The very high contact and surface resistances of polymers such as polystyrene, polycarbonates and also polyolefines have the effect that charges can only discharge slowly. The effect known as triboelectric charging, for which a one-off contact suffices to charge the surface electrostatically, has the consequence that components often come out of the shaping machine statically charged.

Such charging can pose risks to users and operators. Electrostatically charged plastics attract dust, stick together, are difficult to print and, at high field strength discharge sparks which, despite being harmless physiologically, can hold sufficient energy to ignite explosive media.

Typical areas of application

Additives with an antistatic effect can reduce surface or contact resistance to the extent so that charges can discharge sufficiently fast. This is realized by the use of permanently effective or migrating antistatic masterbatches of various kinds.

Migrating antistatic masterbatches require a certain surrounding moisture in order to develop the corresponding effect. In addition to conductive carbon-based materials such as carbon black and graphite, conductive polymers such as polyether polymers or polyaniline play an increasingly important role amongst the permanently effective materials.

They allow any desired colouring of the materials, and form an ion-conducting cross-linking network in the basic matrix.

Benefits

BUSS compounding systems offer the following specific benefits for processing antistatics

Compounding requirementsof antistatics

The compounding of antistatic concentrates is an extremely wide field, just as wide as the variety of additives used and their effects. Thus, specific conductive properties are striven for in the end product and often combined with further properties such as colours.

The extremely wide field of requirements, which can range from high loads, various aggregate conditions of the additives to shearing and temperature-sensitive base and end products requires a system which can be used universally. The BUSS Co-Kneader is viewed to be the system with the best all-rounder qualities.

The design freedom for the system also enables taking specific changing requirements into account in the process zones with individually selected configurations. This enables the achievement of maximum quality and throughput.

The easy accessibility due to hinged or mobile casing allows extreme product sequences whilst retaining high availability. The widely supported BUSS process expertise makes the BUSS Co-Kneader a safe and future-proof choice for compounding antistatic compounds.

