Polyolefins have excellent insulation properties, but are also highly flammable and must be made flame-retardant accordingly. At the beginning of the 1980s, alternatives to the PVC compounds used practically exclusively so far were first developed.

This development was also driven by the public concern about the release of dangerous substances in general and specially in cases of fire.

Recently, the stricter European Construction Products Regulation (CPR) came into force. Its target is to reduce the risk of fire further, to retard the spread of fires, to minimize the formation of flue gas and to offer diverse protection for people, objects and the environment.

HFFR cable compounds which are manufactured using BUSS compounding systems meet these European safety standards.

In many cases, flame-retardants based on light metal hydroxide (ATH, MDH) are the best choice for meeting the standardized requirements for HFFR cable compound masses. During the course of time, further impact concepts and materials such as ground minerals and also Nano fillers were included. In the meantime, the original high-priced speciality has become a mass product which is almost at the same price level as PVC compounds.

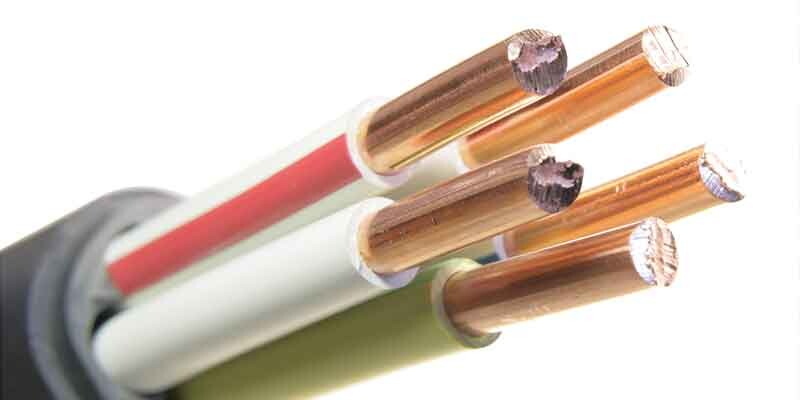

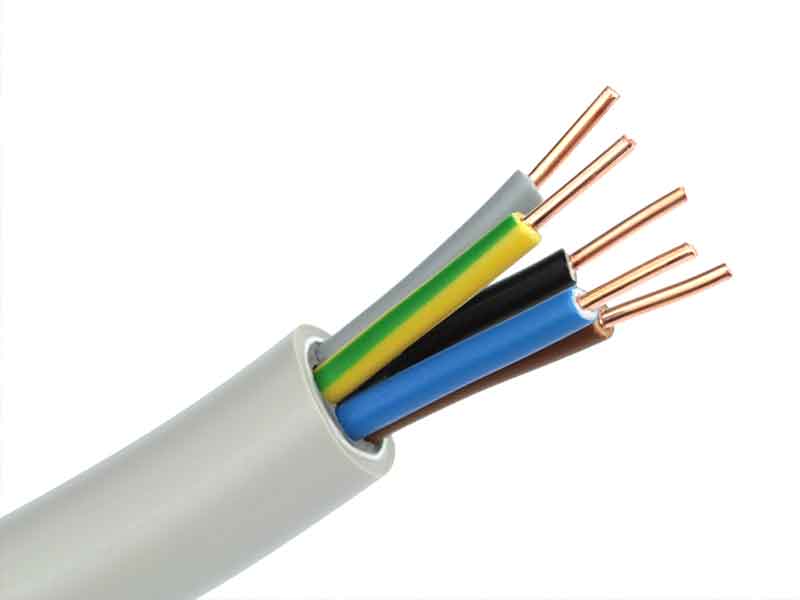

Typical areas of application for HFFR cable compounds

The legislative regulations described above prescribe the use of HFFR cable compounds in Europe in public buildings and installations such as buildings, tunnels and public transport. We expect similar regulations to apply in India, China, and the Middle East in the future.

In the plant and machine construction its application for complex and safety-relevant facilities such as power plants, industrial, chemical and pharmaceutical plants, data centers, etc. has been implemented in order to reduce risks and consequential damage.

The demanding flame-retardant properties of HFFR cable compounds normally requires the addition of 50-70 % flame-retardant. In some application cases, even in excess of 80%. These include, for example, insulation panels for building cladding. Challenges regarding the further physical properties, compounding, processing to cable and final use arise from this.

Therefore, PE copolymers are selected for the formulations which enable good filler absorption. Coupling and partially also conductive network systems are integrated in order to achieve mechanical and application-relevant properties. The BUSS Kneader combines the requirements of mixing high filler content at low temperatures and the relevant compounding for manufacturing HFFR cable compounds here.

