Epoxy molding compounds have been known for their good electrical and mechanical properties as well as their excellent chemical and aging resistance for a long time. The first descriptions and patents originate from the 1930s.

The epoxy resin molding compound consists of a polymer matrix (epoxy resins, hardeners and accelerator catalysts) which is mixed with fillers, reinforcement materials, pigments, separating agents, etc. and molded as granulates/chips.

Typical areas of application

Epoxy resin molding compounds react in a polyaddition reaction, i.e. no side products arise when molding. Therefore, independent of the type of molded part, identical final properties are achieved, independent of the wall thickness.

If the reaction in the mold is completed, no further changes to the mechanical, electrical or thermal properties take place. Re-hardening is not necessary and reaction-caused post-molding is virtually non-existent. This is also one of the reasons for the outstanding long-term stability of epoxy molding compounds.

Therefore, they meet demanding requirements profiles for diverse applications in electronics, medical technology and the automotive industry. With the ongoing progressing miniaturization of electrical components and their simultaneously increasing performance, the requirements of an insulating coating system which protects against environmental influence are further increased.

Thus, for example, they must withstand numerous sterilisation processes for medical technology without damage and demonstrate a high degree of resistance against X-rays.

Benefits

BUSS compounding systems offer the following specific benefits for epoxy resin preparation

Compounding requirementsof epoxy resin molding compounds

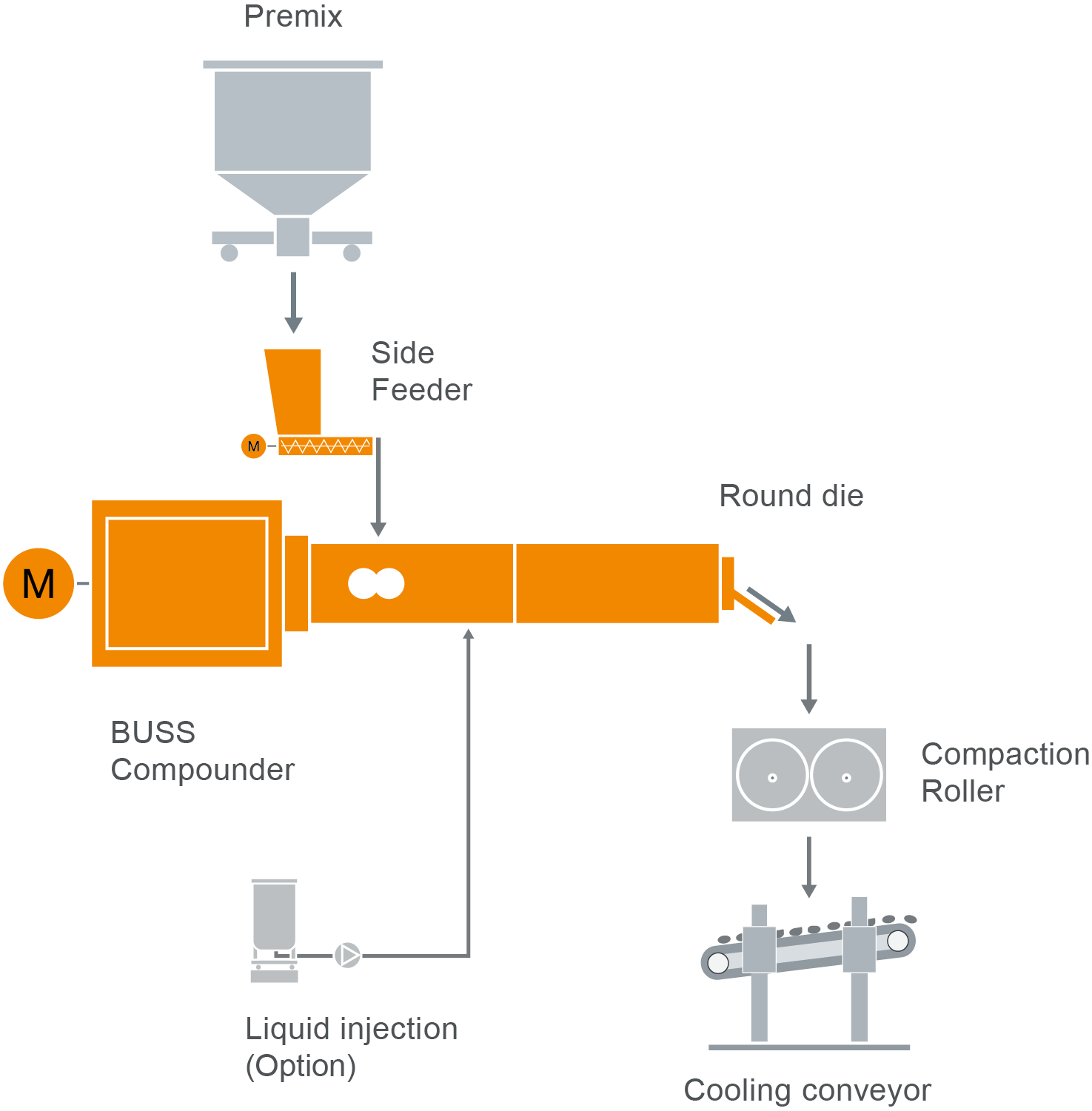

In addition to the gentle integration of the high content of additives, the central requirement in the preparation step for epoxy resin molding compounds is the adherence to the temperature limit below the cross-linking temperature. This succeeds with the BUSS Co-Kneader due to its working principle, during which a relaxation sequence follows each gentle shear cycle in an excellent manner.

