For the industrial manufacturing of aluminum, which is considered the most important non-ferrous metal, so-called anode paste is of central importance.

Several use options exist due to the outstanding properties of aluminum:

- Such as the high specific rigidity, making components with identical rigidity only half as heavy compared to steel. This is particularly appreciated in lightweight, aircraft and vehicle construction.

- The excellent electrical and heat conductivity make it a preferred material for electrotechnology and energy transmission.

- Aluminum is a versatile material, which is characterised by its resistant oxide layer. This renders additional protective paintwork redundant, because the material is resistant against "normal" environmental factors such as oxygen, saline water, heat and cold.

- The high recyclability of aluminum plays an important role in many applications.

The process of aluminum electrolysis with anode paste

Following oxygen and silicon, aluminum is the third most common element in the geosphere and the most common metal in the Earth’s crust. It only exists in compounds. At the beginning of the 19th century, it became possible to extract it in a more pure form and in 1886 Charles Martin Hall and Paul Héroult developed melt flow electrolysis more or less simultaneously and independent of each other.

This process, named after them, is still the standard industrial process today, with several improvements. Basically, this process consists of a redox reaction, which is forced by applying a DC voltage source: the aluminum oxide extracted from bauxite is provided with carbon as a reducing agent.

This carbon is fed continuously by anodes, combines to CO and CO2- gases and burns off accordingly. The reduced aluminum accumulates at the cathode and can be discharged. Approx. 500 kg gross weight anode is required to produce 1 t aluminum. Pure electrodes, such as those used in the electrolysis described above, can only be produced using special types of coke.

