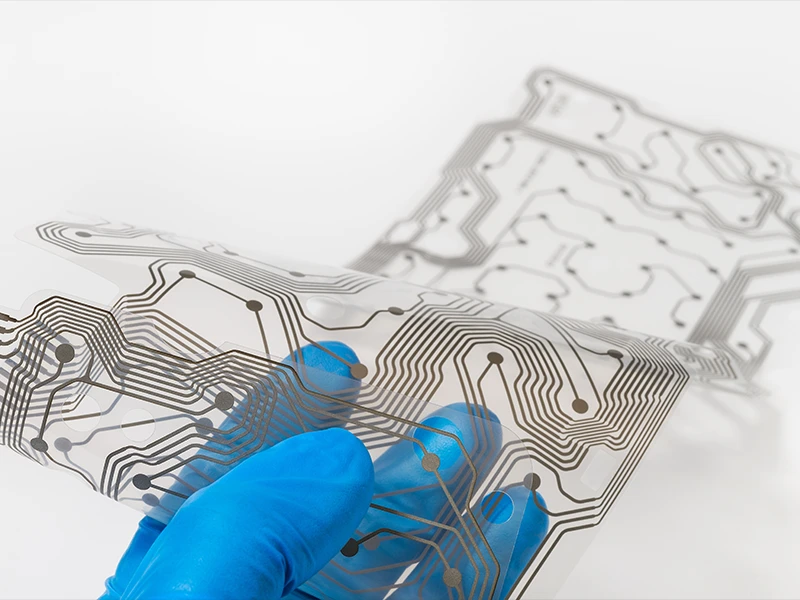

These specific property profiles are achieved in the compounding step. The processing requirements are very demanding. The conductivity values must be guaranteed both at room temperatures and increased operating values.

The highly-structured carbon black, graphite, carbon nanotubes and carbon fibers must retain their structure and be distributed extremely homogeneously in order to form the required conductive network. The polymers used may be degraded as little as possible. The ability to cross-link the compounds may also be a further requirement.

These requirements which in-part run into each other are mastered well, using sophisticated processes.

The BUSS Co-Kneader has proven itself over a long period when compounding these particularly demanding materials. The moderate and uniform, if necessary also specifically adaptable shear rates and with them precise temperature management of the BUSS Co-Kneader play the central role here: in the melting zone only as much energy as required is dissipated without overburdening the polymer components.

The conductive agents are optimally distributed within the shortest process length due to the high flap-die values. At the end of the process, the fibrous conductive materials are added, separated and wrapped if necessary in order to maintain the maximum fiber lengths and to ensure the corresponding properties in the conductive network. This also enables the achievement optimum property profiles for the narrowest processing windows and highest viscosities.

With the two-stage system of the BUSS Co-Kneader, compounding and the pressure build-up step are strictly decoupled. This enables independent optimization of the process steps. The hinged BUSS Co-Kneader housing assures fast access and high system availability.

The modular and therefore adaptable plant structure and the widely supported BUSS process expertise make the BUSS Co-Kneader a very good choice for compounding demanding highly conductive compounds and provide top investment security.

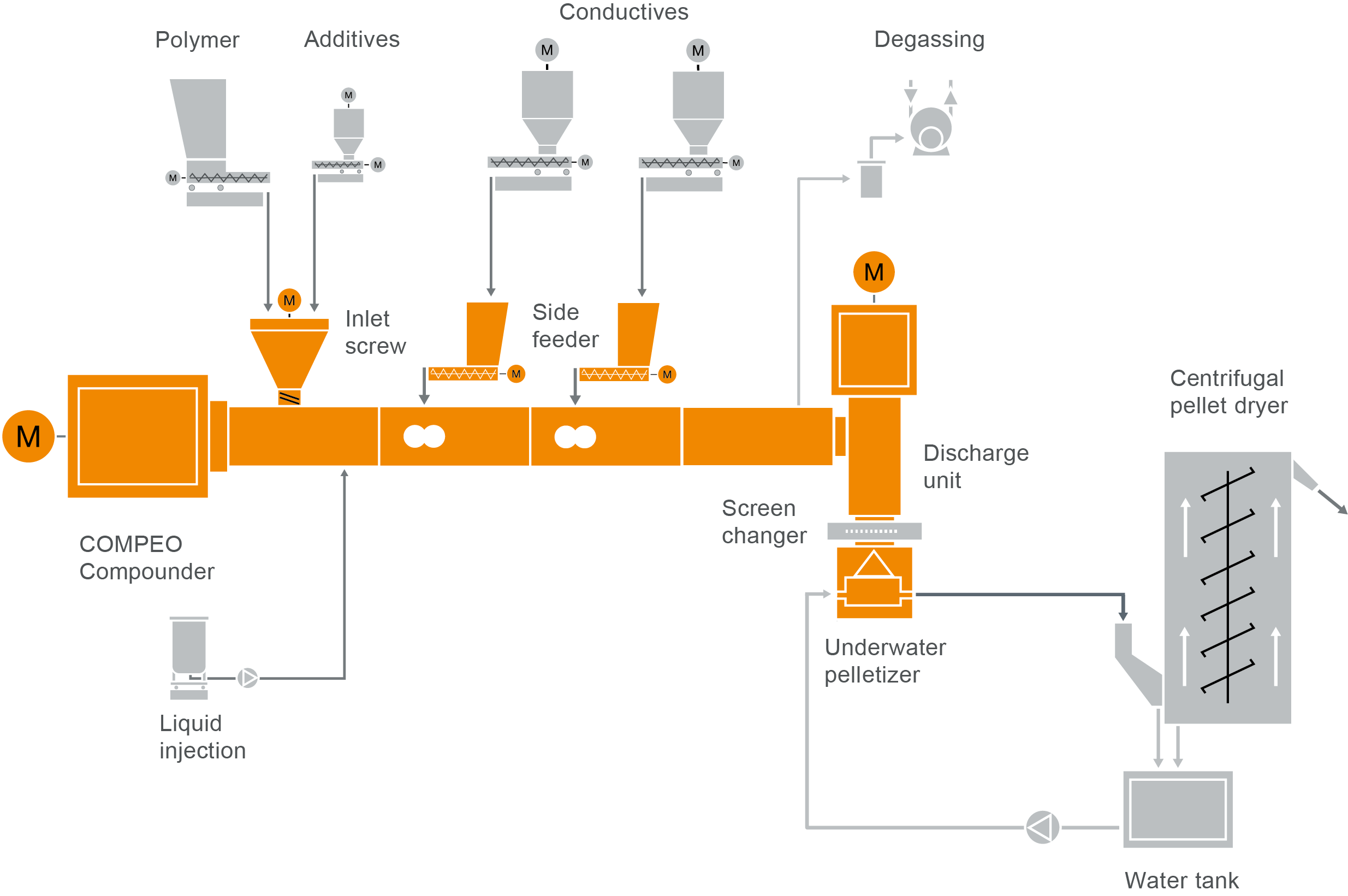

Typical plant layout

COMPEO compounder for compounding highly conductive compounds

Take a look at our typical plant layout for the production of highly conductive compounds in our COMPEO showroom.