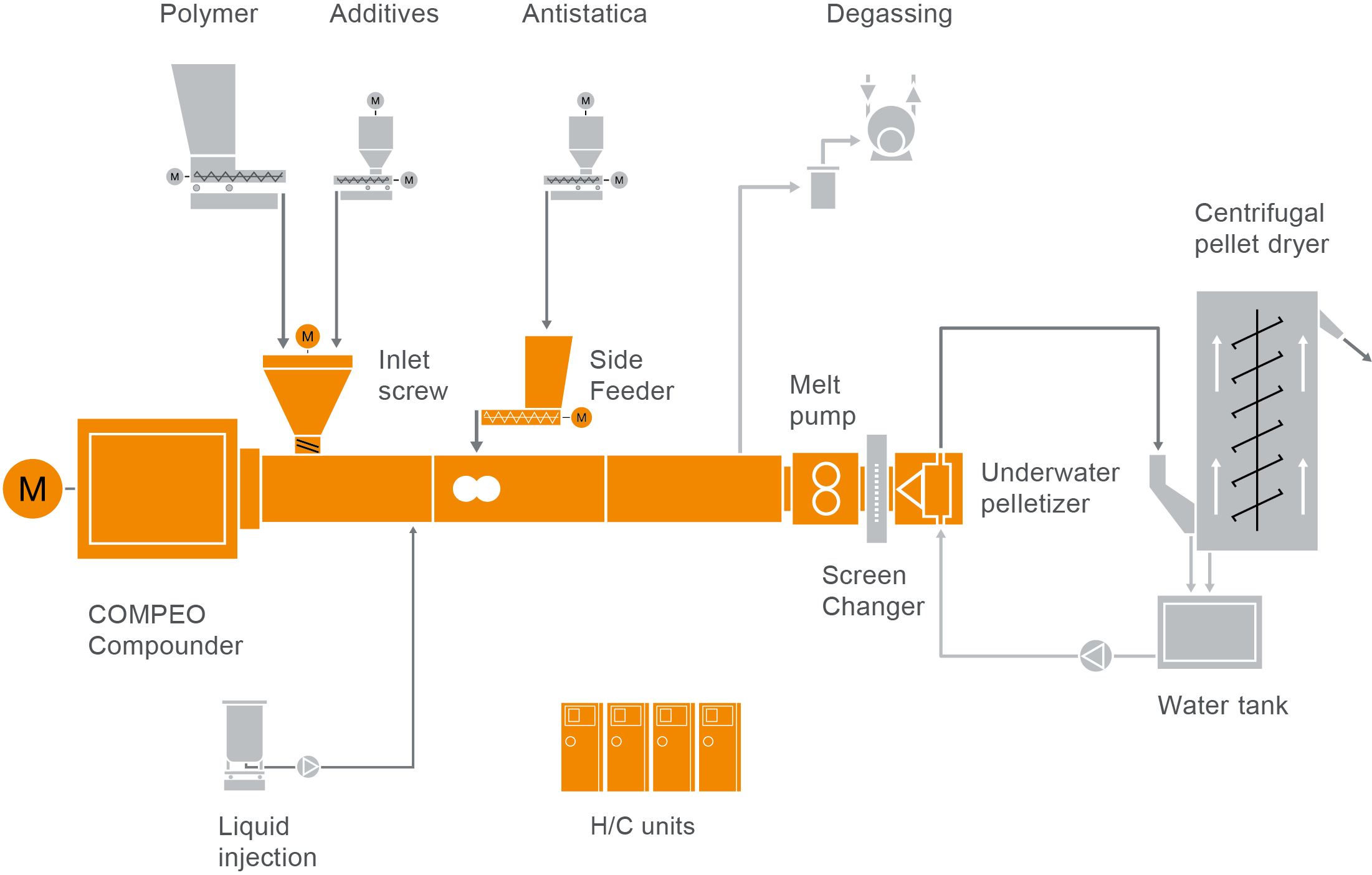

Typical plant layout

COMPEO compounding system configuration for antistatics compounding

Take a look at our typical plant layout for the production of antistatic compounds in our COMPEO showroom.

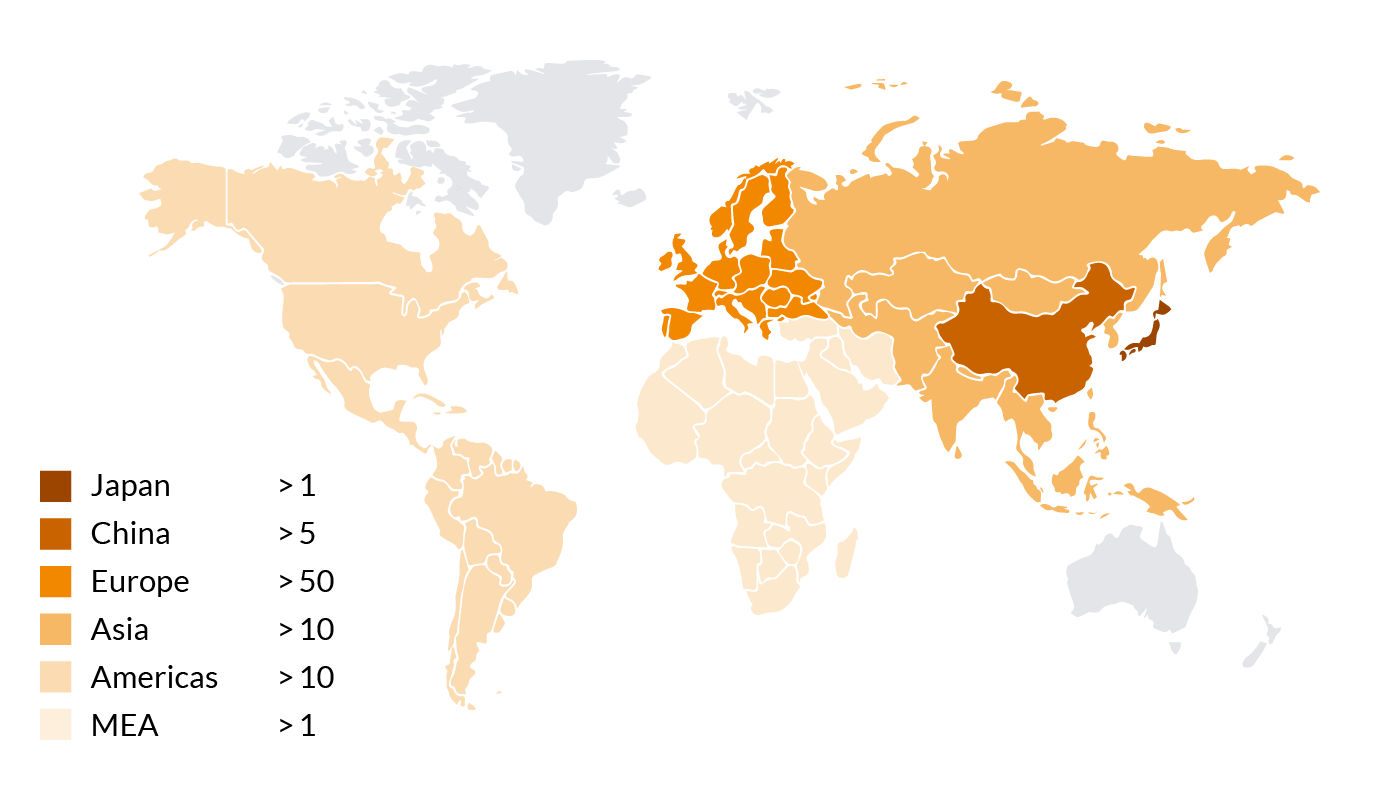

BUSS Co-Kneadersworldwide

Our patented Co-Kneaders are used worldwide nowadays, supporting our customers in the production of plastics. Using the BUSS compounding systems, our customers can master all the demanding requirements for compounding compounds with antistatic additives.

Number of Co-Kneaders used for antistatics compounding