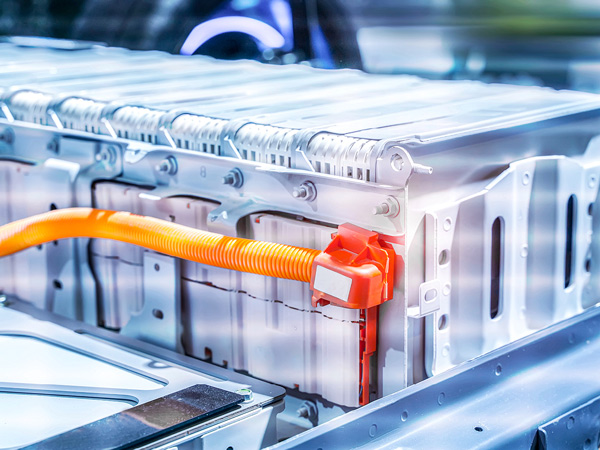

The development and realization of rechargeable battery systems with high energy density are important parts of the response to global trends as well as the UNO sustainability targets. Here, the sustainable and decentralized energy generation, storage and use of energy play a key role. In finding suitable material combinations, the handling of electrically conductive materials for anodes and cathodes gains great significance.

Typical areas of application

The typical requirements on manufacturing anodes and electrode compounds include intense mixing in solids and also during the viscous phase without destroying the structure of the functional fillers and thus reducing conductivity. At the same time, adherence to strict temperature limits is also a possible requirement.

The knowledge gained over several decades with regard to handling conductive materials, which can also be nanostructured such as graphene or various carbon nanotube (CNT) versions or otherwise in alternative industries, enables the BUSS process developers to find customized solutions, evaluate them and apply them successfully.

Thus, the full potential of continuous systems is exploited: uniform process conditions, narrow dwell time distribution, process control and assurance at all times as well as the integration of diverse process steps, belong to the features typically used.

Benefits

BUSS compounding systems offer the following specific benefits

Compounding requirementsfor battery electrode compounds

The combination of technical process expertise and the system-specific BUSS Co-Kneader options allow the implementation of sophisticated solutions: high content of conductive additives can be distributed at several feed points.

The directly starting mixing processes at moderate shear rates, and respective relaxation phases, lead to excellent distributive mixing results without damaging the inner structure of the conductive materials.

It is often possible to achieve similar electrical properties with low content of conductive components or better properties with the same content. This results in improved processability due to the lower viscosities. Moreover, the system's design flexibility enables specific response to the increasing viscosity in the process zones with specifically selected configurations.

This enables customized management and control of the processing conditions. BUSS' Co-Kneader technology and extensive process expertise make BUSS a technology leader and ideal partner for the development and commercialization of sustainable system solutions.

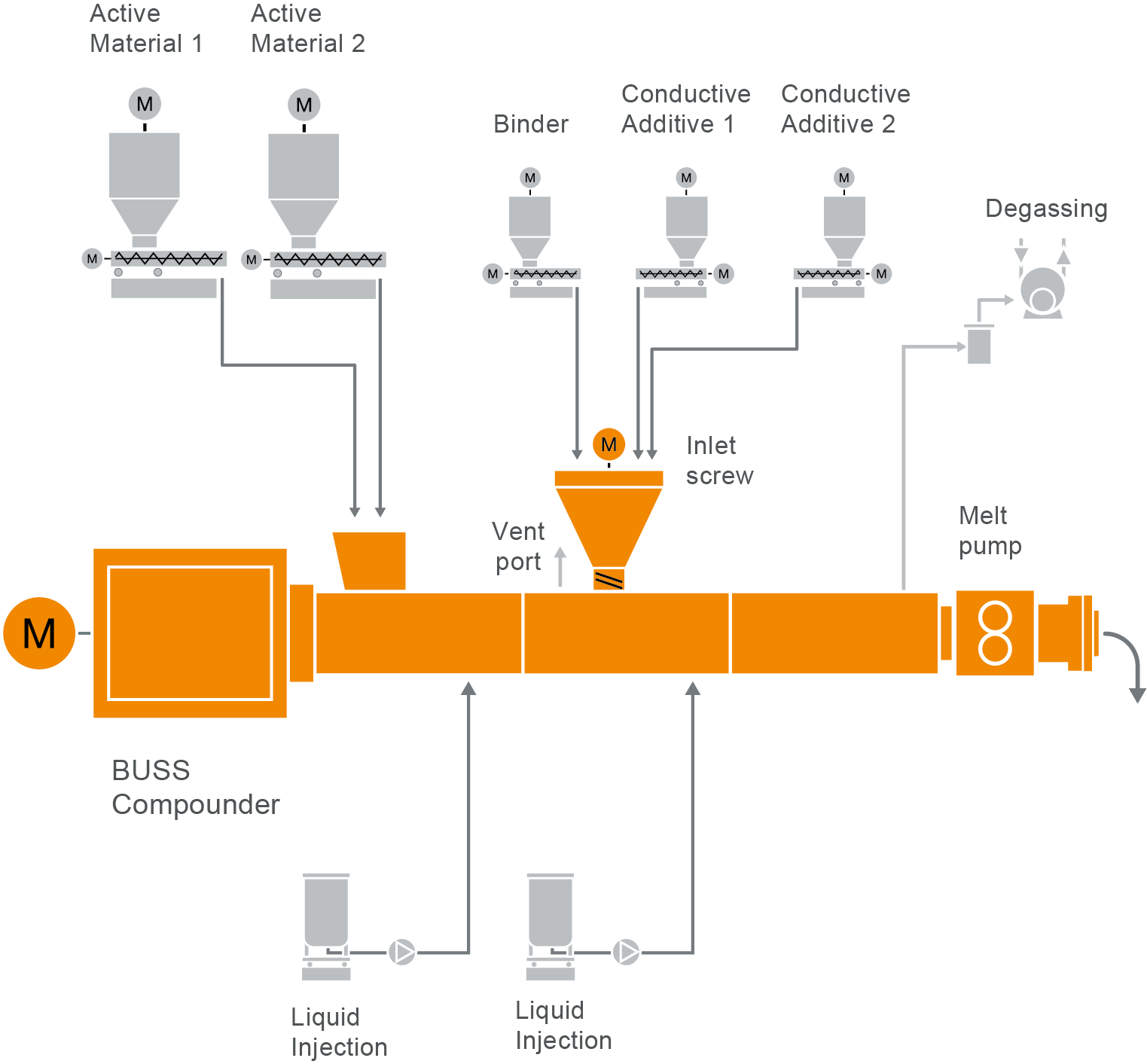

Typical plant layout

COMPEO plant layout for the compounding of anode and cathode materials

Find out more about setting up a battery mass plant layout as typically used for electrode compounds are produced using our COMPEO compounders.