BUSS has more than 50 years of experience in calender feeding. BUSS Kneader technology provides huge advantages, in particular when processing PVC for manufacturing foils, films and plates in the most varied of widths and thicknesses.

Calendering is understood as the manufacturing of films and foils from plastics such as PE, PET or PVC, from rubber, metals and paper. Calender feeding is a system with several heated and polished rollers consisting of chill casting or steel through whose gaps, a pre-plasticized molding material from a BUSS Kneader or other materials is fed. In this way, the material is finally homogenised, plasticized and brought to the required thickness.

After calendering, the product is consolidated on cooling rolls. We distinguish between melt calendering for film and semi-finished foil products and coating calendering, for example for coating fabric (conveyor belts). When calendering, it is also possible to emboss, smoothen, compress or bead glaze. Equally, polymer fleeces can also be bonded to form nonwovens. The designation of calender designs (L-, F-, I and Z form) relates to the arrangement of the rollers.

Typical application areas

The rigid PVC film and semi-finished foil products have a wide range of application fields. For example: hard film for the packaging of medical devices, which allow various sterilization, barrier and sealing processes, card products for finance, keys, identification applications, furniture films and foils, printable label and signage applications.

Flexible film and semi-finished foil products are also used in a wide range of applications: a prominent example is flexible foil/film for blood and transfusion bags used for medical applications. Due to the excellent resistance to chemicals, protective clothing from calendered flexible PVC film or foil is manufactured using BUSS compounders. In the building sector, corresponding foils and films used for sealing purposes, also withstand extreme burdens. Last but not least, they are used widely for the most varied types of floor coverings, printed with a single or several layers, sealed, etc.

Benefits

The advantages of BUSS compounding technology for rigid PVC processing

Compounding requirementsCalender compounding

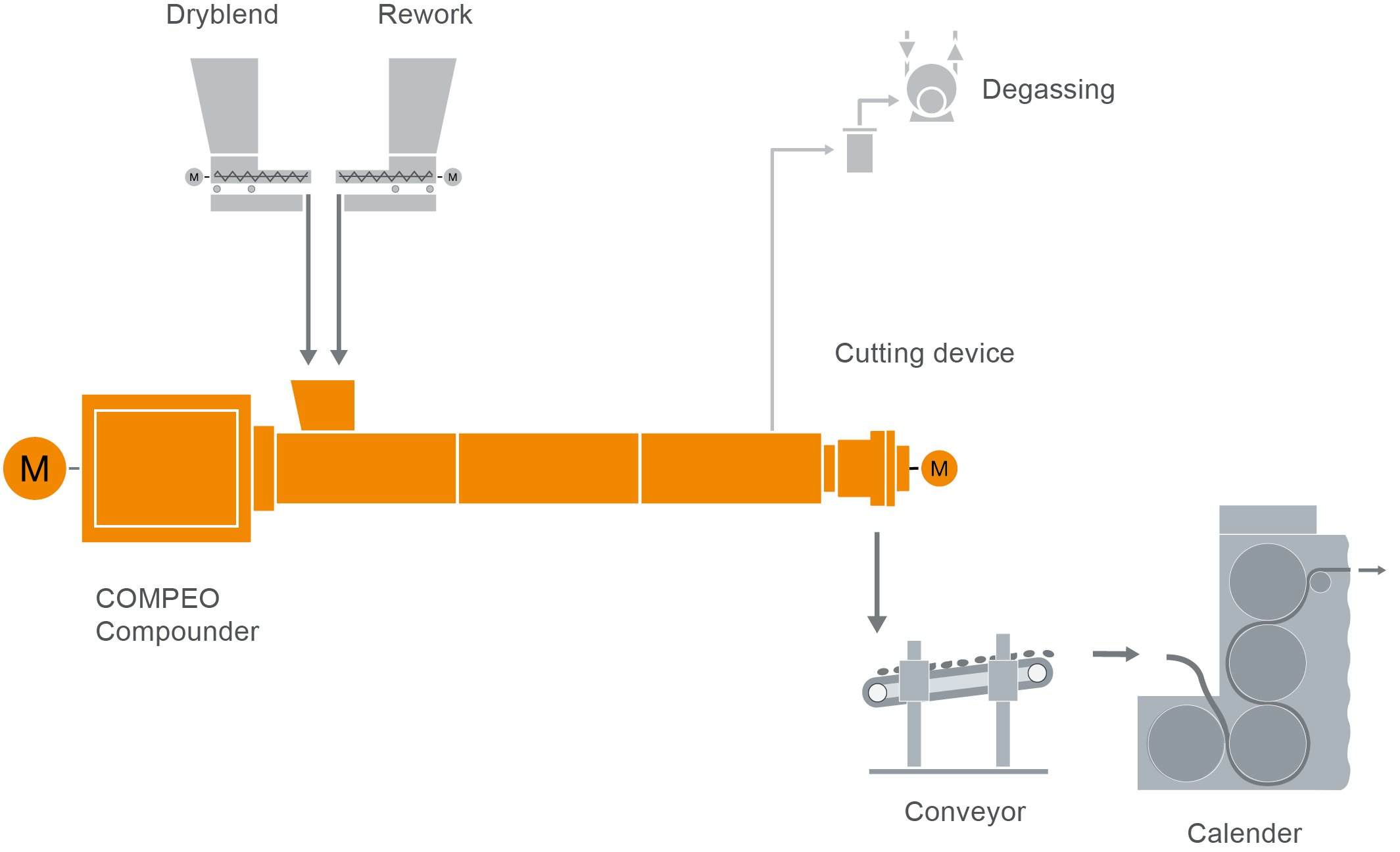

The preparation of calender mass is classically direct processing. The raw materials for the formulation are thermally compounded either as primary material or as an end product.