Optimal process temperatures can be monitored at any time due to exact measurement of the product temperature via drilled kneading pins. This data can also be used as a proof of quality assurance. Customized material solutions are responsible for above-average service life in the process room.

The economical throughputs and all the advantages of the continuous production means such as extremely constant and traceable product quality, a high degree of utilization and availability of the machines round off the excellent suitability of the BUSS Co-Kneader technology. Augmented with the widely supported BUSS process expertise, the BUSS Co-Kneader is first choice for the continuous compounding of epoxy molding compounds.

Typical plant layout

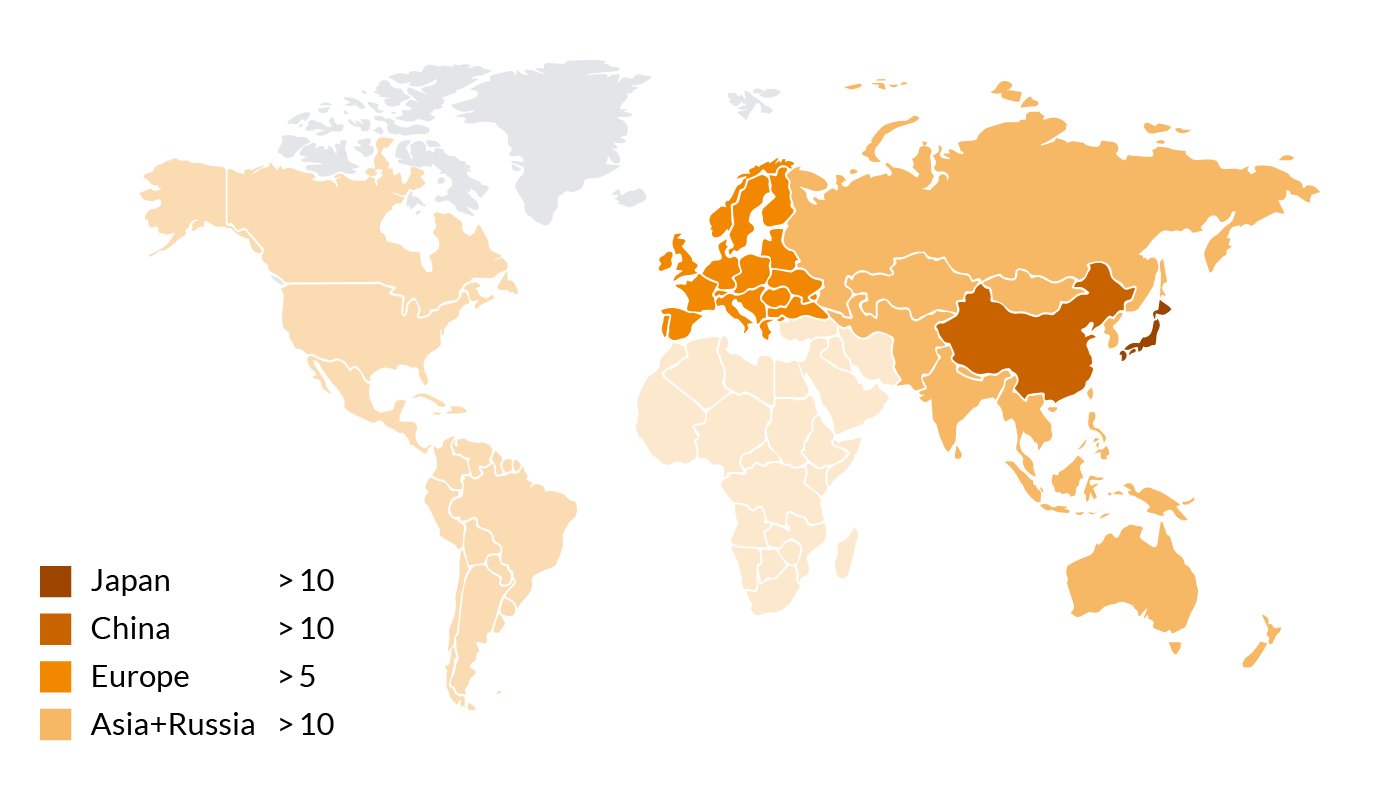

BUSS Co-Kneadersworldwide

Our patented Co-Kneaders are used worldwide nowadays, supporting our customers in the production of plastics. Using the BUSS compounding systems, our customers can master all the demanding requirements for epoxy resin compounding.

Number of Co-Kneaders used for EMC compounding