Benefits

BUSS compounding technology offers the following specific advantages for processing HFFR cable compounds

Compounding requirementsfrom HFFR

Excellent dispersive and distributive mixing processes at low product temperatures are a prerequisite for the compounding process in order to provide the high content of flame-retardants and additives as required. Multiple splitting of the dosage flows as well as the liquid injection of reactants and lubricants in defined positions are part of the requirement profile.

The BUSS Kneader’s specific capabilities in this field are highly effective, as already mentioned above. Due to the operating principle, the enormous number of mixing cycles at moderate and uniform shear rates enables unsurpassed mixing efficiency and therefore product quality with maximum throughput.

As a side-effect of the moderate shear rates, wear and tear is significantly lower than with other screw extruders. The process zone has a modular structure and is designed application-specifically by our in-house experts. It can at all times be adapted to changing conditions when compounding HFFR cable compounds at all times.

The positioning of the liquid injections at almost all possible locations serves as a process design parameter in order to influence the reactive processes in a targeted manner.

The process can be monitored by corresponding temperature measurements in the process area. This allows online quality assurance and regulation. With the two-stage BUSS Kneader system, compounding and pressure build-up are strictly decoupled from each other. This enables independent optimization of the process steps. The hinged BUSS Kneader housing or retractable housing of the discharge extruder enables fast access and high system availability.

The modular and therefore adjustable structure of the entire line, and the widely supported BUSS process expertise, make the BUSS Kneader an excellent choice for HFFR cable insulation mass compounding with maximum investment security.

