In chemical terms, bitumen is the semi-solid to spring-hard, fusible, high-molecular hydrocarbon mixtures obtained during the gentle processing of crude oils and the carbon disulphide-soluble components of natural asphalts as well as earth and montan waxes.

Bitumen is a thermoplastic material, this means that its viscosity is temperature-dependent: when heated, it passes continuously through all states from solid to viscous until it becomes thin between 150 °C and 200 °C.

Thanks to finds in the Middle East, applications can be traced back to before antiquity. In the 19th century, production methods for the continuous extraction of bitumen became possible. Today, it is mainly obtained as a residue from the vacuum distillation of crude oil. Depending on the desired quality, a specific property profile is set by mixing with heavy vacuum gas oil.

Typical areas of application

Bitumen plays an important role as a carrier matrix in several applications. Here, properties such as sealing capability, resistance to weathering, wettability and adhesion to dry surfaces are extremely important.

These are applied in diverse types of applications, including back layers of carpets and floor coverings, sound and vibration insulating heavy-duty film or foil and components in vehicles and technical installations as well as various applications in the building sector.

Benefits

BUSS compounding systems offer the following specific benefits when preparing bitumen

Compounding requirementsfor bitumen

The traditional production method for highly-filled bitumen compounds is the preparation of batch internal mixers. These established processes provide advantages such as flexibility, easy offline dosage, also for smaller formulation content as well as variable dwell and mixing times.

However, limitations such as intermediate storage times and also property fluctuations between individual lots allow continuous processes to exploit their advantages: uniform process conditions, narrow dwell time distribution and the integration of process steps belong to the typical strength profile.

The BUSS Co-Kneader can, with precise temperature management, score when handling large viscosity differences between bitumen and polymers/elastomers as well as the possibility to mix highest filler shares perfectly.

Recently, a wide range of enhanced application fields has been added: here, the integration of process steps such as inline processing on carrier substrates as well as the use of alternative formulation components play important roles. These high requirements are accommodated and implemented using sophisticated processes. The processes can be developed and optimized at the BUSS Technical Centers.

Plants with a throughput factor of 10 are realized and operate successfully. In a throughput range of 1:6, the products are processed directly inline. The hinged BUSS Co-Kneader housing also secures fast access to and high availability of the system.

The modular and therefore adaptable structure of the entire system and the widely supported BUSS process expertise make the Co-Kneader system an excellent and future-proof choice for compounding highly-filled bitumen and its future substitution materials.

Typical plant layout

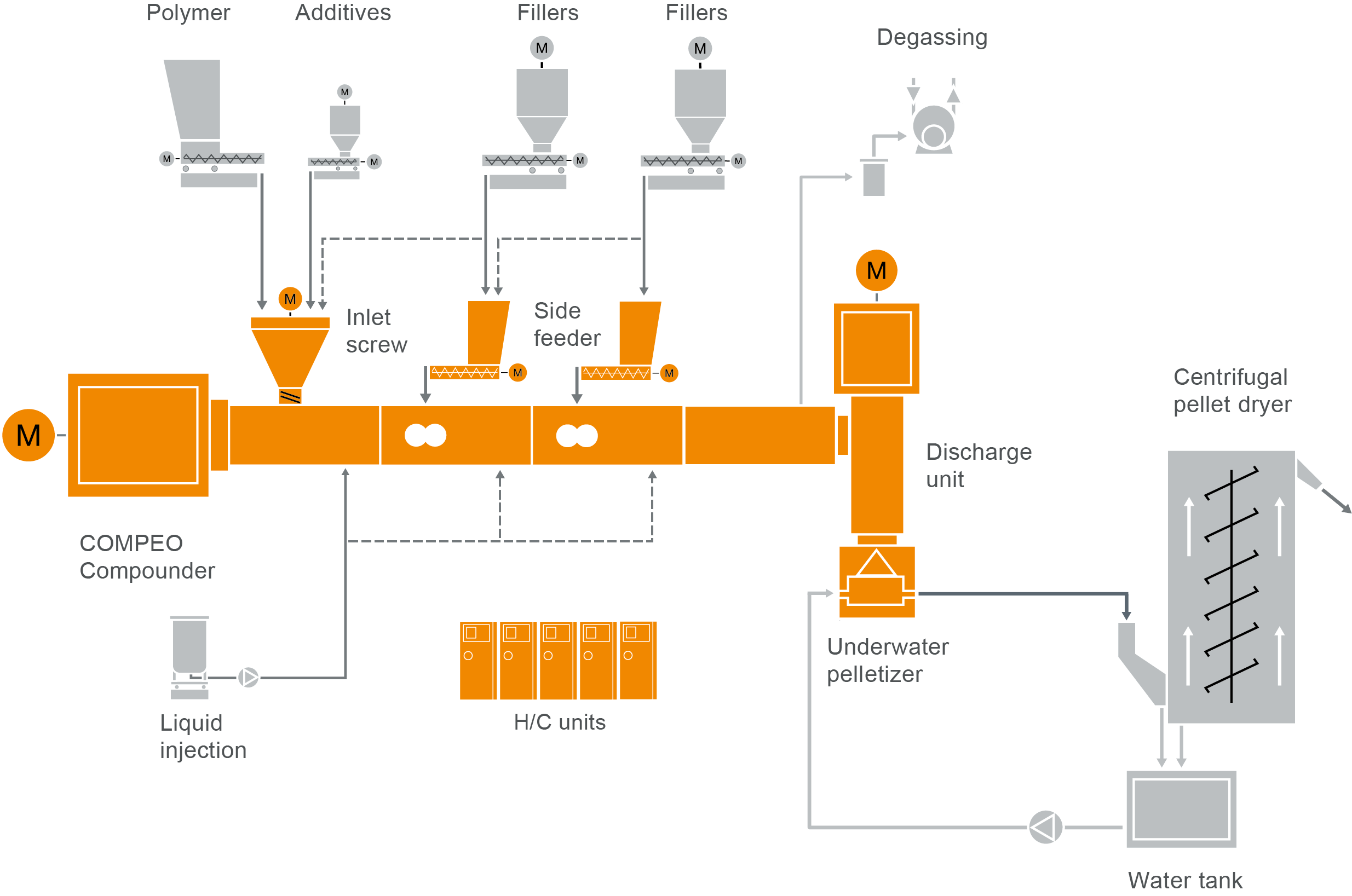

COMPEO compounding system configuration for bitumen compounding

Take a look at our typical line layout for the production of bitumen in our COMPEO showroom.