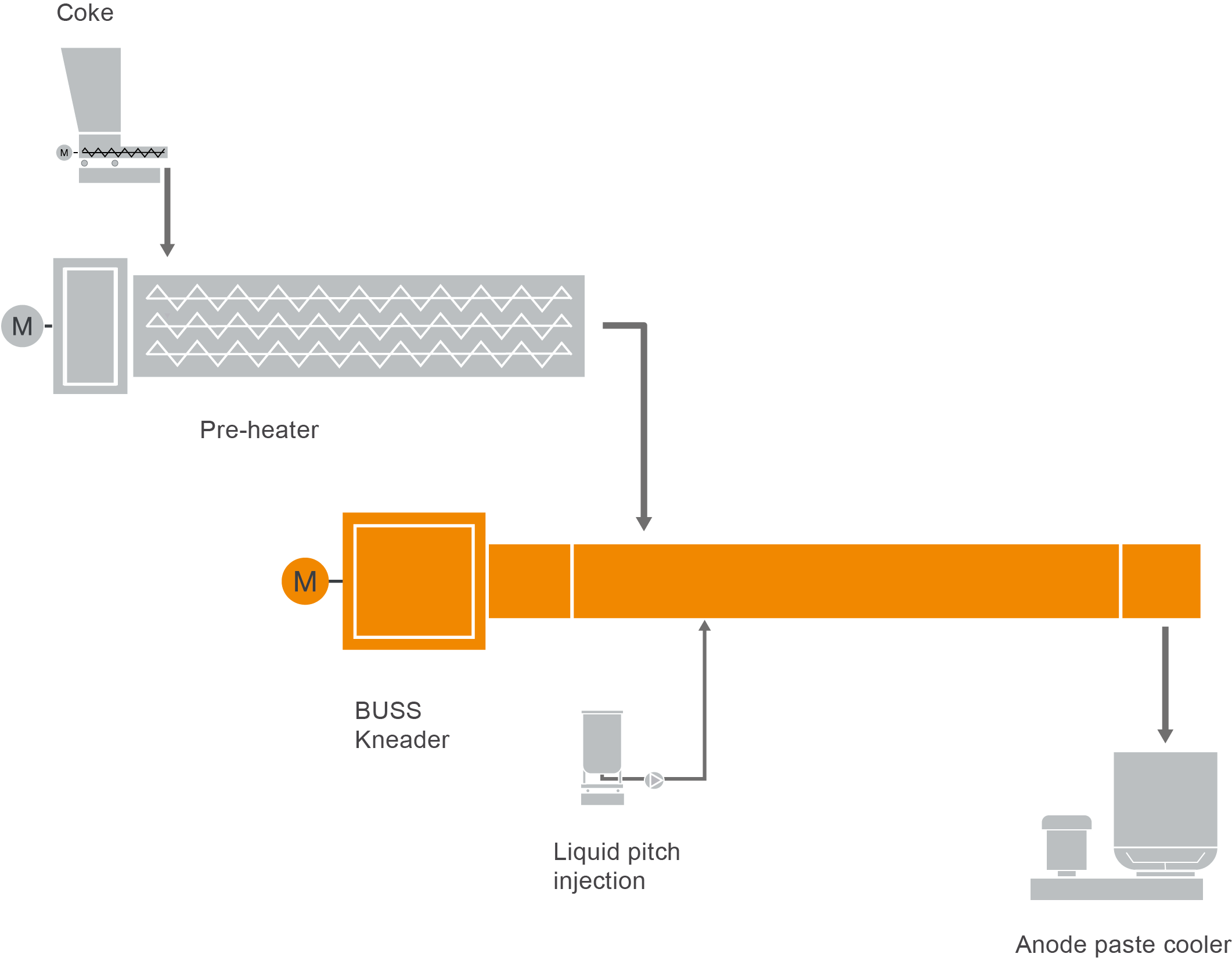

Therefore, petroleum coke fraction which is available in larger quantities, is used. Coal tar pitch is added to the coke as a binding agent. This grind remains as a residue during tar distillation. At normal temperatures, it is solid and can be crushed easily.

Under the influence of heat, it melts to become a low-viscosity liquid with a melt point of 95° to 120°C, dependent on its molecular weight. An appropriate preparation line is required for the extraction of the base material for electrode production with the correct composition. The petroleum coke delivered is pre-crushed, dried carefully, ground, screened, sifted and strictly separated by grain size and put into intermediate storage in various bunkers.

Specific fractions of the coke grain are accurately dosed according to specified recipes, pre-heated and mixed with the tar pitch in heated BUSS Co-Kneaders. The tar pitch is injected directly into the process room and has the task of encasing the coke grain penetrating its pores and joining them to form a paste-like or viscous paste.

After leaving the Co-Kneader, the paste is processed as block anodes, dependent on its use, using vibrating compactors (for pre-baked anodes) or then as coal briquettes (for Söderberg pots). The electrolysis process runs continuously and is not interrupted. The anode supply must be ensured at all times. The use of so-called “proven technology” and therefore maximum compounding system reliability is crucial.

Benefits

The advantages of the BUSS compounding technology preparing anode paste

Compounding requirementsfor anode paste

The BUSS Co-Kneader has already been the choice compounder technology for the preparation of anode paste since the 1950s. The output capacity of originally 4 t/h to nowadays more than 60 t/h can be handled excellently by the compounding system.

Due to technology and process optimisation, the increased requirements due to higher direct current (> 500 kA) and worsening raw material qualities could be met extremely successfully or even anticipated over the past years.

The advantages of the BUSS technology compared to alternatives can be summarised as follows:

Each coke particle is subject to identical mixing intensity in the continuous mixing process and dwell time via the very easily controllable kneading process. The gentle mixing process enables the anode paste particle size distribution to be upheld exactly. This enables excellent physical properties for the anode blocks and optimum burn-off behavior in electrolysis.

The 2 available machine sizes cover the required throughput performance of 20-65 t/h. The reliability, availability of wear and tear parts and services throughout the entire duty cycle of the BUSS Co-Kneader and the complete compounding system, mostly covering a period of several decades, are legendary. The several hundred plants in the field and continuous new installations bear impressive witness to this.