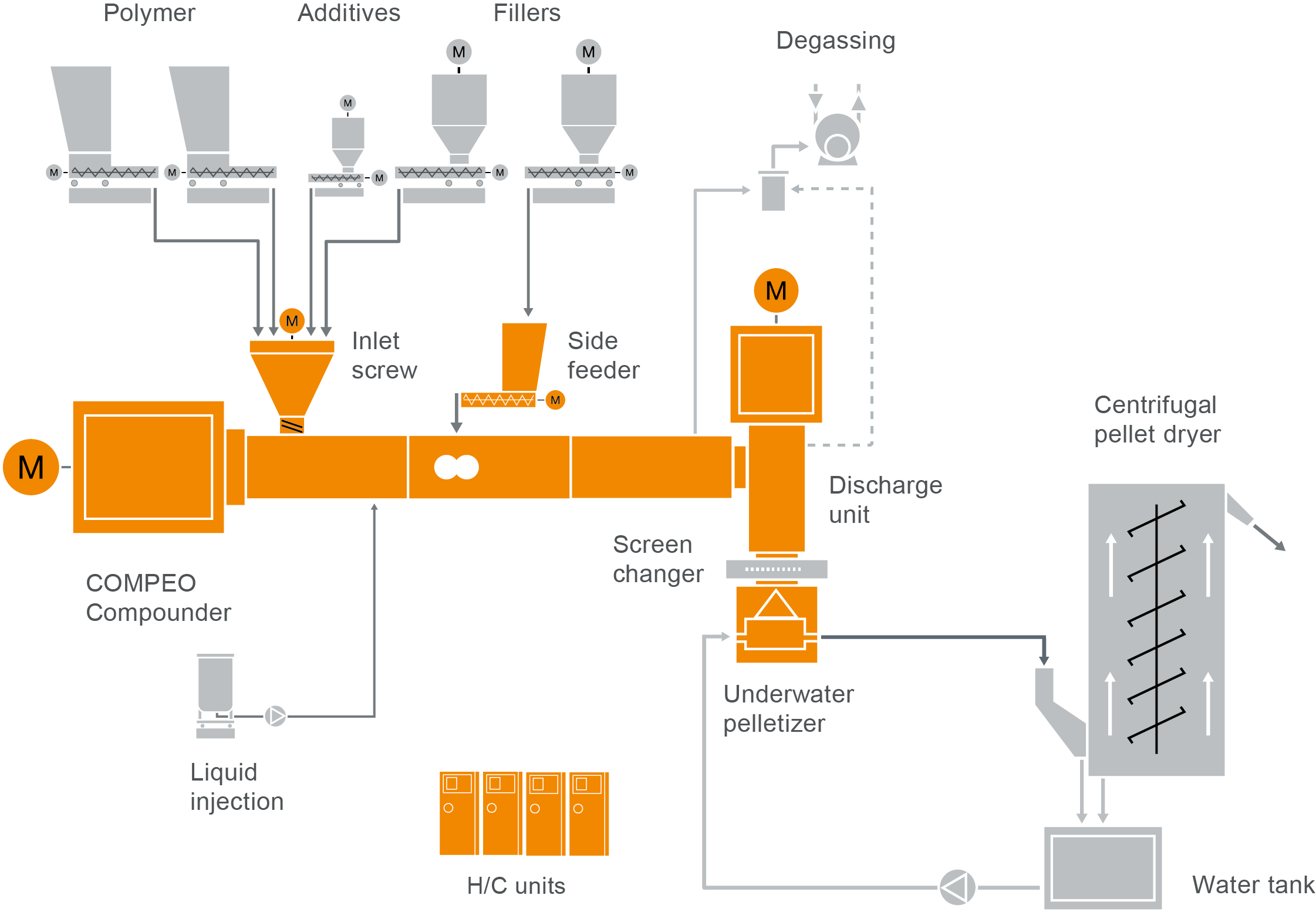

Typical plant layout

COMPEO plant layout for the manufacturing of HFFR cable compounds

Take a look at our typical plant layout for HFFR compounds in our COMPEO showroom.

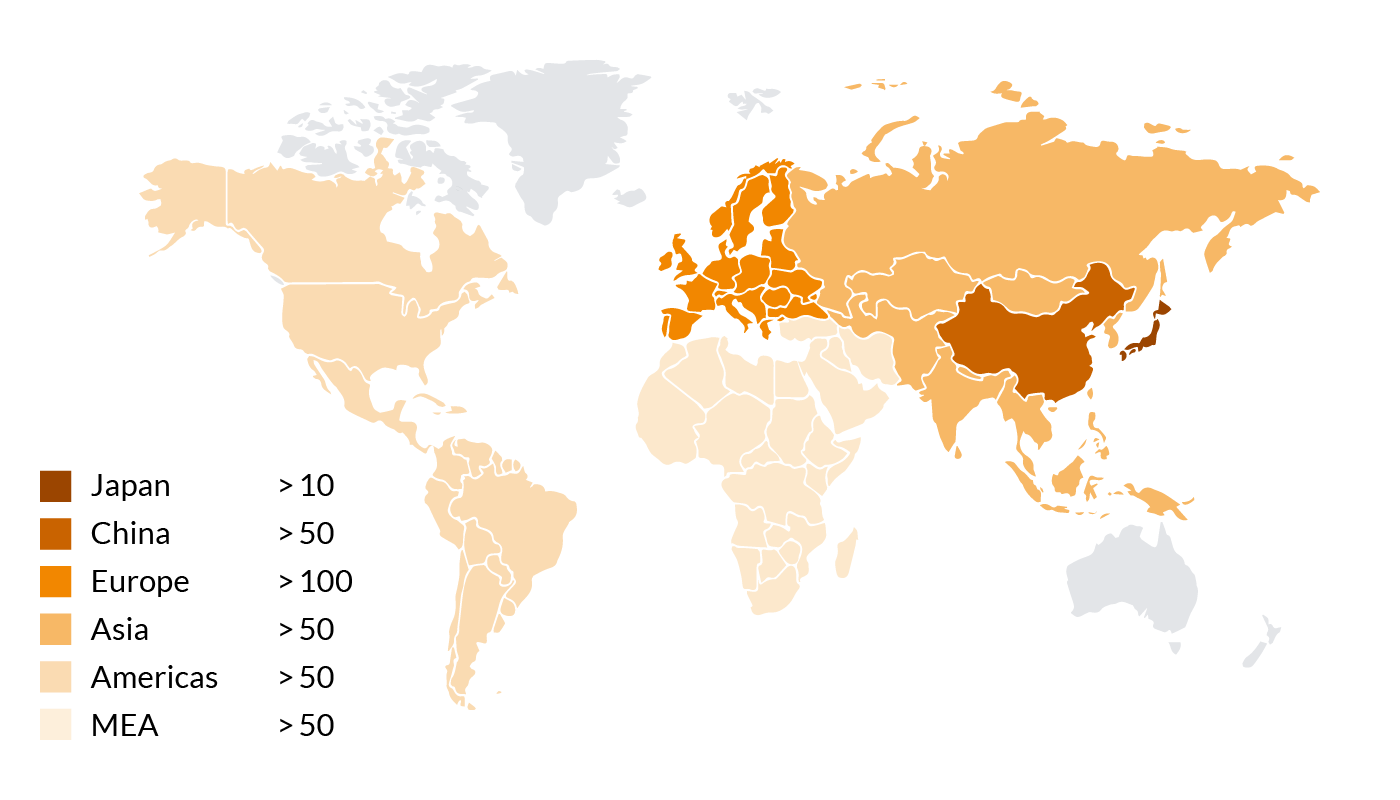

BUSS Co-Kneadersworldwide

Our patented BUSS Kneaders are used worldwide nowadays, supporting our customers in the production of plastics. Using the BUSS compounding lines, our customers can master all the demanding requirements for manufacturing HFFR cable compounds.

Number of BUSS Kneaders used in the cable industry