Fluoropolymers belong without any doubts to the high-performance polymers. The polymer polytetrafluoroethylene (PTFE) was discovered by chance by Plunkett at DuPont in 1938. The exceptional properties of fluoropolymers were quickly recognized and are still decisive for several high-tech applications today.

In addition to exceptionally good chemical resistance, they possess excellent chemical and thermal properties, are resistant to wetting and non-flammable, and exhibit extremely low friction coefficients. Most of these properties can be attributed to the existing fluorine atoms.

Fluorine is the most electronegative and reactive non-metal in the periodic table. Following hydrogen, fluorine has the smallest atom radius of the elements. When it reacts with carbon, an extremely short and strong bonding is formed, which determines the exceptional properties of the fluoropolymers. The closure of the product cycle for fluoropolymers enables up-cycling, also for end-of-life products.

Typical areas of application

The fluoropolymers can be split to the following sub-groups: the PTFE share is some 66% of the overall volume: due to its high melt viscosity, PTFE cannot be processed thermoplastically. The fluorothermoplastics such as PVDF, PFA, FEP, etc. comprise some 28% of the volume. The wide-ranging product group of fluorine rubbers (FKM), which includes both the so-called biopolymers and the terpolymers forms the third sub-group with a total of 8%.

Both last-named product groups are customized for specific applications during the compounding step. Additives containing PTFE can play a role in applications such as slide bearings.

The combination of technical process expertise, the system-specific BUSS Co-Kneader options as well as the knowledge of the metallurgic configuration of the lines allows the implementation of sophisticated solutions: this ranges from different content of conductive additives via production in the cleanroom for medical applications to the reinforcement with glass and carbon fibres for highest mechanical demands.

Benefits

BUSS compounding systems offer the following specific benefits when preparing fluoropolymers

Compounding requirementsof fluoropolymers

The immediately effective, gentle mixing processes and respective relaxation phases lead to excellent distributive mixing results, with optimum maintenance of the inner structure of the conductive materials or length of the fibers. The moderate BUSS Co-Kneader shear rates secure running in the permissible operation window without temperature peaks, which could cause the splitting-off of hazardous side-products with alternative systems.

The freedom of system design also enables specific responses to the increasing viscosity in the process zones with specifically selected configurations to be taken into account. This allows customized management and control of the process conditions. Moreover, the compounding and pressure build-up steps are strictly decoupled in the two-step BUSS Co-Kneader system.

Thus, the preparation step is optimized for the best possible results pertaining to quality and throughput, independent of pressure build-up, filtration and molding step.

The Co-Kneader compounding technology used makes BUSS a technology leader and an ideal partner for the development and commercialization of sustainable system solutions.

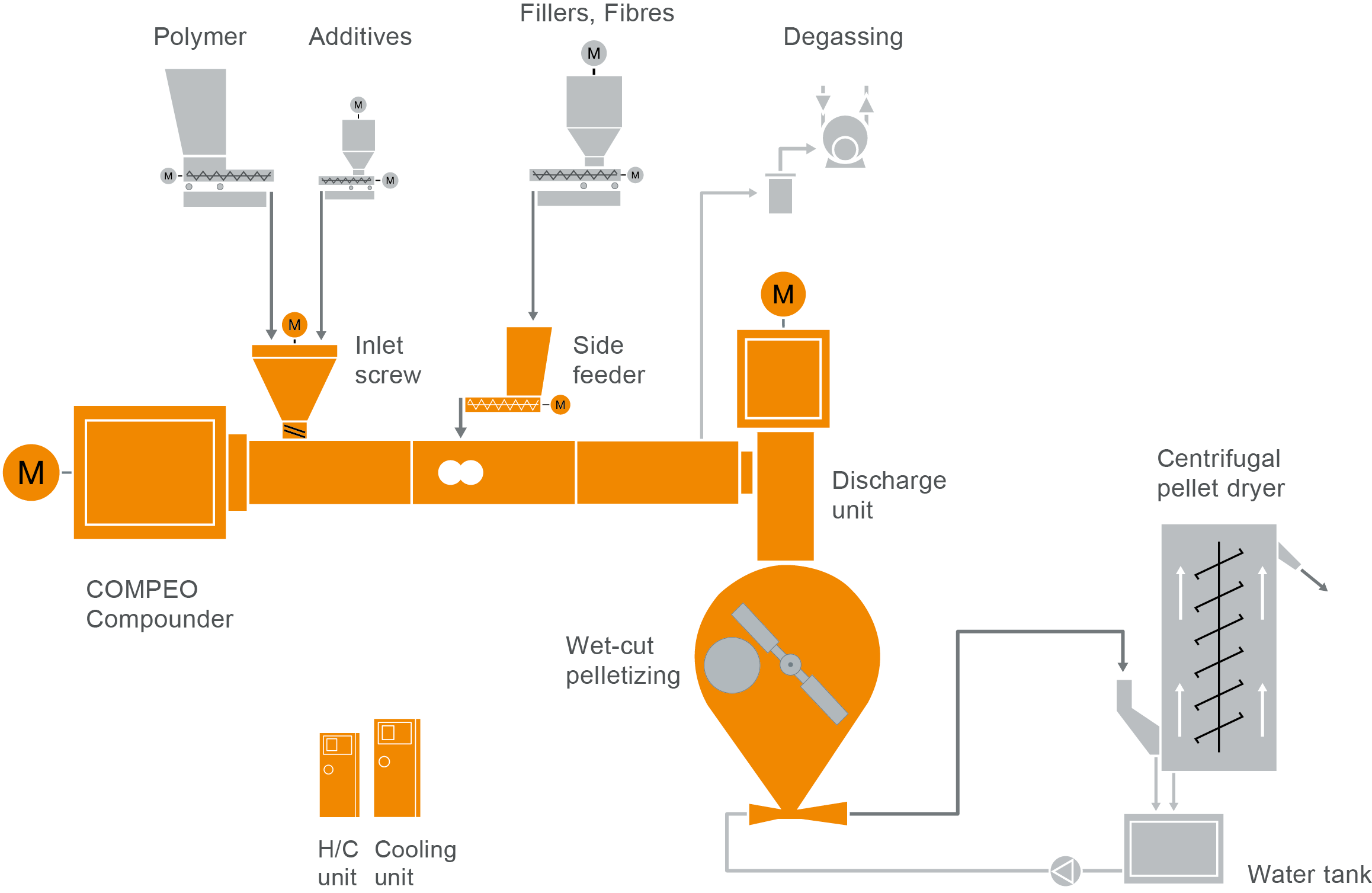

Typical plant layout