Typical plant layout

BUSS Co-Kneadersworldwide

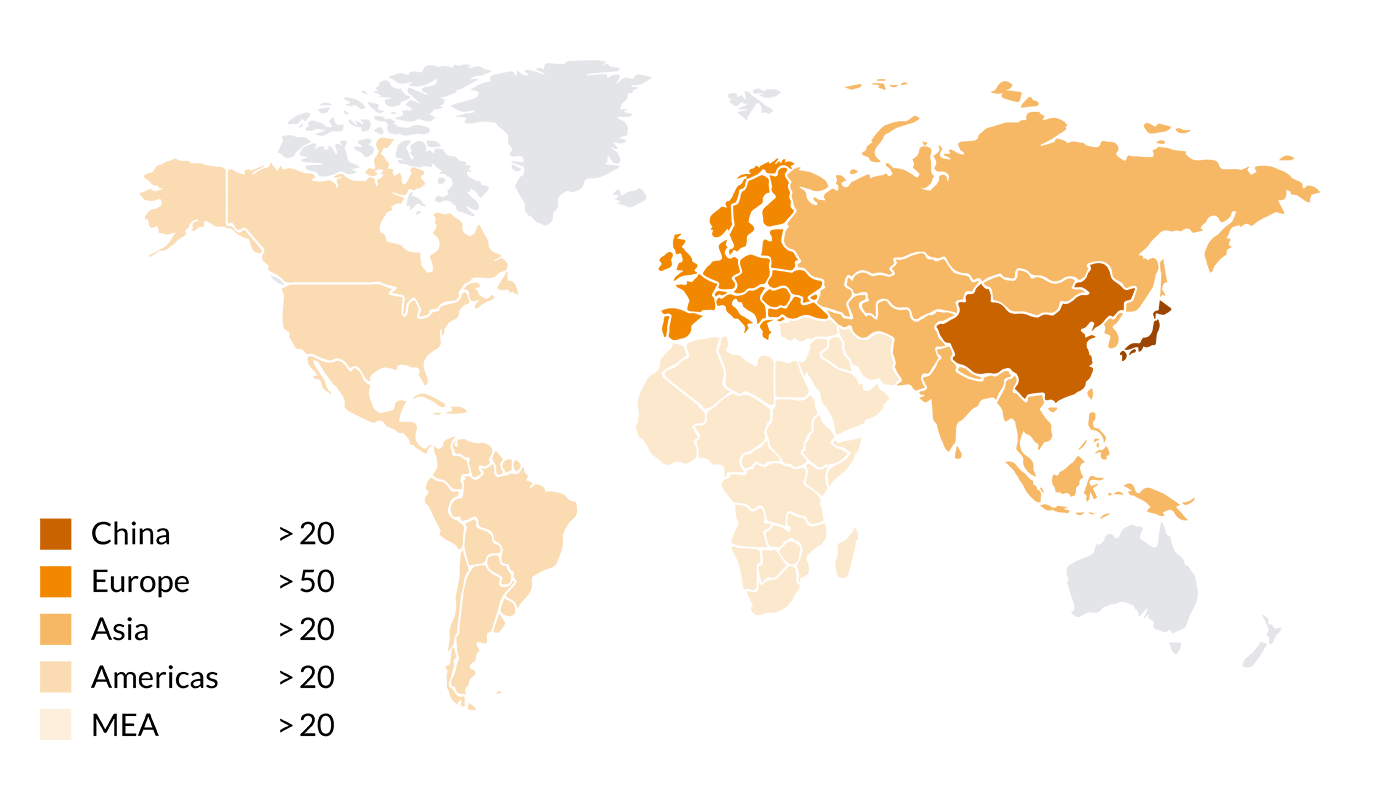

Our patented Co-Kneaders are used worldwide nowadays, supporting our customers in the production of aluminum. Using the BUSS compounding systems, our customers can master all the demanding requirements for anode paste compounding.

Number of Co-Kneaders used for anode paste compounding