The following process steps are realised: the components are weighed-in and premixed during the solid phase. The powder mixture and in many cases also recycled material such as edge trimmings are dosed to the BUSS Kneader and compounded during the melt phase. At the outlet of the BUSS Kneader, the melt is fed to the calender either directly as a melt strand or as cut melt pieces.

The BUSS Kneader has the task of feeding the compounded melt in a constant, well-defined narrow temperature range with corresponding viscosity to the calender over the entire throughput area. Normally, this throughput range incorporates values from 1:3 to 1:5, but can reach up to 1:7.

Fast product changes and the degassing of volatile substances are further requirements. Thanks to its adjustable shear rate level and close distribution without shear peaks, these tasks can be resolved excellently on the BUSS Kneader. The robust operation window allows a very wide range of formulations with a single shaft geometry. For extreme color changes or when changing to transparent recipes, simply opening the process zone enables short standstill periods and maximum availability. These are just some of the advantages of BUSS calender feed.

The single-stage concept, robust design and ingenious scaling, which does not rely solely on heat transfer surfaces, have made the BUSS Kneader the technology leader for several decades. The modular and therefore adaptable structure of the entire line together with the widely supported BUSS process and MSR expertise therefore make the system best choice for calender feed with rigid PVC materials.

Typical plant layout

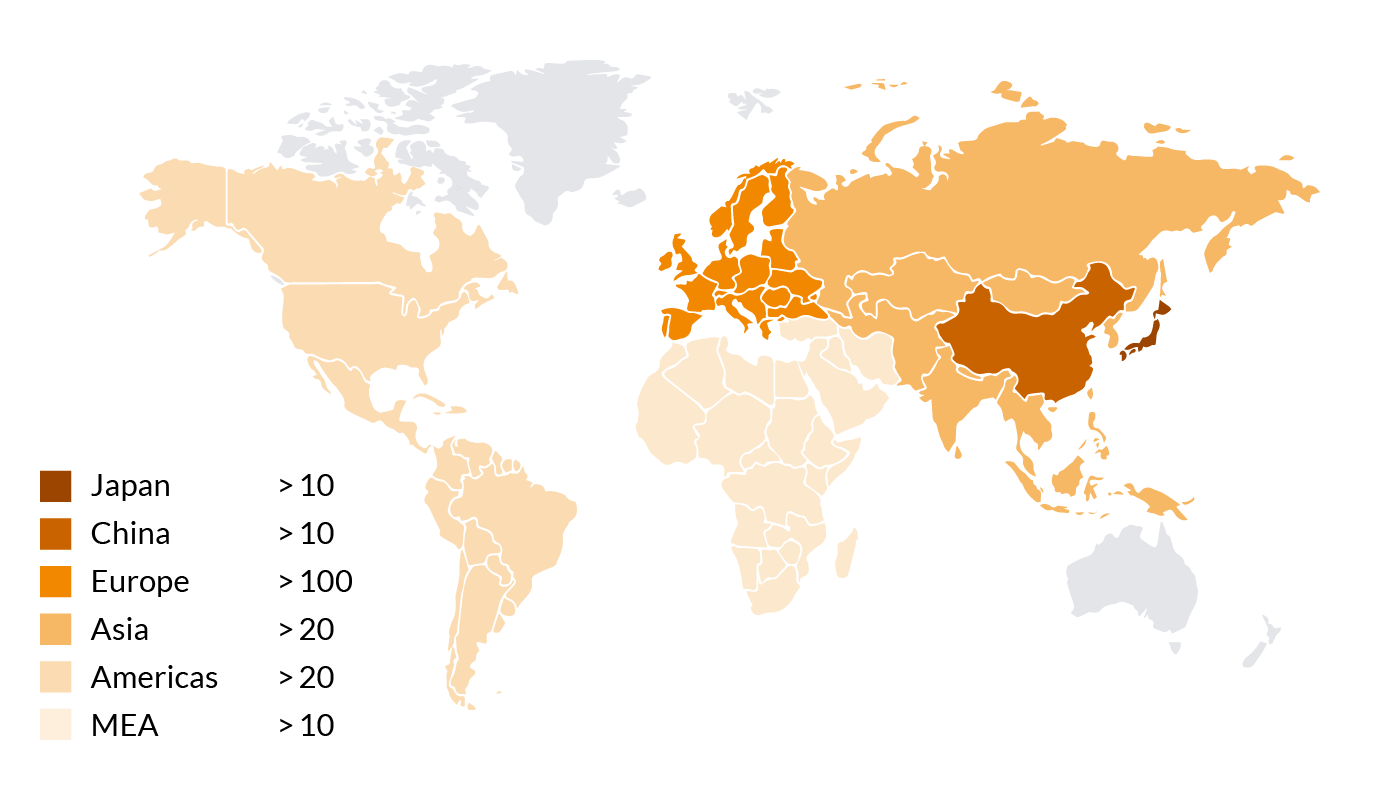

BUSS Co-Kneadersworldwide

BUSS Kneaders are represented worldwide today to support our customers in plastics production. BUSS compounding lines enable them to handle all the demanding requirements of calender feed.

Number of BUSS Kneaders used for calendar compounding

Discover more...

Luxury Vinyl Tiles

In order to achieve these specific LVT properties, the floor covering is composed of several special layers. This is done classically by separate manufacturing of the compounds using BUSS Kneaders and corresponding calendering processes. The respective layers are compacted in the following process.